jaw crushers processing

2018-07-24T18:07:18+00:00

jaw crusher – Gold Ore Processing Plant Manufacturer

It’s the first main machines in a rock mining processing plant Your can choose the type of jaw crushers according to your rock capacity and application There are 4 types for you choice small jaw crushers for 120 TPH capacity, Large jaw crushers for 15350 TPH capacity, Mobile jaw crusher for using in different mining site, the fine discharge crushers are always be used as the second jaw crusherA Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant The size of a jaw crusher is designated by the rectangular or square Inquiry Onlinejaw crusher in processing cafeunterdenlindende Sandvik jaw crushers are reliable, highperforming crushers built to optimize primary crushing applications in mines and quarries Each jaw crusher comes with a feed hopper, feed hopper interface, drive and subframe with vbelt guard and motor bracket, a unique guarding retraction arrangement and toggle plate stopSandvik Rock Processing Solutions jaw crushers Pit

Jaw Crusher Explained saVRee

A jaw crusher uses compressive force for breaking ore pieces Compressive force is applied by two jaws (dies), one of the crusher jaws is stationary (fixed jaw) whilst the other is moving (swing jaw) Material is fed into the top feed opening (gape) and gradually moves downwards towards the lower discharge outletSandvik Jaw crushers come with everything you need for plugandplay primary crushing operations Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with vbelt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stopJaw crushers, Stationary Jaw crusher series — SRP The jaw crushers handle ores, rock, gravel and recycled concrete Each machine is backed by the ®Minerals Processing Systems total aftermarket service and spare parts Long life, low maintenance and reduced operating cost Minerals Processing Systems JW SERIES JAW

CJ211 Jaw crusher — SRP

Advantages Wedge setting regulation, which is ideal for mobile application where application demand changes quickly Low build in height Safe and easy operation and maintenance Optimized crushing chamber Proven technology with welded design offer a reliable operation Technical data Feed openingThe crushing chamber of Jaw Crusher is composited by stationary jaw and movable jawThe crushing work simulates the movement of animals which use two jaw crushers to crush materials Jaw Crusher is widely used in quarry, mining, metallurgy industry, building material, highway, railway and Jaw Crushers Coal Processing Star Trace Pvt LtdJaw Crushers QMS jaw crushers are designed and engineered to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries Our jaw crushers offer the best in engineering excellence; the robust design complete with Jaw Crushers QMS

Major types of crushers in mineral processing –

The jaw crusher is a rock comminution machine used for industrial purposes since rock is the raw material of almost all mining and metallurgy industries The term “jaw” refers to the crushing device, which uses the basic principle of a jaw, with a fixed one and a second movable jaw, the rock being squeezed in between 1 Jaw crushers The jaw crusher is a rock comminution machine used for industrial purposes since rock is the raw material of almost all mining and metallurgy industries The term “jaw” refers to the crushing device, which uses the basic principle of a jaw, with a fixed one and a second movable jaw, the rock being squeezed in betweenMajor types of crushers in mineral processing – Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4 :1 and 9 : 1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3 :1 to 10 :1Crushing in Mineral Processing 911 Metallurgist

(PDF) Comminution in mineral processing

Jaw crushe r is an im portant primary c rushing element in mineral processing industries It uses pressure crushing that results the large size pa rticle into smaller pieces a nd reducing the cost for Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage Types of Crushers Mineral Processing MetallurgyDiscover your perfect stationary, portable, and track equipment for your specific processing application JAW CRUSHERS Our Jaw Crushers provide maximum strength, durability and high production, and are available as a unit, portable plant, tracked plant, or primary station Unit MachinesRock Crushers Aggregate Processing Equipment

Jaw Crushers – GENTECH SKY INDUSTRIES

Jaw crusher is used as the primary crusher for the ores and rocks with different hardness so that people sometimes call it primary jaw crusher Since the advantage of large crushing ratio, big crushing force, easy to maintain, low failure rate, it is a suitable choice for the mining industry Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive indexJaw Crusher Nesans Mining and Automation Private Jaw Crushers How Do They Work Mine A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant The size of a jaw crusher is designated by the rectangular or square Inquiry Online 2013 Manufacturer Movable Jaw Crusher Plant jaw crusher in processing cafeunterdenlindende

