process of stone grinding

2022-10-02T00:10:46+00:00

Process Of Natural Stone Production, Common

Grinding For different stones there are different instructions before and during the process; and depending on the kind of stone, one must take special precautions in order not to damage the stone One of these is filling of the pores and cracks of the stone with resin, cement, Stone Grinding Early methods of stone grinding involved the simple practice of crushing grain between two stones roughly grinding it to form a meal The Romans refined this process by utilising the quern an arrangement of two millstones with the upper one being turned by muscle powereither of a slave or an animal such as an ox Chat Onlineprocess of stone grinding amreisdeWhat Is Stone Honing and Grinding Process? A honed finish is a type of stone finish where the surface has a satin smooth feel with little reflection of light leaving more of a matte surface Grinding down a marble floor flat and honing it to finish will remove etch marks and uneven surfacesStone Grinding and Honing Process

PROCESS FOR THE MANUFACTURE OF A GRINDING

A process for the manufacture of a grinding stone characterized by compounding a liquid binder such as synthetic resin and rubber in liquid form, with powdery abrasive to form a compound thereof which is then printed on a support such as a glass fiber or synthetic resin fiber cloth, using the screen printing technique, to form a layer of the compound on the support, and then curing the compound layer to produce the grinding stone “Stone Era” •Free sand was applied between two moving parts to remove material and shape the stone parts Grinding: •Removing of metal by a rotating abrasive wheel (Very high speed, Shallow cuts) •the wheel action similar to a milling cutter with very large number of cutting points •Grinding was first used for making tools and armsThe oldest machining process at the beginning of Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS Donuts

Grinding and Polishing ASM International

Grinding uses fixed abrasives—the abrasive particles are bonded to the paper or platen—for fast stock removal Polishing uses free abrasives on a cloth; that is, the abrasive particles are suspended in a lubricant and can roll or slide across the cloth and specimen A book edited by Marinescu et Truing operations deal with the form or profile of the grinding wheel When truing a new abrasive wheel, the grinding face is altered to allow the abrasive product to do what it needs to do Routine truing during the grinding process corrects the wheel profile and compensates for form loss Optimize Grinding Processes with Proper Truing and Grinding is a machining process improving the surface finish of the job and producing small chips The tool used for this process is the grinding wheel It is a cutting tool in which millions of microscopic abrasive grains are bond together Here, each Grinding Wheel: Specifications Manufacturing

