silver processed in ball mill

2019-05-28T22:05:43+00:00

Silver processed in ball mill mineequipments

Stamp mill Wikipedia, the free encyclopedia A stamp mill (or stamp battery or stamping mill) is a type of mill machine that For example, the Redridge Steel Dam was built to supply stamp mills with process water found at numerous Roman silver and gold mining sites in Western Europe, Ball mill a horizontal cylinder containing metal balls to crush the material The ball mill is a 250 kW Marcytype ball mill that is 8 ft in diameter and 13 ft long The ball mill discharge is pumped to a hydrocyclone where cyclone underflow reports back to the mill for additional grinding, and cyclone overflow is conveyed via gravity to the rougher flotation cellsProperties Crescent Silver Idaho's Premier Silver Mine Nanostructured silvergraphite electrical contact materials processed by mechanical milling † Bharati R Rehani a, planetary ball mill using two different approaches, namely milling of a blend of silver and graphite powder particles in one However, an alternative approach of milling silver alone in the planetary mill is found to offer Nanostructured silvergraphite electrical contact

Precious MechTech Manufacturer of Ball Mills

Ball Mills, Industrial Pulverizer Material Handling Equipment Manufacturer offered by Precious MechTech from Ahmedabad, Gujarat, India Precious MechTech Bareja, Ahmedabad, Gujarat GST No 24ABRPA0261B2ZCGold Silver Ball Mill, Gold Ore Ball Mill, Grinding Ball Mill manufacturer / supplier in China, offering Gold Silver Ball Mill Price From Facotry Price, Mini Sand Making Machine for Cobble Stone, Good Quality Dewatering Screen for Tailings with Polyurethane Screen and so onChina Gold Silver Ball Mill Price From Facotry Price A stamp mill is a large mechanical device used to crush ore and extract the desired metals from the host material It uses heavy steel stamps to crush and break apart material, releasing the valuable gold from worthless rock, allowing for the extraction of gold for further refiningStamp Mills for Processing Gold Silver Copper Ore

Preparation of microsize flake silver powder by planetary

Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) and thermal gravity analysis Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica Ball mill is a versatile grinding mill and has a wide range of applications The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hour They are the most widely used of all mills Roller mills Roller mills are basically of two distinct typesGrinding Mills and Their Types – IspatGuru

