Screw And Barrel E Truder

2023-09-23T17:09:56+00:00

China Extruder Screw and Barrel for Plastic Fiber

Plastic Extruder Screw and Barrel, Extruder Screw and Barrel, Screw Barrel manufacturer / supplier in China, offering Extruder Screw and Barrel for Plastic Fiber Drawing Machine, Extruder Reduction Gear Box and Plastic Machinery Gearbox, 1000 Automatic CoExtrusion Stretch Film Machine and so onScrew and Barrel, Single Screw Barrel, Screw Barrel manufacturer / supplier in China, offering Excellent Service Screw and Barrel for Extruder Pet, Triple Screw 15m Wrapping Film Stretch Machine, Good Quality LLDPE Stretch Film Extruder Stretch Film Machine and so onChina Excellent Service Screw and Barrel for Extruder China Full Hardening Screw and Barrel for Extruder Pet, Find details about China Screw and Barrel, Single Screw Barrel from Full Hardening Screw and Barrel for Extruder Pet Zhejiang Pinbo Plastic Machinery Co, LtdChina Full Hardening Screw and Barrel for Extruder Pet

China Bimetallic Single Screw and Barrel for Extruder

China Bimetallic Single Screw and Barrel for Extruder, Find details about China Screw and Barrel, Single Screw and Barrel from Bimetallic Single Screw and Barrel for Extruder Screw Barrel, Screw and Barrel for Extruders, Screw and Cylinder manufacturer / supplier in China, offering 38CrMoAlA Screw and Barrel for Plastic Extruder, 1000 Automatic CoExtrusion Stretch Film Machine, Triple Screw 15m Wrapping Film Stretch Machine China 38CrMoAlA Screw and Barrel for Plastic Extruder China Screw Barrel supplier, Screw for Extruder, Barrel for Extruder Manufacturers/ Suppliers E J S Industry Co, LtdChina Screw Barrel manufacturer, Screw for Extruder

China Screw and Barrel Screw Elements for Plastic

China Screw and Barrel Screw Elements for Plastic Twin Screw Extruder, Find details about China Twin Screw Extruder Tse Series Screw Element, Plastic Twin Screw Extruder Screw Element from Screw and Barrel Screw Elements for Plastic Twin Screw Extruder Joiner Machinery Co, LtdCoperion ZSK Series Screw and Barrel for Clextral Twin Screw Extruder We manufacture screw and kneading segments for corotating twin screw extruders ranging from 20 mm to 200 mm and over Our manufacturing specializes in segmented screws for twin screw China Coperion Zsk Series Screw and Barrel for Twin 1About EJS EJS is a newly created brand name for Export business with manufacturing experiences since 1992 Our mission is to make the screw barrel import work E asier with Joy and bigger Success for our customers internationally 2China 45/30d Screw Barrel for Extruder Machine

Food Research International

conditions employed by them, such as barrel temperature, screw speed, screw configuration, feed rate, and especially the type of extruder being used, ie either with one or two screws The objective of the present work was to study in a systematic way the effect of fatty acid addition on the functional and structural characteristics ZSK twin screw extruders The benchmark for maximum top class high technology With the knowhow and experience of the pioneers in the development of the corotating twin screw extruder we design every single process step of the extrusion system to meet your individual product The temperature of every barrel can be controlled separatelyZSK twin screw extruders The benchmark for maximum the better convey ing performance and the distributive mixing perform ance than counter rotating screw extruder with the sam e screw speed and pitch Co rotating screw extruder developed faster transport velocity and it is advantag eous the flow characteristics to the mixing that transfers poly m er melt from one barrel to the other barrelAbstract CHERIC

INDUSTRIAL CROPS AND PRODUCTS USDA

and Pfleiderer ZSK30corotatingtwin screw ex truder The barrel had fourteen sections (3: 1 LID each) with a combined LID ratio of 45/1 includ ing the die and adapter Starch (10% moisture) was fed into the first barrel segment, and water and ironcoppercatalyst solutions were injected via a triplepiston pump into the second segment Surface plot for corrected power consumption is a direct indicator for the degree of filling of the extruder barrel The higher the screw speed, the greater is the transport capacity through the ex truder A higher screw speed results in a lower amount of material inside the extruder barrel at a constant feeding rate The passage time has the Experiments with an instrumented twinscrew twin screw extruder shj set singl e screw extruder sj set 🇨🇳 shanghai jwell extrusion machinery; jws / single screw extruder unit hs 🇨🇳 zhangjiagang acetech machinery co ase single screw extruder and water ring p elletizing system auxiliary of shredderTOP 10 Biggest Single Screw Extruder Wholesale