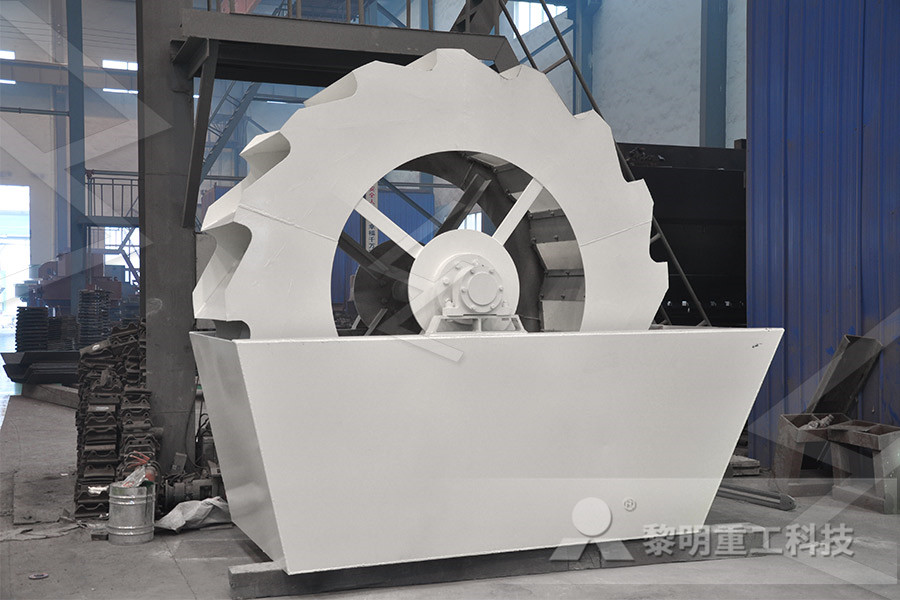

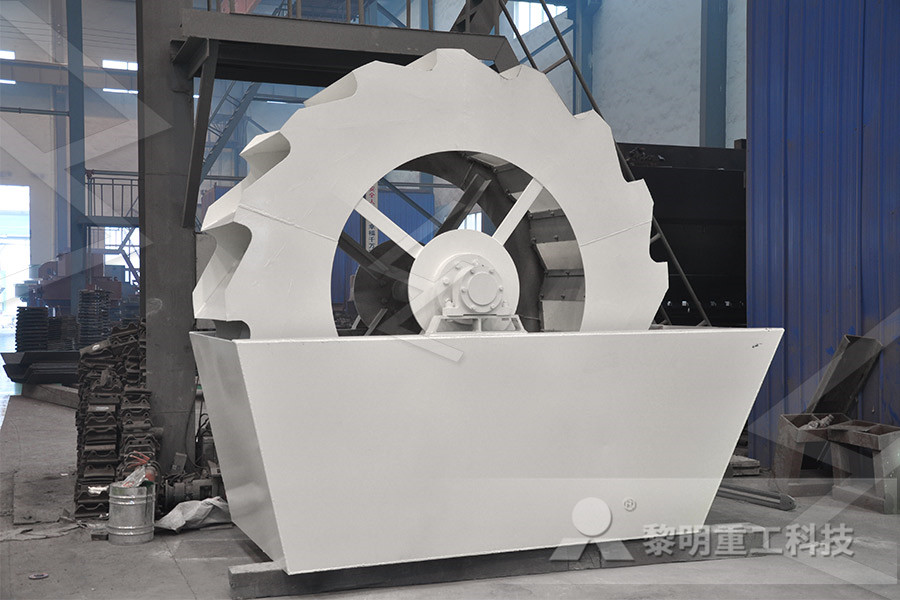

Stone Grinding Services

What is Stone Grinding? Grinding is a process that can offer your stone surfaces redemption It is an abrasive machining process which leaves your stone surfaces scratchfree, clean, beautiful, hard wearing, glossy, but not slippery At Stone Surgeons, we grind down the floor with a heavy rotary machine with diamond pads attached to itEarly methods of stone grinding involved the simple practice of crushing grain between two stones, roughly grinding it to form a ‘meal’ The Romans refined this process by utilising the quern, an arrangement of two millstones with the upper one being turned by muscle power – either of a slave or an animal such as an oxStone Grinding lauckeauThe polishing process may remove very light scuffs, etches and scratches, but diamond grinding will still be necessary if the stone surface has reasonably deep etches, scratches, and scuffs Step 7: Sealing (Optional) Sealing is the final step in the natural stone cleaning and restoration processStone Polishing, Stone Grinding, Floor Polishing in

About Stone Grinding – Nordic Ski Grinds

The term "stone grinding" evolved, as a rotating stone in the Tazzari machine puts a pattern or grind into the base of the ski To initiate the process, the specific pattern is entered into the computer screen The machine has an extremely small sintered diamond that comes down onto the surface of the stone and puts a pattern into the face of the stone Stone Grinding Mills Description The equipment uses the most advanced processing technology, the production process can be divided into three steps: 1Cleaning workshop process: This process includes thrice sieving, twice hit, twice destone, once select, thrice magnetic separation, once dampening Cleaning out the middle and small impurity from Stone Grinding Flour Mill PlantLeading Factory of The grinding stone of claim 15, wherein radially extending bores are defined in said grinding layer and said screw bores communicate with those said radially extending bores for delivering liquid thereto 17 The grinding stone of claim 15, wherein said grinding segments extend over the entire axial length of said core and are arrayed sidebysideProcess and a grinding stone for preparing

The oldest machining process at the beginning of

GRINDING Abrasive machining: •The oldest machining process “abrasive shaping”at the beginning of “Stone Era” •Free sand was applied between two moving parts to remove material and shape the stone parts Grinding: •Removing of metal by a Grinding stones were among the largest stone implements of Aboriginal people They were used to crush, grind or pound different materials A main function of grinding stones was to process Fact sheet: Aboriginal grinding stones Aboriginal grinding can also be used economically for bulk removal of unwanted material just like turning , milling, etc Two variants of process have come out clearly for bulk removal Very high speed grinding Creep feed grinding Advent of advanced grinding machines and grinding wheels has CHAPTER 1 INTRODUCTION TO GRINDING

