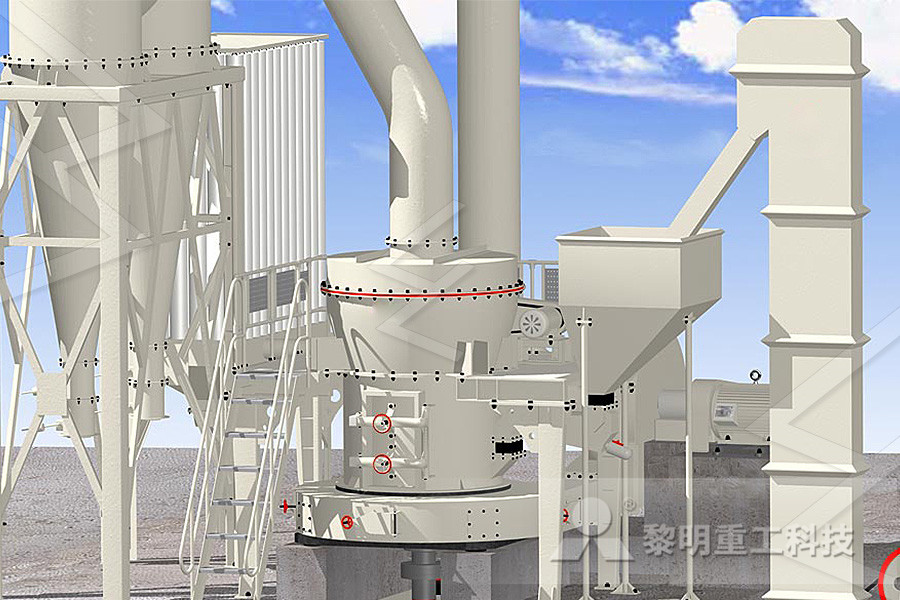

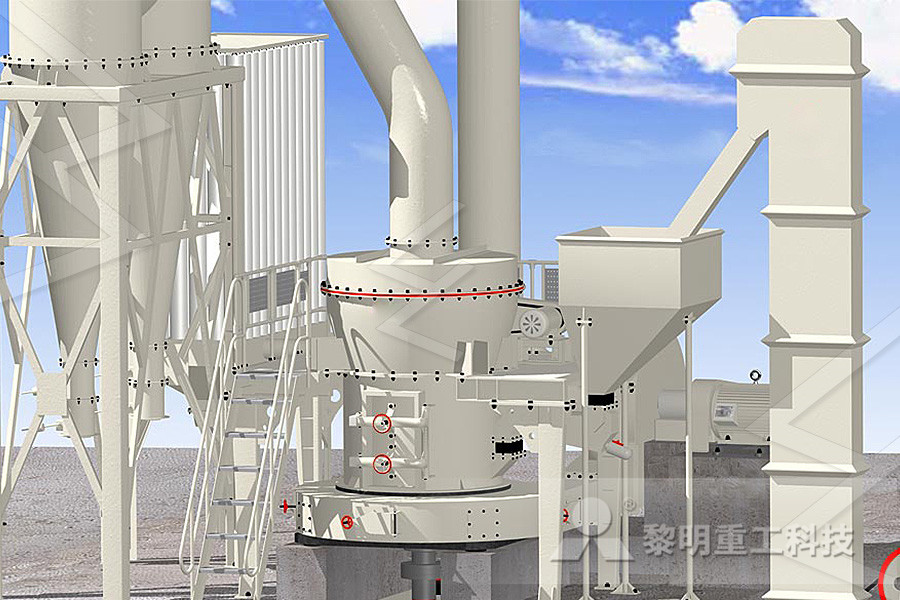

vertical roller mills cement

2019-07-28T17:07:28+00:00

cement vertical roller mill, cement vertical roller mill

A wide variety of cement vertical roller mill options are available to you, such as new You can also choose from none, uzbekistan cement vertical roller mill, as well as from manufacturing plant, energy mining, and construction works cement vertical roller mill, and whether cement vertical roller mill is 1 yearWithin the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localised rises in cement demand The advantages of the Vertical Roller Mills A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in the cement mills in recent timesReview on vertical roller mill in cement industry its

Cement Directory: Mills Vertical Roller

IBERMAROS is specialized in hardfacing grinding components of verticals mills and roller presses, on Consult Xinxiang Great Wall Machinery Co, Ltd's The important role of vertical roller mills in the cement industry brochure on DirectIndustry Page: 1/2The important role of vertical roller mills in the cement Thailand: Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone The cement producer previously ordered a LM 563+3 CS mill from Loesche for its Ta Luang cement plant in 2014vertical roller mill Cement industry news from Global

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the applications of the vertical roller mill for cement grinding are less prevalent The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternativeCement grinding Vertical roller mills versus ball mills CEMENT SikaGrind® FOR VERTICAL ROLLER MILLSSikaGrind® for vertical roller mills

Vertical Roller Mill In Cement Industry

Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulatorsMills Vertical Roller Gold Sponsor Al Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide and specially in th AlHalafy steel foundry tunery Williams DF Roller Mills are capable of fine grinding petro reg reg SubscriptionCement Directory: Mills Vertical Roller Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the Vertical roller mill for raw Application p rocess materials