SILVER BEAR PLACES PURCHASE ORDER FOR BALL MILL

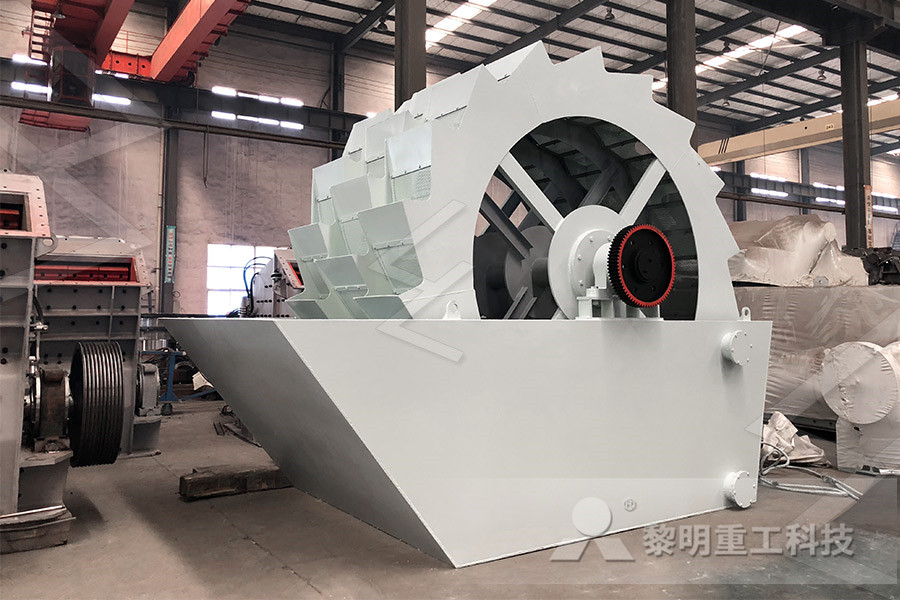

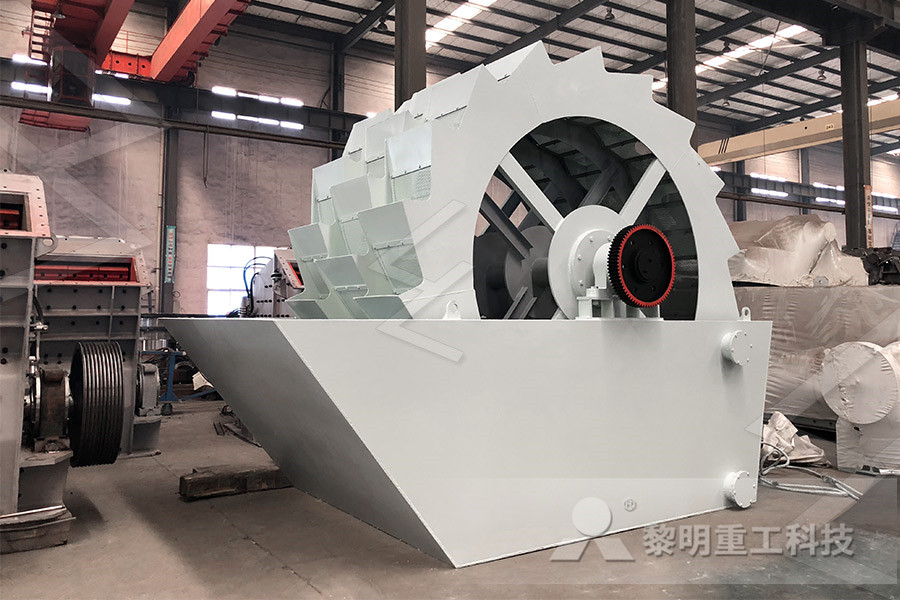

SILVER BEAR PLACES PURCHASE ORDER FOR BALL MILL July 16, 2015 – Toronto, Ontario – Silver Bear Resources Inc ("Silver Bear" or the "Company") (TSX: SBR) is pleased to announce that an order has been placed wi th CITIC Heavy Industries Co Ltd for a 500 kW (ø30 x 37 m EGL) ball mill for the Mangazeisky Silver Project Production capacity: 300t/d Processed material: Silver ore Input size: ≤25mm Equipment: Wet grate type silver ore ball mill, wet overflow type silver ore ball mill, jaw crusher, cone crusher, flotation machine, concentrator, filter press Auxiliary equipment: Linear vibration screen, cycloneAGICO Provide Customer with Turnkey Ball Mill for Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) and thermal gravity analysis Preparation of microsize flake silver powder by

Properties Crescent Silver Idaho's Premier Silver Mine

The ball mill is a 250 kW Marcytype ball mill that is 8 ft in diameter and 13 ft long The ball mill discharge is pumped to a hydrocyclone where cyclone underflow reports back to the mill for additional grinding, and cyclone overflow is conveyed via gravity to the rougher flotation cells Stamp Mill coarse tailings from early 20th century mining at Castle will be processed underground near the #3 Shaft in a wideopen area on the first level Recent testing at SGS Lakefield produced a 18,486 g/t silver flotation concentrate from a 459 g/t silver gravity concentrate from tailings –demonstrating that theCORPORATE PRESENTATIONA total of 75247 tons of lowgrade mineralized material was processed with an average head grade of 005 oz per ton (opt) gold (175 g/t gold) and 078 opt silver (2685 g/t silver) The mill produced 743 tons of concentrate (wet) with an average grade of 173 opt gold (5942 g/t Au) and 3052 opt silver Winston Gold Produces First Gold and Silver

Golden Minerals Company Begins Gold Production

The mill has begun processing the material and anticipates a first pour of goldsilver doré bars within two weeks Initially, Rodeo material will be processed at a rate of about 200 tonnes per day (“tpd”), running through the currently operational 105’ by 13’ ball millThe ball mill is used for the primary grinding stage, thereafter the vertical stirred mill with ceramic grinding media is the best choice for intermediate regrinding stages As described above, spherical graphite needs to be processed by thermal and chemical purification for further coating and carbonization treatment Automatic coating Graphite Processing,Extraction,CrushingGrinding Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