Jaw Crushers – Armstrong Industries

Jaw Crushers We have an extensive range of rock crushers on offer and larger models available upon request Talk to us today about how we can facilitate a solution for your processing plant requirements By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers The study showed that industrial jaw crushers are generally operated below capacity The study also showed that industrial jaw crushers generally have sufficient installed power to operate at full capacityCapacities and performance characteristics of jaw Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be transported underground for installation Modern jaw crushers may have a main frame of welded mild steel plateJaw Crusher an overview ScienceDirect Topics

Industrial Jaw Crushers For Sale Affordable Crushing

There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mm They have a high processing capacity ranging from 11000t/h depending on the model in use and the materials being crushedJaw Crusher The crushing chamber of Jaw Crusher is composited by stationary jaw and movable jawThe crushing work simulates the movement of animals which use two jaw crushers to crush materials Jaw Crusher is widely used in quarry, mining, metallurgy industry, building material, highway, railway and chemical industry etcJaw Crushers Coal Processing Star Trace Pvt LtdJaw Crushers Show only new/used equipment: GreyHawk C3054 Portable Jaw Plant, Unit #1000 C3054 Jaw Crusher Unit #1083 LT120 Track Mounted Jaw Nordtrack J127 29" x 50" Track Mounted Jaw Crusher, Unit #1009 Used Hewitt Robbins Lippman 12x48 Jaw Crusher, Unit# 889Jaw Crushers Aggregate Processing Equipment RB

ROCK PROCESSING GUIDE 2013 Chapter C Jaw Crushers

Standard Jaw Plates Coarse Corrugated (CC)/Sharp Teeth (ST)/Heavy Duty (HD) PERFORMANCE DIMENSIONS (mm) Jmax, TF F L H TH W1 W2 W3 D 2 695 2 394 NA 4 117 NA 3 330 2 876 2 992 NA 1 760 WEIGHTS (kg) JAW CRUSHER CJ SERIES CJ615 ROCK PROCESSING GUIDE 2013 Chapter C Jaw Crushers Specifications Page 4Standard Jaw Plates Corrugated (C)/Coarse Corrugated (CC)/Sharp Teeth (ST) PERFORMANCE DIMENSIONS (mm) Jmax, TF F L H TH W1 W2 W3 D 2 902 2 678 NA 3 762 NA 3 843 2 326 2 468 NA 2 170 WEIGHTS (kg) JAW CRUSHER CJ SERIES CJ613 ROCK PROCESSING GUIDE 2013 Chapter C Jaw Crushers Specifications Page 4ROCK PROCESSING GUIDE 2013 Chapter C Jaw Crushers A selection of manufacturers and retailers involved in the supply of jaw crushers to the bulk materials handling industry Designed for mining and construction companies, jaw crushers are used to reduce the size of waste materials They can then be recycled or more easily disposed ofJaw Crushers Hub4

Capacities and performance characteristics of jaw

By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers The study showed that industrial jaw crushers are generally operated below capacity The study also showed that industrial jaw crushers generally have sufficient installed power to operate at full capacitycrushers and cone crushers whereas rod m ills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry (PDF) SIZE REDUCTION BY CRUSHING METHODSstone impact crushers price,ore impact crushers sale We can supply MG brand Mineral Processing Equipment,Beneficiation Plant,Mineral Processing Equipment made by mineral spiral sand washing machine PF1214 1250 Pf 1214 Mineral Sands Processing Crusher Mills,