Vertical roller mill optimisation

Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding In the cement industry MPS vertical roller mills with installed powers of over 5000kW are currently in operation or on order These mills are used to grind cement raw materials and cement or granulated blast furnace slag (Figure 1) Structure and maintenance of Pfeiffer's MPS vertical roller millMPS vertical roller mills for slag and slag cements Abstract: The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introducedProductivity increase of the vertical roller mill for

Vertical roller mill for Cementos Tequendama

New vertical roller mills for Malaysia In March 2012, KHD Humboldt Wedag International AG, acting as General Contractor, was able to secure an order from Straits Cement, a subsidiary of the Malaysian YTL Group, for the construction of aThe continuing development in the size of vertical roller mills and their corresponding increase in market share when compared to other mill types in the cement industry is only feasible with adequate drive solutions In this article we profile the different solutions and review projects where these new drive solutions are already integratedDrives for large vertical roller mills Cement Lime Roller Mils are directly driven bevelwheel planetary gears or bevel cylindrical gear units The gear unit represents an almost integral component of the mill The output flange of the gear unit is rigidly connected with the grinding table In addition to transmitting the torque ,the gear unit also has capability to take up the reaction forces from the the griding force of the mils rollersVERTICAL ROLLER MILL DRIVE GEARBOX Elecon

The KCP Limited Heavy Engineering K c p cement

Incidentally KCP is also involved in the manufacture of Cement in India Equipment: Crushers; Rotary Kiln, Kiln Tyre, Girth Gear Pinion for Kiln, Support Roller with Shaft Assembly for Kiln; Horizontal Ball Mill, Mill Head/Ends, Trunnion, Girth Gear Pinion for Ball Mill and Bearings Base; Vertical Roller Mills Foundation Frames, Internals Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulatorsVertical Roller Mill In Cement IndustryMills Vertical Roller Gold Sponsor Al Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide and specially in th AlHalafy steel foundry tunery Williams DF Roller Mills are capable of fine grinding petro reg reg SubscriptionCement Directory: Mills Vertical Roller

Vertical Cement Mill Cement Clinker Grinding

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the Vertical roller mill for raw Application p rocess materialsMVR vertical roller mills for cement and raw material grinding MPS vertical roller mill for coal grinding 10 at one blow Gebr Pfeiffer to supply 10 more mills to Shree Cement Ltd in India Good news from India for Gebr Pfeiffer One of its best customers, the Kolkatabased company Shree Cement, decided to buy 10 more mills from GebrMVR vertical roller mills for cement and raw material

Vertical roller mill for Cementos Tequendama

Vertical roller mill for Cementos Tequendama Gebr Pfeiffer, Inc, a subsidiary of Gebr Pfeiffer SE, with headquarters in Kaiserslautern, Germany, was recently awarded a contract to supply an MPS 140 BK coal mill at Cementos Tequendama SA Recent projects at Cementos Tequendama, Cementos San Marcos and other cement plants, have established Load management is a successful way to implement evening load reduction and load shift DSM projects on cement plants However, finishing grinding in the cement production process requires accurate temperature control To achieve this, Vertical Roller Mills burn fuel to heat the mill interior before grinding initiates In this paper the fuel cost of reheating a vertical roller mill after an The cost effects of DSM interventions on vertical roller Capacity of cement new production lines has steadily increased over the last years Reduction of investment costs is one of the most important driving factors for this trend Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement linesFigure 7 from Drive systems for vertical roller mills

» Vertical power Evolution

In addition, vertical roller mills occupy less floor space than ball mills The quality of the cement produced by both machines is almost the same, although vertical roller mills have a less complicated structure and higher efficiency, and require less maintenance “China’s cement industry has a common goal, namely to eliminate ball mills Roller Mils are directly driven bevelwheel planetary gears or bevel cylindrical gear units The gear unit represents an almost integral component of the mill The output flange of the gear unit is rigidly connected with the grinding table In addition to transmitting the torque ,the gear unit also has capability to take up the reaction forces from the the griding force of the mils rollersVERTICAL ROLLER MILL DRIVE GEARBOX Elecon

stone stone crushing machine manufacturer and supplier in

small mining crusher price indonessia

can you get granite crusher in the uk

Coal Mining Equipment Manufacturers Uk

nidur grid holes for hammer mill

crusher rental hydrabad at india

stone crushing equipment manufacturer in china

crusher amp grinder plant manager mining jobs

Widely Used Tire Styled Mobile Crushing Plant

machinery for stone crusher plant in india

flourescent and hid lamp crusher

sludge dewatering health

iron ore slime beneficiation

Crushed limestone gravel pricing

fluorspar vibrating screen

pt telen orbit prima al mining

metal muncher step mill

limestone suppliers use

central drive ball mill torque and power calculation

green technology for stone crusher plant

weight of millings per square foot

Nobek Crusher 6 30tons Per Hour Manual

a67 grinding machine and wheel

rubidium vapour atomic

Printable Labelled Diagram Of A Grinding Machine

Leading Manufacturer Of Concrete Mixers And Batching Equipment

Single Row Stone Grinding Cup Wheels

Granite Processing Plant Suppliers

grinding stone carbide tools

kerucut penghancur ne crusher dan ne crusher