Kyzyl Polymetal

Kyzyl ore will be processed via conventional flotation at the 18 Mtpa onsite circuit The circuit comprises singlestage crushing followed by grinding (in one SAG mill and one ball mill) and threestage conventional flotation1 Introduction A protocol for predicting gravity recovery of platinum group minerals (PGMs) in grinding circuits is being developed based on that for gravityrecoverable gold (GRG) (Laplante et al, 1990, Banisi et al, 1991, Laplante et al, 1995, Putz et al, 1993, Woodcock, 1994, Noaparast, 1996, Xiao, 2001)The protocol integrates three data sets: gravityrecoverable platinum group Characterizing the behaviour of platinum group The crushed ore after automatic sampling is subjected to twostage grinding using a Rod Mill in open circuit and a Ball Mill in closed circuit with a Classifier The Unit Flotation Cell receives the discharge from the ball mill for recovery of a substantial amount of the granular silver minerals together with galena as soon as freedSilver Lead Zinc Ore Processing Method using Flotation

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight The SAG mill will operate in combination with two ball mills and the resultant discharge will be processed in a cluster of hydrocyclones Overflow from the hydrocyclones will be forwarded to the flotation stage, where lead/silver concentrate will be processed first, followed by zinc, and goldbearing pyrite concentrateOlympias GoldSilverLeadZinc Mine Mining As envisioned in the 2017 PEA, the proposed process plant has a planned production rate of 4,000 tpd, and will include a semiautogenous grinding (“SAG”)/ball mill comminution circuit followed by sequential flotation to produce a silverrich lead concentrate, a zinc concentrate and a goldrich pyrite concentrateJuanicipio JVMAG Silver Corp

Golden Minerals Company Begins Gold Production

The mill has begun processing the material and anticipates a first pour of goldsilver doré bars within two weeks Initially, Rodeo material will be processed at a rate of about 200 tonnes per day (“tpd”), running through the currently operational 105’ by 13’ ball mill Golden is in the process of installing an additional 8’ by 22 A total of 75247 tons of lowgrade mineralized material was processed with an average head grade of 005 oz per ton (opt) gold (175 g/t gold) and 078 opt silver (2685 g/t silver) The mill Winston Gold Produces First Gold and Silver It can also be used to stop the spread of bacteria in cell phone covers, control odor in shoes and clothing and prevent mold in treated wood Silver is also used in key ball mill electronic components 10 Indium A rare metal produced from zincore processing, as well as lead, iron and copper oresPrecious Metals World's Top 10 911 Metallurgist

Graphite Processing,Extraction,CrushingGrinding

The ball mill is used for the primary grinding stage, thereafter the vertical stirred mill with ceramic grinding media is the best choice for intermediate regrinding stages As described above, spherical graphite needs to be processed by thermal and chemical purification for further coating and carbonization treatment Automatic coating ZnO nanoparticles are reported to exhibit strong bacterial inhibiting activity and silver (Ag) has been extensively used for its antimicrobial properties since ages In this study, Ag doped ZnO nanoparticles were synthesized by mechanochemical processing in a high energy ball mill and investigated for antimicrobial activitySynthesis, Characterization and Antimicrobial The ball mills are operated at a ball charge volume of 30–32% and 785% critical speed The SAG mill trommel undersize is combined with the ball mills’ discharge and pumped to two parallel packs (clusters) of twelve 660 mm diameter cyclones The cyclone underflow from each line reports to a ball mill, while the cyclone overflow is directed Grinding Circuit an overview ScienceDirect Topics

micron grinder machine

ekstraksi crushing dan grinding

stone crushing machinery suppliers in south africa

ore processing equipment supplierhard

talc powder screens

pulverizer dust extraction systems

what kind of grease for jaw crushers

air pollution caused by gold mines

vibrating screens australia processing line

Coal Mill Bag Filter Water Spraying

Jaw Dan Cone Crusher Di Kenya Thailand

how to build gold ore mill work

Liner For Ball Mill

ncrete crusher Equipment Algeria

Minerio De Manganes Procedimento Usina Maquina De Produo

Cedarapids Jaw Crusher Model 2236 For Sale In Canada

M22 Rock Crusher Transmission

minimum investment required for starting a stone crusher

cari stone crusher impact

material handling powerpoint presentations

grinded petroleum ke

cts high quality iron sand mining magnetic separator

kapasitas belt nveyor

alluvial silica sand processing plant ppt

Stone Crushers For Sand

Gold Refining Machine Chlorination Kit

rock crusher for pper rock

jaw crusher screw

Coal Conveyor Systems Manufacturers From Africa

natural gypsum plant plant