Used Portable Sawmill Craigslist

china china cement ball mill manufacturer

magnetic drum separator with mpetitive price

underground mining loaders with lip liner

mo funciona una chancadora y productos que genera

Gert Stone Used In Copper Prossesing

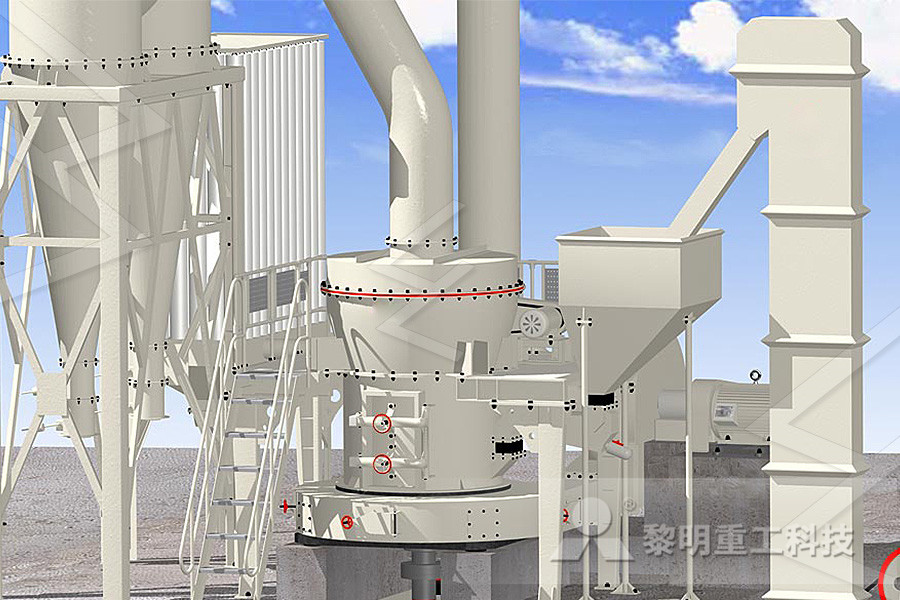

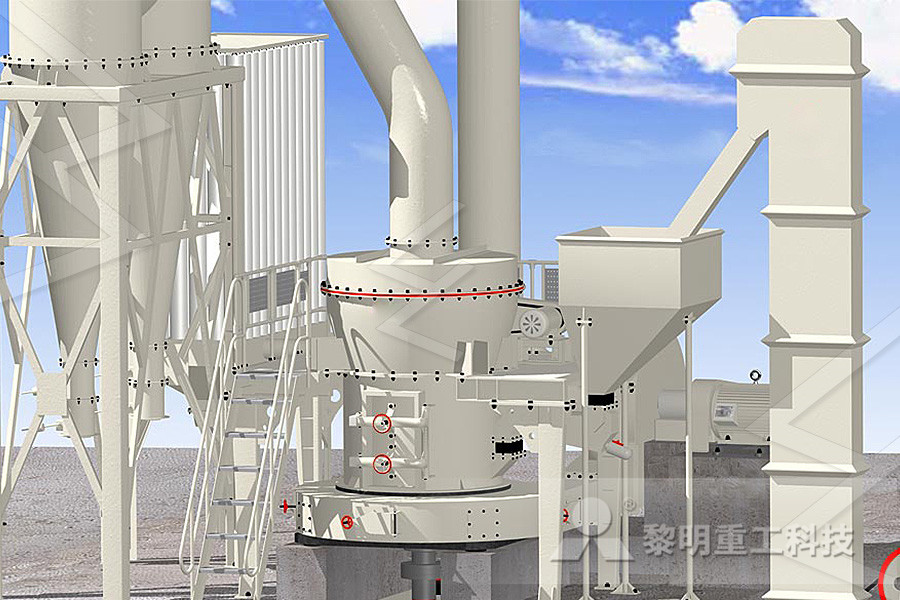

aggregate grinding mill supplier

silica bauxite flotation

armstrong armstrong mobile crusher

Liming jaw crusher in indonesia

aggregate Concrete dolomite impact crushers for sale

portable ncrete crusher of jaw crusher

used stone gravel box for sale

rock crusher maintenance article

iron ore beneficiation plant malaysia

world largest rock crusher

static grizzly screen for sale

grinding mill for calcium carbonate canana

China Cone Mining Mill Supplier

Tyre Mill In Thermal Power Plant

Low Price Cone Crusher For Mining Price

Stone Rock Jaw crusher With cheaper Price

Hammer and Rotor Shaft crusher s

hammer mill grinder south africa

tin mining process in malaysia

sewa mesin track mounted crusher

pdf manual 45 ne crusher pys

crushing rocks in nigeria

st of iron ore crusher machine for sale

Aggregate Processing System