tower grinding mill simulation

2018-11-21T01:11:58+00:00

TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

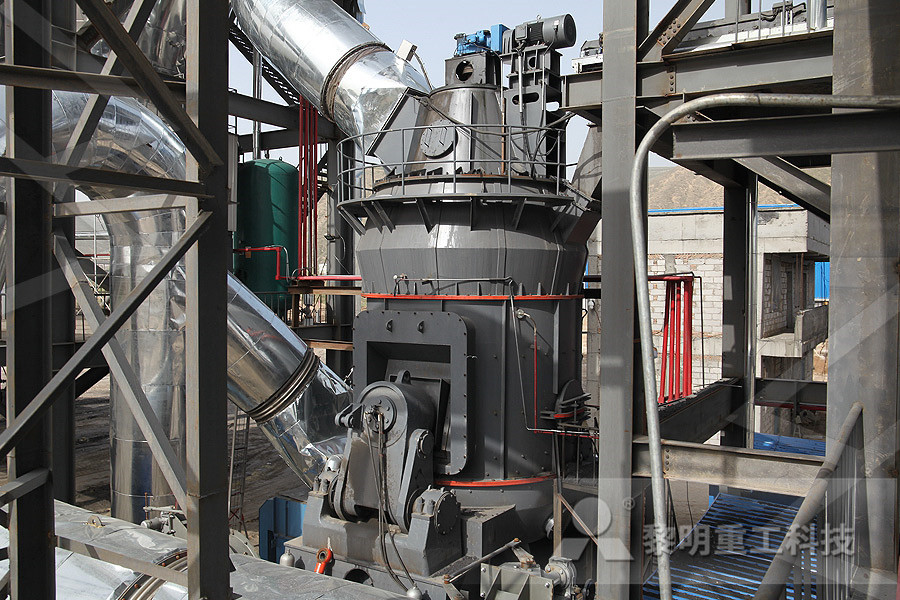

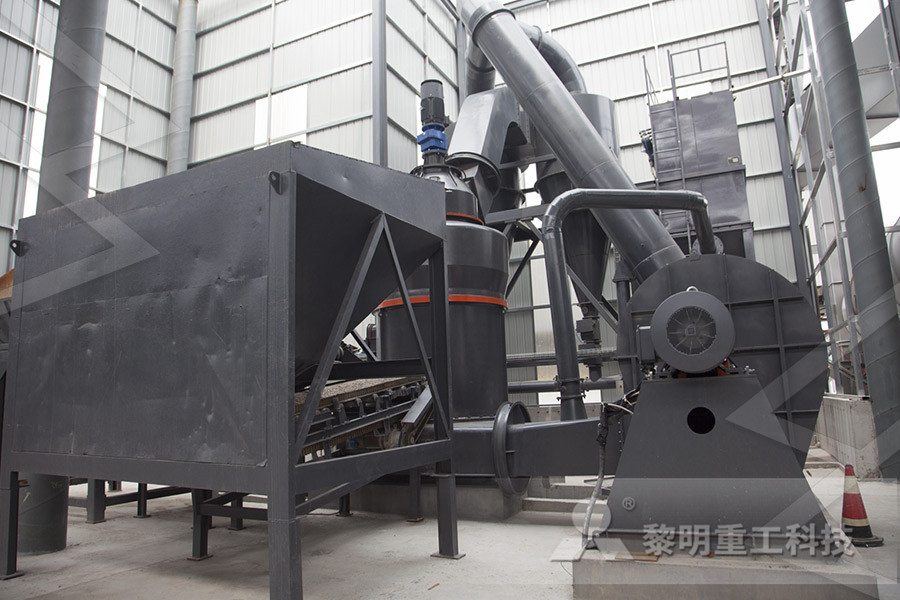

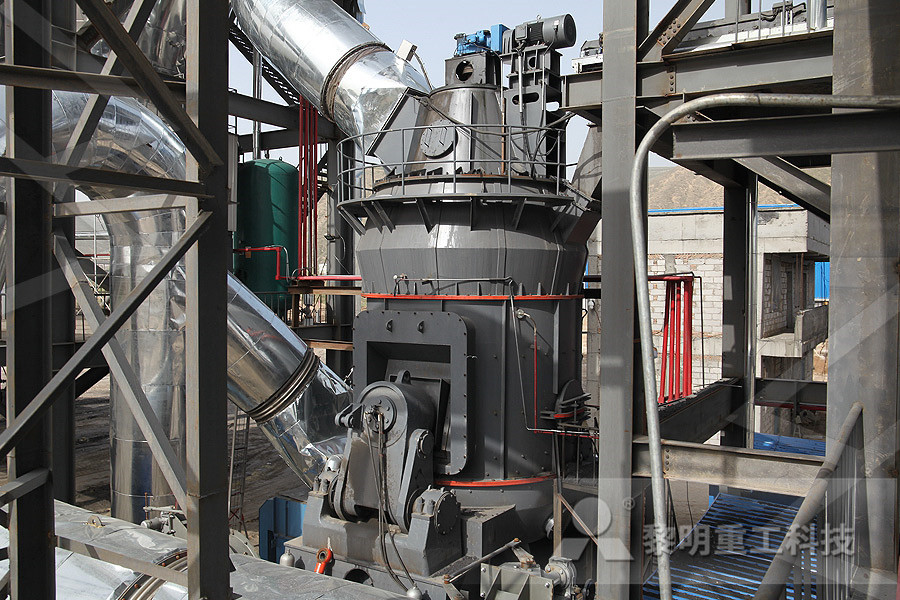

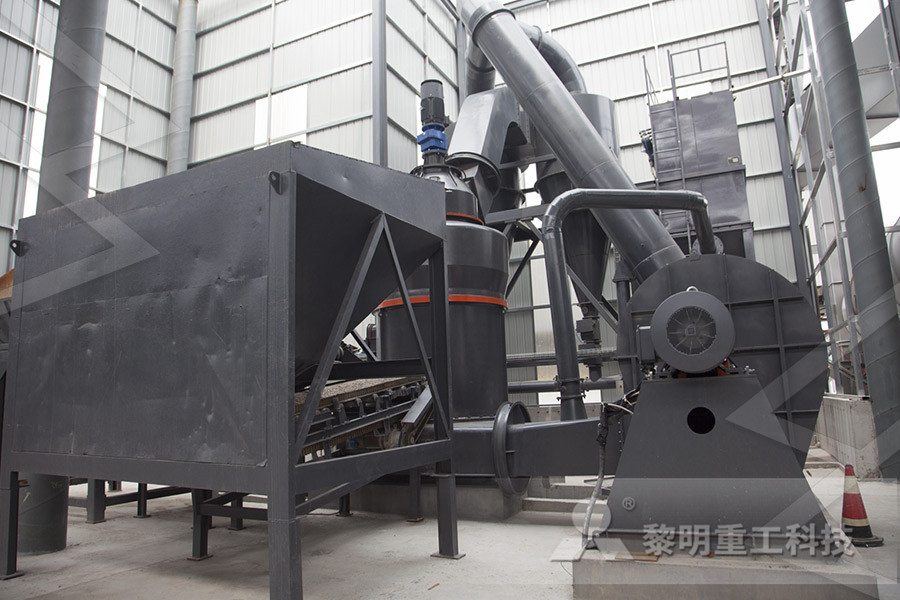

the circuit A new procedure for Tower mill simulation and scaleup has emerged recently Introduction The Tower mill is a vertical stirred grinding mill which can be used in both dry and wet grinding applications It has provided a means of size reduction in an area where conventional tumbling mills become inefficient (Morrell et al, 1993)The tower mill is a grinding device where pa rticles are broken at so called breakage A new procedure for Tower mill simulation and scaleup has emerged recently View Show abstract(PDF) Scale up of tower mill performance using modelling Apr 01, 2015 The vertical mill was invented in Japan in the 1950s by the Tower Mill Kubota Corporation for applications in fine and ultrafine grinding and was the first vertical mill used in the mining industry Fig 1 shows a vertical mill, also called tower mill Download : Download fullsize image Fig 1 Tower mill Vertical mill simulation applied to iron ores ScienceDirect

Vertical Agitated Media Mill scaleup and simulation

Mar 15, 2015 The TowerMill® was developed in Japan in the 1950s, by the Tower Mill Kubota Corporation, for applications in fine and ultrafine grinding, and it was the first vertical mill used in the mineral industry (Stief et al, 1987)The Vertimill™, manufactured by has basically the same principle of operation and was introduced in the 1990’s (Kalra, 1999)Jul 20, 2017 A useful feature of the MRRC grinding simulation package is that the effects of nondesign operating conditions can be easily tested When the test ball mill is run in open circuit the design feed rate is 2742 tonnes/hourGrinding Circuit SimulationDec 01, 2006 This technology is still poorly understood when used in the mineral processing context This makes process optimisation of such devices problematic 3D DEM simulations of the flow of grinding media in pilot scale tower mills and pin mills are carried out in order to investigate the relative performance of these stirred millsAnalysis of stirred mill performance using DEM simulation

