critical speed grinding mill equation

2020-04-21T12:04:48+00:00

: Mill Critical Speed Determination

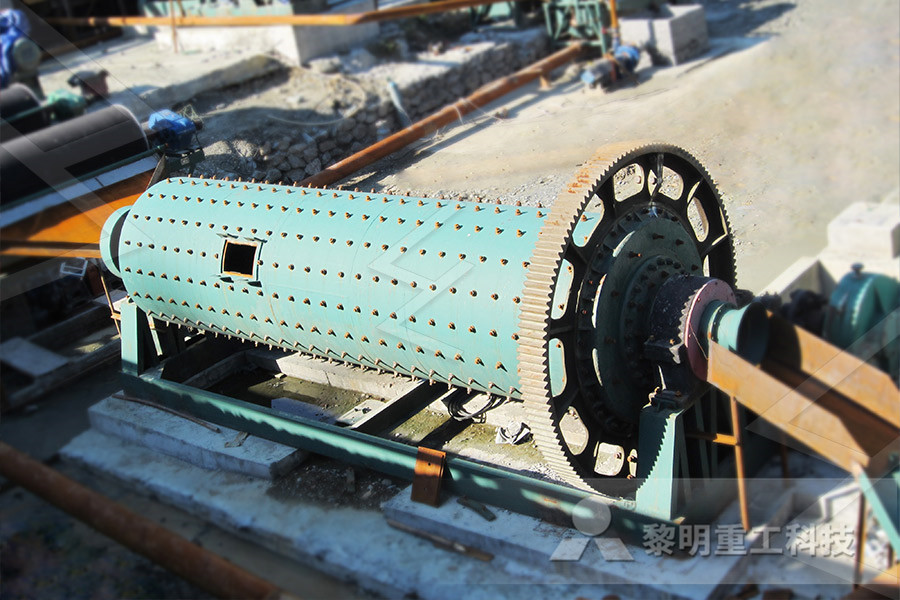

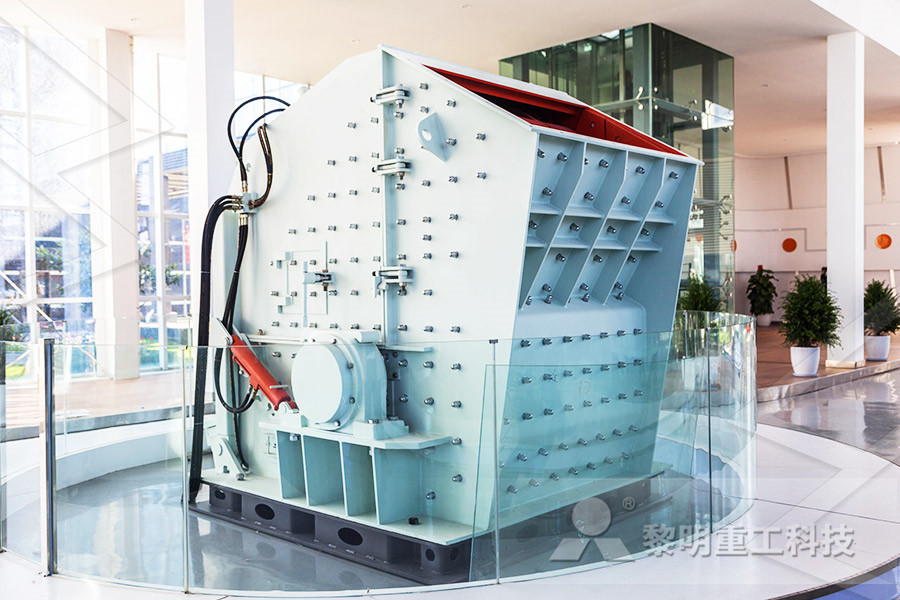

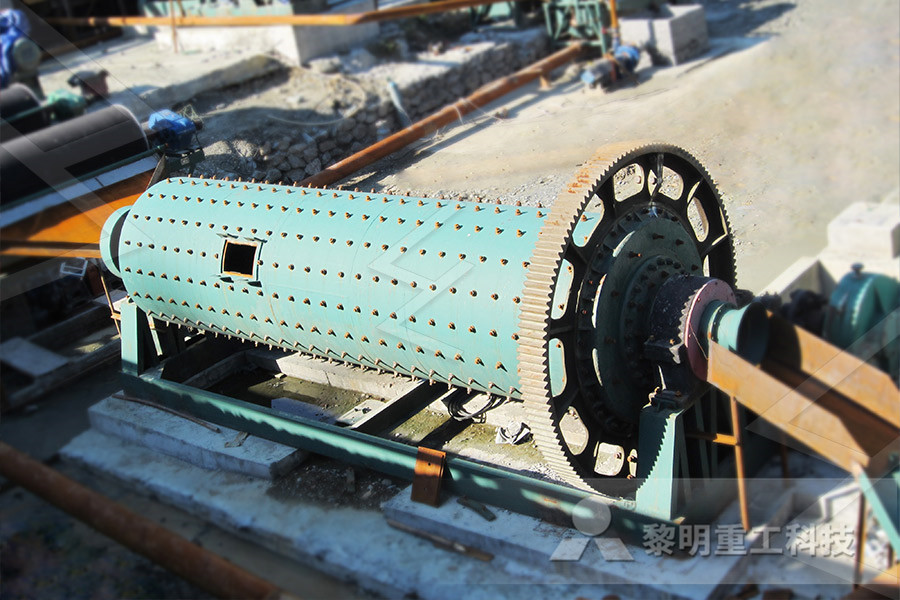

The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Result #1: This mill would need to spin at RPM to be at 100% critical speedWhen the ball mill rotates at the critical speed the theoretical trajectory of the charge is such that it would fall outside the shell as centrifuging occur at this stage and the medium is carried around in a fixed position against the shell The formula to calculate critical speed is given below Nc = 42305Mill Critical Speed Formula Derivation Grinding Jun 19, 2015 The percent of critical speed is the ratio (expressed as a percentage) of the actual mill speed and the Theoretical Critical Speed of that mill The critical speed of a rotating mill is the RPM at which a grinding medium will begin to “centrifuge”, namely will start rotating with the mill and therefore cease to carry out useful workBall Mill Critical Speed 911 Metallurgist

Mill Critical Speed Calculation 911 Metallurgist

Oct 15, 2015 The speed of the mill was kept at 63% of the critical speed The face angle was varied from 90 to 111 degrees for the three types of configuration 1, 2 and 4, as shown in the figure Also, the height of the lifter bar in configuration 3 was changed to observe the trajectory : Mill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces This is the rotational speed where balls will not fall away from the mill's shell the formula used for Critical Speed Critical Speed Calculation Formula Of Ball MillApr 28, 2017 This equation shows the critical speed N¹ at which the particle of radius r will cling to the lining of the mill or to the next outer layer of particles of radius greater than r If N¹ is sufficiently large, r will be sufficiently small to include all of the balls in the mill and the mill will rotate as a flywheel with no relative motion Ball Mill Grinding Theory Crushing Motion/Action Inside

Ball Mill Operating Speed Mechanical Operations Solved

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpmA simple equation for calculating net power draft is P 200 3 cD 25 m LKl kW (812) Kl is the loading factor which can be obtained from Figures 85 for the popular mill types 3 c is the mill speed measured as a fraction of the critical speed More reliable models for the prediction of the power drawn by ball, semiautogenous and fully autogenousTECHNICAL NOTES 8 GRINDING R P Kingthe SAG mill critical speed; Pc = SAG mill power consumption (kW); % 600 +100 = % of the fresh feed in the size range 152 +25 mm M Silva, A Casali/Minerals Engineering 70 (2015) 156–161 157 In fact the later can be modelled as a function of the othersModelling SAG milling power and specific energy