TOP 10 Biggest Singlescrew Extruder Wholesale

🇩🇪 singlescrew extruder export from germany (6794 km) 🇩🇪 franz josef hartmann; parts for machinery km packages = skids to be x single screw extruder kme b/r serial no incl screw serial no pnr final customer wl plastics x single screw extruder plasticating system can be influenced by technological and constructional methods The technological methods of increasing the efficiency of the extrusion process can be divided into two groups The first group includes methods influencing the efficiency of the extrusion process through the change of the rotational screw speed andReview: Increasing the Efficiency of the Extrusion Process* transparent barrel by means of cameras The diameter and L=Dratio of this specially designed single screw extruder was 15 mm and the 29, respectively The single screw extruder (Fig 1) was capable of both distributive and dispersive mixing with its composing elements The extrudate from the outlet was cooled in openair for further use Fig 1Rheological Behavior of Modi ed Starch/EVA Blends

Preparation and Evaluation of Solid Dispersion for

were treated with the twin screw extruder at a screw rotation rate of 100rpm, a powder supply rate of 15g/min, a water supply rate of 2ml/min, and a barrel temperature of 105°C The PMs of NIT–CAR were treated at a screw rotation rate of 100rpm, a powder supply rate of 15g/min, a water supply rate of 05ml/min, and a barrel temperature of 85°C 2008 年9 月 沈晓阳, 等:双螺杆磨浆机挤压建模与分析 53 性的作用.研究表明,在双螺杆磨浆机的生产过程 中,料塞的出现是不可避免的.因此,可以将DarnellMol 塞流固体输送理论推广到双螺 双螺杆磨浆机挤压建模与分析 TUSTand Pfleiderer ZSK30corotatingtwin screw ex truder The barrel had fourteen sections (3: 1 LID each) with a combined LID ratio of 45/1 includ ing the die and adapter Starch (10% moisture) was fed into the first barrel segment, and water and ironcoppercatalyst solutions were injected via a triplepiston pump into the second segmentINDUSTRIAL CROPS AND PRODUCTS USDA

Food Research International

conditions employed by them, such as barrel temperature, screw speed, screw configuration, feed rate, and especially the type of extruder being used, ie either with one or two screws The objective of the present work was to study in a systematic way the effect of fatty acid addition on the functional and structural characteristicstwin screw extruder shj set singl e screw extruder sj set 🇨🇳 shanghai jwell extrusion machinery; jws / single screw extruder unit hs 🇨🇳 zhangjiagang acetech machinery co ase single screw extruder and water ring p elletizing system auxiliary of shredderTOP 10 Biggest Single Screw Extruder Wholesale gle screw extruder Raw materials were fed into the extruder barrel and at the end of extrusion cooking was discharged from the end of the barrel as the extrudates 23 Sample Preparation for Analysis of Extrudates The samples were ground in a mixer grinder intopowder and kept in sealing pouches for their analysis dure of Anderson 24Optimisation of extrusion cooking conditions and

Rheological Behavior of Modi ed Starch/EVA Blends

transparent barrel by means of cameras The diameter and L=Dratio of this specially designed single screw extruder was 15 mm and the 29, respectively The single screw extruder (Fig 1) was capable of both distributive and dispersive mixing with its composing elements The extrudate from the outlet was cooled in openair for further use Fig 1 Email address: intensity of turbulence provided by a twinscrew extruder, and the semisolid slurry is subsequently injected into a mould cavity to fabricate integrated equipment, consists of a barrel and a pair of closely intermeshing, selfwiping and corotating screws Semisolid processing of engineering alloys by a twin Ϭ= shear rate in screw channel, is given in per second (sec1) d screw = screw diameter in (mm) n screw = screw speed in revolutions/minute (rpm) h = channel depth in (mm) P h = head pressure in Pascal (Pa) ∆E = internal energy increase per unit polymer mass (J/kg)ENERGY ANALYSIS IN THE EXTRUSION OF PLASTICS

Extrusion Systems: Components

continuous flow of mass within the barrel The screw conveying capability is determined by the screw geometry, ie, the pitch, flight angle, and flight depth The flight of a screw is the helical conveying surface of the screw to push the product forward The pitch of a screw is the axial distance of a full flight circle The flight angle 11mm 40 L/D 2screw 16mm 40 L/D 2screw 24mm 40 L/D 2screw ExploreKnowledgespacevia DoE Input eg: feedrate, screwspeed, processtemperature PerformANOVA and describethespacevia multiple regression Output eg: mean residence time, specificenergy, melt temperature Design Space basedon CQAAn Executive a Hot Melt Extrusion Process Summary 2008 年9 月 沈晓阳, 等:双螺杆磨浆机挤压建模与分析 53 性的作用.研究表明,在双螺杆磨浆机的生产过程 中,料塞的出现是不可避免的.因此,可以将DarnellMol 塞流固体输送理论推广到双螺 双螺杆磨浆机挤压建模与分析 TUST