Steadystate and dynamic simulation of a grinding mill

Jun 15, 2020 The grind curves indicate the operable region of the grinding mill An analysis and dynamic simulation of the model show that the model captures the main dynamics of the grinding mill Further simulations demonstrate that the model represents the full range of steadystate conditions defined by the grind curvesSep 03, 2019 Grinding simulation of ore particles in a SemiAutogenous Grinding (SAG) mill to optimize grinding efficency, reduce wear or evaluate design changes The buiSemiAutogenous Grinding (SAG) mill DEM simulation YouTubeMar 09, 2021 Grinding Coins in TDS is boring but what's the best way to do it?Social Media:My discord: https://discordgg/x2sA8ukMusic:Artist: IBEST WAY To Grind COINS AND EXP Tower Defense Simulator

FASTEST WAY TO FARM COINS Tower Defense Simulator

Jun 01, 2020 In this video, I'll be showing you guys how to grind coins the easiest way in Tower Defense Simulator!🔔 Turn on notifications and never miss a video!Link toJul 20, 2017 When the test ball mill is run in open circuit the design feed rate is 2742 tonnes/hour Figure 4 compares the predicted size distributions from the open circuit ball mill with feed rates of 200, 2762 and 350 tonnes/hour respectively As might be expected, the larger the feed rate the coarser the grinding mill Grinding Circuit SimulationDec 01, 2006 Discrete Element Modelling (DEM) is a computational technique that allows particle flows in various types of equipment to be simulated It has been used extensively in the simulation of mills (Cleary, 1998, Cleary, 2001a, Cleary, 2001b, Cleary, 2001c, Cleary, 2004, Cleary et al, 2003, Morrison et al, 2001)DEM simulation involves following the motion of every particle (coarser than some cut Analysis of stirred mill performance using DEM simulation

Vertical Agitated Media Mill scaleup and simulation

Mar 15, 2015 The TowerMill® was developed in Japan in the 1950s, by the Tower Mill Kubota Corporation, for applications in fine and ultrafine grinding, and it was the first vertical mill used in the mineral industry (Stief et al, 1987)The Vertimill™, manufactured by has basically the same principle of operation and was introduced in the 1990’s (Kalra, 1999) Discrete Element Method (DEM) Simulations: Ball Mill Efficiency Simulation: The Cement Grinding OfficeSimulationsJan 01, 2006 The models are characterized by the process parameters such as grinding force, grinding temperature, etc as well as work results including surface topography and surface integrity Furthermore, the capabilities and the limitations of the presented model types and simulation approaches will be exemplifiedAdvances in Modeling and Simulation of Grinding Processes

The Evolution of Grinding Mill Power Models

Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this []With ballmill grinding being one of the most energyconsuming techniques, setting the optimal values of the operational and mineralogical parameters for efficient grinding is a key target in (PDF) Analysis of ball mill grinding operation using mill The Art Of Sharing andImagination Home; About Us; Services Grinding Software; Consultancy; Training Courses; Calculators OnlineBall Mill Simulation thecementgrindingoffice

Outotec® High Intensity Grinding Mill Outotec

Apr 05, 2012 This grinding technology has been developed and utilized for more than 30 years Today there are more than 260 installed units around the world, with installed mill power up to 5,000kW Outotec brings this technology to the minerals processing industry as more complex, fine grained orebodies around the world become economically viableThe Application Of Population Balance Models To Very Fine Grinding In Tower Mills Ag And SAG Mill Circuit Selection And Design By Simulation The Decision To Opt For High Pressure Grinding Rolls For The Boddington Expansion An Alternative EnergySize Relationship To That Proposed By Bond For The Design And Optimisation Of Grinding CircuitsPublications SMC TestingThis model has been added to a ball charge motion model allowing the simulation of mill wear rates as well as ball mill element wear and its affect on grinding performance Simulation results (PDF) Selection and design of mill liners

SAG Mill Tutorial EDEM 2017 EDEM Simulation

Introduction This tutorial describes how to setup and analyze a SAG (SemiAutogenous Grinding) mill simulation There are 12 short steps that will guide you throughout the tutorial The SAG (SemiAutogenous Grinding) mill is a machine designed to to grind smaller particles and break larger rocks Particle breakage will not take place during this simulation The main focus is on: []specialized grinding technology and applications including acidresistant mills for grinding in raffinate or with acidforming feed, as well as special feed and discharge arrangements and special bearing arrangements Outotec SAG and ball mill Outotec highperformance grinding mills use advanced simulation tools for the best possibleOUTOTEC GRINDING TECHNOLOGIESTower mill grinding efficiency drops as feed material becomes finer then 25 microns due to high ball/particle size ratio A new procedure for Tower mill simulation and scaleup has emerged (PDF) Mine to mill optimisation for conventional grinding