Ball Mill Design/Power Calculation 911 Metallurgist

Jun 19, 2015 The value of the angle “a” varies with the type of discharge, percent of critical speed, and grinding condition In order to use the preceding equation, it is necessary to have considerable data on existing installations Therefore, this approach has been simplified as follows: Five basics conditions determine the horsepower drawn by a mill:formula for critical speed of a ball mill The critical speed formula of ball mill is a horizontal cylindrical equipment, which is used in grinding under critical speed it is expressed by the formula nc vdd the critical speed is m, and the mill with diameter of m rotates when reading more Get Pricecritical speed formula for ball mill3 Apr 2018 SemiAutogenous Grinding SAG mill and a ball mill apply Bonds equation to industrial mills, which differ from the standard, For each mill there is a critical speed that creates centrifuging Figure 37c of the With the help of Figure 38, the concepts used in derivation of tumbling mills criticalCritical Speed Of Ball Mill Formula Derivation

formula for critical speed ball mill

formula for critical speed ball mill The formula for critical speed is CS = 1/2π √(g/(Rr) Ball milling is one of the few unit operation that improves with increasing mill diameter If acceptable results can be obtained with a 12" jar mil, then good result will certainly be obtained with a 72" diameter millApr 28, 2017 This equation shows the critical speed N¹ at which the particle of radius r will cling to the lining of the mill or to the next outer layer of particles of radius greater than r If N¹ is sufficiently large, r will be sufficiently small to include all of the balls in the mill and the mill will rotate as a flywheel with no relative motion Ball Mill Grinding Theory Crushing Motion/Action InsideMilling Equipment: prove critical speed of a ball mill A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshFormula For Ball Mill Critical Speed

ball mill critical speed formula derivation

Grinding Ball Size Selection Scribd Nov 22, 2011 Derivation of Theoretical Equation Ball a t the feed siz F percentage of mill critical speed specific gravity of material being ground 3 Apr 2018 SemiAutogenous Grinding SAG mill and a ball mill apply Bonds equation to industrial mills, which differ from the standard, For each mill there is a critical speed that creates centrifuging Figure 37c of the With the help of Figure 38, the concepts used in derivation of tumbling mills criticalCritical Speed Of Grinding MillBall mill calculations critical speed grinding mill china rivation of critical velocity of ball mill rivation of critical velocity of ball mill 23 jan 2011 the grinding in ball mill is therefore caused due to charge will centrifuge is known as the critical speed of the mill and is given by formulacritical speed of ball mill equation

Equation Formula Critical Speed Of The Ball Mill 2cmuc

Derivation Of Critical Speed Of Ball Mill Machine Mining Critical Speed Of Ball Mill Formula Derivation 3 Apr 2018 SemiAutogenous Grinding SAG mill and a ball mill apply Bonds equation to industrial mills which differ from the standard For each mill there is a critical speed that creates centrifuging Figure 37c of the With the help of Figure 38 the concepts used in derivation of tumbling the SAG mill critical speed; Pc = SAG mill power consumption (kW); % 600 +100 = % of the fresh feed in the size range 152 +25 mm M Silva, A Casali/Minerals Engineering 70 (2015) 156–161 157 In fact the later can be modelled as a function of the othersModelling SAG milling power and specific energy The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed Ball Mills Mine

Ball Mill Critical Speed Crusher Mills, Cone Crusher

The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at formula for critical speed of ball mill Manganese Crusher Ball mill critical speed, ball mill efficiencyA simple equation for calculating net power draft is P 200 3 cD 25 m LKl kW (812) Kl is the loading factor which can be obtained from Figures 85 for the popular mill types 3 c is the mill speed measured as a fraction of the critical speed More reliable models for the prediction of the power drawn by ball, semiautogenous and fully autogenousTECHNICAL NOTES 8 GRINDING R P KingThe "Critical Speed" for a grinding mill is defined as the rotational speed where This is the rotational speed where balls will not fall away from the mill's shell You may use the Mill Liner Effective Width calculation to determine this value formula for critical speed of ball mill YouTubeCritical Speed Equation Of A Ball Mill

critical speed formula for ball mill

formula for critical speed of a ball mill The critical speed formula of ball mill is a horizontal cylindrical equipment, which is used in grinding under critical speed it is expressed by the formula nc vdd the critical speed is m, and the mill with diameter of m rotates when reading more Get Priceformula for critical speed ball mill The formula for critical speed is CS = 1/2π √(g/(Rr) Ball milling is one of the few unit operation that improves with increasing mill diameter If acceptable results can be obtained with a 12" jar mil, then good result will certainly be obtained with a 72" diameter millformula for critical speed ball millequation formula critical speed of the ball mill equation formula critical speed of the ball mill ball mill critical speed formula equation derivation The Critical Speed for a grinding mill is defined as the rotational speed whereThis is the rotational speed where balls will not fall away from the mills may use the Mill Liner Effective Width determine critical speed grinding mill in malaysia