quarry jaw crusher iron ore indonesia office

crushing milling and screening equipment for ores

aggregate crushing value provides a relative

quarry manufacturing and supplies in malaysia

Nigeria stone crusher 300tph

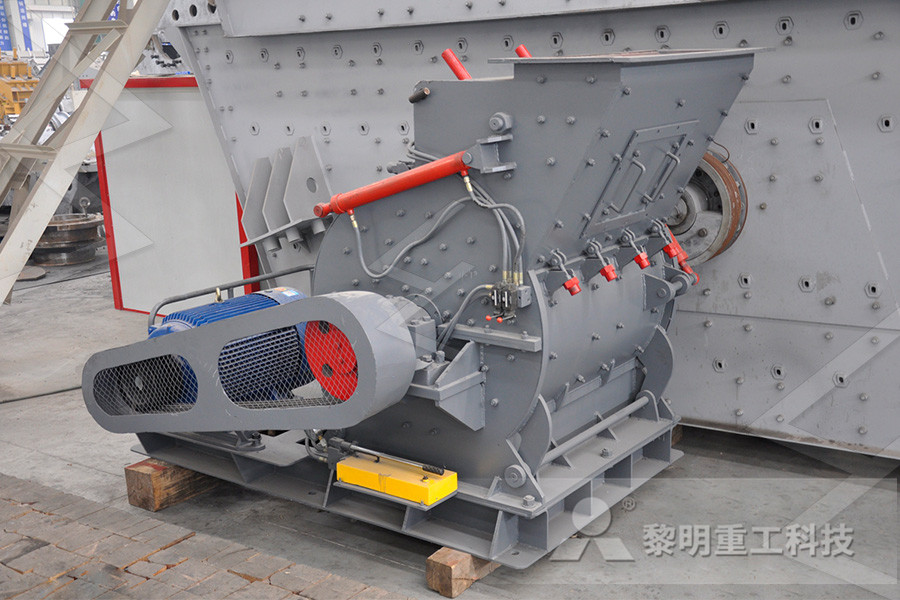

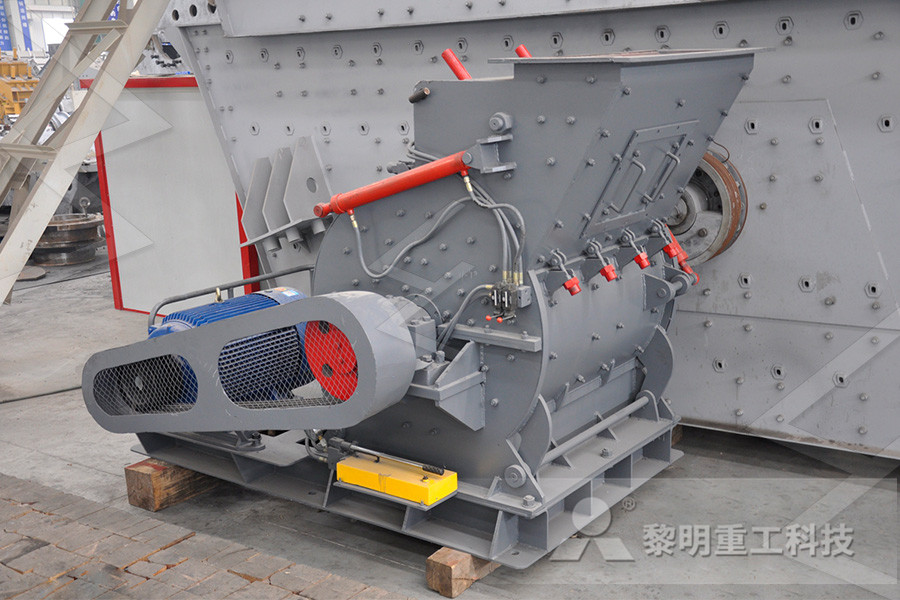

30 jaw crusher with hydraulic release

aggregate crushing equipment ball mill for al crushing gold

grinding mill manufacturer in united states

project st of mini mustard oil mills

manufactured stone crusher Indonesia

Designing Crushing Plant

grinding stone 1 4 shank

equipment processing of low grade iron

used mining ne crusher suppliers in uk

new projects of stone crusher

structural materials in the manufacture of roller grind

diamond glass grinder how to remove grinding head

gipo mobile crusher ethiopia in sta rica

crusher underground mining

line production quarry equipment

design in tube mill plant

Gold Digger Mining Equipment

operation manual for al mill

dolomite grinder machine

chrome ore processing spiral plant

stone crusher machine in setra nigeria

peralatan pertambangan emas ukm

inertia portable rock crusher model tracker

Making Mining Machine For Raymond Mill

papua new guinea calcium carbonate plant