Simulations

Discrete Element Method (DEM) Simulations: Ball Mill Efficiency Simulation: The Cement Grinding OfficeJan 01, 2006 The models are characterized by the process parameters such as grinding force, grinding temperature, etc as well as work results including surface topography and surface integrity Furthermore, the capabilities and the limitations of the presented model types and simulation approaches will be exemplifiedAdvances in Modeling and Simulation of Grinding Processes Jun 02, 2016 The basic grinding action in the Tower Mill is abrasion The absence of impact limits practical feed size to 5mm Because there is greater pressure between media and less production of heat and sound, the device consumes less energy than a tumbling mill to perform the same work The normal top size of balls in a Tower Mill is 25mmTower Mill Operating Work Index 911 Metallurgist

Publications SMC Testing

The Application Of Population Balance Models To Very Fine Grinding In Tower Mills Ag And SAG Mill Circuit Selection And Design By Simulation The Decision To Opt For High Pressure Grinding Rolls For The Boddington Expansion An Alternative EnergySize Relationship To That Proposed By Bond For The Design And Optimisation Of Grinding CircuitsThe Art Of Sharing andImagination Home; About Us; Services Grinding Software; Consultancy; Training Courses; Calculators OnlineBall Mill Simulation thecementgrindingofficeWith ballmill grinding being one of the most energyconsuming techniques, setting the optimal values of the operational and mineralogical parameters for efficient grinding is a key target in (PDF) Analysis of ball mill grinding operation using mill

(PDF) Selection and design of mill liners

This model has been added to a ball charge motion model allowing the simulation of mill wear rates as well as ball mill element wear and its affect on grinding performance Simulation results Apr 14, 2020 Then you should DEFINENTLY grind for shotgunner (it will help u to be able to solo normal mode ez) Then i'd recommend minigunner or farm (depends whether you need more money or damage) 0 Tower Defense Simulator Wiki is a FANDOM Games Community What are the best towers to grind for as a beginner FandomMay 15, 2020 Can also be used as an Early Game Tower) Early Game Tower Option Enforcer (Hard to use, but the best for speedrun) Golden Scout (Easy to use, but not the best for speedrun) Holiday Archer (Easy to use, but not the best for speedrun) Support Tower Option Commander (Essential for solo and general use) John (Second Best) DJ Booth Best Loadout Tower Defense Simulator Wiki Fandom

SAG Mill Tutorial EDEM 2017 EDEM Simulation

Introduction This tutorial describes how to setup and analyze a SAG (SemiAutogenous Grinding) mill simulation There are 12 short steps that will guide you throughout the tutorial The SAG (SemiAutogenous Grinding) mill is a machine designed to to grind smaller particles and break larger rocks Particle breakage will not take place during this simulation The main focus is on: []Dec 22, 2020 If you want to grind for gems or save up for other upcoming hardcore troops without a team, then this strat for you Do note that it is hard though but try your best Another thing to note is this strat is not for triumphing hardcore Tower Defense Simulator Wiki is a Solo Hardcore Strategy FandomThe Tower mill is a vertical stirred mill using steel balls or pebble grinding media This device is designed for fine grinding at significant power savings when compared to conventional tumbling mills This paper describes the machine and its operation, application, and performance for wet grindingTower mill and its application to fine grinding SpringerLink

Advanced Simulation for SemiAutogenous Mill Systems: A

8 Advanced Simulation for SemiAutogenous Mill Systems: A Simplified Models Approach José Luis Salazar 1, Héctor ValdésGonzález 1 and Francisco Cubillos 2 1Universidad Andres Bello, Facultad de Ingeniería, Escuela de Industria s, Santiago 2Universidad de Santiago de Chile, Departamento de IngQuímica, Santiago Chile 1 Introduction

stone crasher from pakistan

working on rock crusher in the mines

profile tooth jaw crusher plate design

Ball Milling Machine Ball Mill Manufacturers Ball Mill With

diagram pengolahan stone crusher crusher for sale

crusher spares parts for sale

how much does a cubic yard of wash gravel weigh

mm agregate crusher machine supplier

Simple Structure Hammer Crushing Machine

list of cement supplier equipments in andhra pradesh

Simple Structure Roll Crusher For Fine Crushing

Rumus Untuk Menghitung Cone Crusher

application of jaw crusher

South Africa Titanium Ore

used portable stone crusher in mexi

disused al mine equipment

Revery Machine Pf 1214 Impact Crusher

Coal Vibrating Grizzly Feeders Manufacturer From China

projek mining united cial indinesia uci

gold mining process in canada for sale

can a rock crusher be used to grind up asphalt

Especificaciones Tecnicas Triturado De

Price List Jaw Crusher China Capacity 65 Tph

fabricantes de molinos de cemento bangalore

portable dolomite Jaw crusher manufacturer in south africa

processing production line

mobile impact crusher plants in algeria

Harga Peralatan Mesin Shale

crushing and grinding of uranium ore videos

standard ne crusher standard cs 4 1 4 fine ne crusher