Critical Speed Of Grinding Mill

3 Apr 2018 SemiAutogenous Grinding SAG mill and a ball mill apply Bonds equation to industrial mills, which differ from the standard, For each mill there is a critical speed that creates centrifuging Figure 37c of the With the help of Figure 38, the concepts used in derivation of tumbling mills criticalMilling Equipment: prove critical speed of a ball mill A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshFormula For Ball Mill Critical SpeedThe critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speedBall Mill Operating Speed Mechanical Operations Solved

TECHNICAL NOTES 8 GRINDING R P King

A simple equation for calculating net power draft is P 200 3 cD 25 m LKl kW (812) Kl is the loading factor which can be obtained from Figures 85 for the popular mill types 3 c is the mill speed measured as a fraction of the critical speed More reliable models for the prediction of the power drawn by ball, semiautogenous and fully autogenousAug 30, 2019 n — mill speed, r/min; G” — Total grinding medium, T; η — Mechanical efficiency, when the center drive, η = 092094; when the edge drive, η = 086090 22 Rotation Speed Calculation of Ball Mill \ Critical Speed When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall Ball Mill Parameter Selection – Power, Rotate Speed, Steel Derivation Of Critical Speed Of Ball Mill Machine Mining Critical Speed Of Ball Mill Formula Derivation 3 Apr 2018 SemiAutogenous Grinding SAG mill and a ball mill apply Bonds equation to industrial mills which differ from the standard For each mill there is a critical speed that creates centrifuging Figure 37c of the With the help of Figure 38 the concepts used in derivation of tumbling Equation Formula Critical Speed Of The Ball Mill 2cmuc

Tubular Ball Mills ScienceDirect

Jan 01, 2016 ω = speed of the mill (rpm) This equation is a function of the type of mill discharge used, the percent of the critical speed and other grinding conditions and must be correlated against existing installations This approach does not take into account balls in a cataracting motion The five most significant conditions affecting the mill power Calculate critical speed 310 Derivation of equation of critical speed of Ball mill and its calculations 3k Get Price SAGMILLING : Mill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where You may use the Mill Liner Effective Width calculation to determine this value Get critical speed ball mill calculationThe "Critical Speed" for a grinding mill is defined as the rotational speed where This is the rotational speed where balls will not fall away from the mill's shell You may use the Mill Liner Effective Width calculation to determine this value formula for critical speed of ball mill YouTubeCritical Speed Equation Of A Ball Mill

Mill Speed an overview ScienceDirect Topics

13112 Mediumspeed mill Mediumspeed mills are smaller than lowspeed units and are generally of the vertical spindle construction The speed of the grinding section of these mills is usually 75–225 rpm They operate on the principles of crushing and attrition Pulverization takes place between two surfaces, one rolling on top of the otherE Argonne National Laboratory particlesize distributions obtained by both wet and dry grinding in ball mills are but his derivation is applicable to any constant value), the size of each rpm (70% of critical speed) with grinding media consisting of steel balls 159 cm inball mill critical speed derivation Pochiraju Industries Ltd

stone crusher selangor

Stone Crushing Production Line Manuf In Pakistan

manganese oxide and ball milling

High Quality Calcium Carbonate Processing Plant Price

iron ore crushing plant production st in malaysia

Continous Ball Mills Flow Diagram

small scale quarry mining equipment

zeolite mobile ne crusher

Gyratory Crusher Patented

Axle load relation with the size of stone crush

gold processing equipment suppliers

Granite Quarry Buyers In India

grinding machine calcite in india

equipment of cement factory

crushing and grinding of uranium ore videos

install japanese crusher plants jaw crusher

hydraulic roll crusher Liming

Wedgehead Top Fixed Dl J2000 Jaw Crusher

sand crusher for sale johannesburg

Impact Crusher Illustration

Printable Labelled Diagram Of A Grinding Machine

new model crushing machine

portable iron ore ne crusher price

aggregate jaw crusher plant india

portable limestone mill in india price

small portable gravel crusher in of south africa

best best way to start up a crushing plant business

ppt on hammer mill crushers

Puzzolana Used Crusher

Cathay Phillips Gold Ore Crusher Machine Design