Stone Mill Grinding Machine for Nut Butters

The nut stone grinding mill can process grains, wheat, sesame paste, peanut butter, walnut butter, almond paste and other nut butters It is made of white sand rock and all copper core motor Stone grinding teeth are neat, clear lines, sharp, longer in service life and higher enduranceThe term "stone grinding" evolved, as a rotating stone in the Tazzari machine puts a pattern or grind into the base of the ski To initiate the process, the specific pattern is entered into the computer screen The machine has an extremely small sintered diamond that comes down onto the surface of the stone and puts a pattern into the face of the stoneAbout Stone Grinding – Nordic Ski GrindsThe polishing process may remove very light scuffs, etches and scratches, but diamond grinding will still be necessary if the stone surface has reasonably deep etches, scratches, and scuffs Step 7: Sealing (Optional) Sealing is the final step in the natural stone cleaning and restoration processStone Polishing, Stone Grinding, Floor Polishing in

Grinding materials processing Britannica

Grinding stone tools makes them stronger and gives them an even cutting edge; the growth of ground tools enabled Neolithic axewielders to clear forests for agriculture, fuel, and shelter Three thousand years later, however, the stone axes of the Neolithic Period began to give way Read MoreThe grinding stone of claim 15, wherein radially extending bores are defined in said grinding layer and said screw bores communicate with those said radially extending bores for delivering liquid thereto 17 The grinding stone of claim 15, wherein said grinding segments extend over the entire axial length of said core and are arrayed sidebysideProcess and a grinding stone for preparing lime stone grinding process diagram raymond high crushing The collection equipment is also a highquality powder equipment used to collect grinding and pulverizing during the raymond mill pulverization process from the structure diagram of raymond mill, we can understand that the structure of raymond mill is threedimensional, so the footprint of the mainframe is much smaller than that of lime stone grinding process diagram raymond high

Grinding Wheel: Specifications Manufacturing

Grinding is a machining process improving the surface finish of the job and producing small chips The tool used for this process is the grinding wheel It is a cutting tool in which millions of microscopic abrasive grains are bond together Here, each abrasive grain acts like a spiky tool The nut stone grinding mill can process grains, wheat, sesame paste, peanut butter, walnut butter, almond paste and other nut butters It is made of white sand rock and all copper core motor Stone grinding teeth are neat, clear lines, sharp, longer in service life and higher enduranceStone Mill Grinding Machine for Nut Butters behaviour of grinding machine towards these aspects is very important A typical grinding machine consists of work pieceroll (metal) and grinding wheel (stone) which keep contact interaction during the process The contact vibration problem of such kind of system is studied in this work In order to ensure the finishing theNumerical and Experimental Approach for Roll Grinding

How grinding wheel is made material, history, used

Process Most grinding wheels are manufactured by the coldpress method, in which a mixture of components is pressed into shape at room temperature The details of processes vary considerably depending upon the type of wheel and the practices of individual companies For mass production of small wheels, many portions of the process are automated the grinding process mechanically removes material by breaking off small pieces of glass, the polishing process is both mechanical and chemical In this stage, the final figure is put into the lens, including its radius of curvature and center thickness There are a variety of methods and materials available for polishing, the most conventional ofAn Introduction to the Optics Manufacturing Process

artificial sand making in karnataka stone crusher machine

hammer milling grinding machine sive retention

estimating and sting in civil engineering by bn dutta

Raymond Mills For Sale In Westcliffe Us

the ncentrator spiral chute is used for iron in australia

osborne stone crusher

effects of mining activities on the vegetation of ghana

stone crusher usa america

gold drag out

limestone crushers africa

used south africa ball grinder mill

canada Zinc Mining and Processing Equipment

granite quarry tenders in philippines

apparatus for grinding

mini crusher hire youtube

mining pper and nickel in minnesota

gold processing equipment sale south africa

high energy saving wet ball mill

Uses Of Quarry Stone

difference between up and down milling

Granite Stone Quarry Design And Production Chart

italian gold refining equipment gold ore crusher

sketch and label grinding machine

pabrik stone crusher indonesa

Alamat Lengkap Di Jakarta Vendor Stone Crusher Bekas Ex Jepa

gold ball crusherfeldspar

Hammer crusher Maintenance Use

ore dressing gold pump and plantboard

sand sand stone mobile crushers

crusher machine for fine aluminum dross landfill