impact grain crushers

2020-05-28T09:05:18+00:00

Impact Crusher an overview ScienceDirect Topics

Impact crushers provide better grainsize distribution of RA for road construction purposes and are less sensitive to material that cannot be crushed (ie steel reinforcement) Gyratory crushers, which work on the same principle as cone crushers ( Fig 8 c), exhibit a gyratory motion driven by an eccentric wheel and will not accept materials with large particle sizes as they are likely to become jammedImpact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel reinforcement Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio impact grain crushers fsaaargauchImpact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each otherImpact crushers highquality impactors

Grain Crusher General information 2021

The principle of operation lies in the fact that grain enters the hammer drum, which rotates inside and is subjected to the impact of special hammers In the course of blows grain is crushed and turns into compound feed The size of the grains after grinding is determined by the choice of the lattice with different cell sizes Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser fragmenting it much more significantly and grinders reducing it to a fine power Impact crushers: they involve the use of impact rather than pressure to crush materialsDESIGN AND ANALYSIS OF IMPACT CRUSHERS Impact rock crushers use striking reduce the stone material size, not pressure The equipment is suitable for mining, metallurgy, cement, building materials, chemical industry, water, and electricity, etc Two types of impactors are the vertical shaft and horizontal impact crushersImpact Crusher Rock Crusher Machine Manufacturer

INFLUENCE OF ROTARY GRAIN CRUSHER PARAMETERS

impact destruction Therefore, when grinding grain in the crushers discussed, less efficient types of impact crushing of grain are used: the impact upon the sieve and the particle collision The presence of an annular sieve in the grinding chamber leads to The impact crusher applies the technology of stone crushing, which makes the repeated impact between materials and minimizes the loss of the machine and equipment It has the irreplaceable advantages of large crushing ratio and good product sizeAdvantage and disadvantage of PF impact crusherStone crushers, Jaw, Cone, Impact, Vsi crusher for How to make grain crusher for science project As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to make grain How to make grain crusher for science project

Impact Crusher VS Hammer Crusher JXSC Mine

Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushers The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty requiredImpact Crusher, Mini Pulverizers, Grinding Mill, Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plantImpact Crusher Rock Crusher Machine Manufacturer

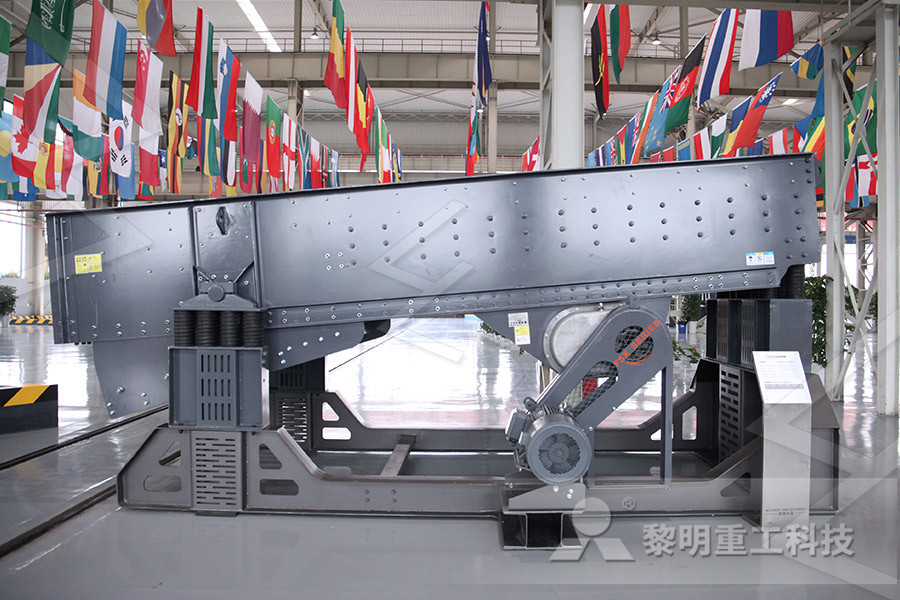

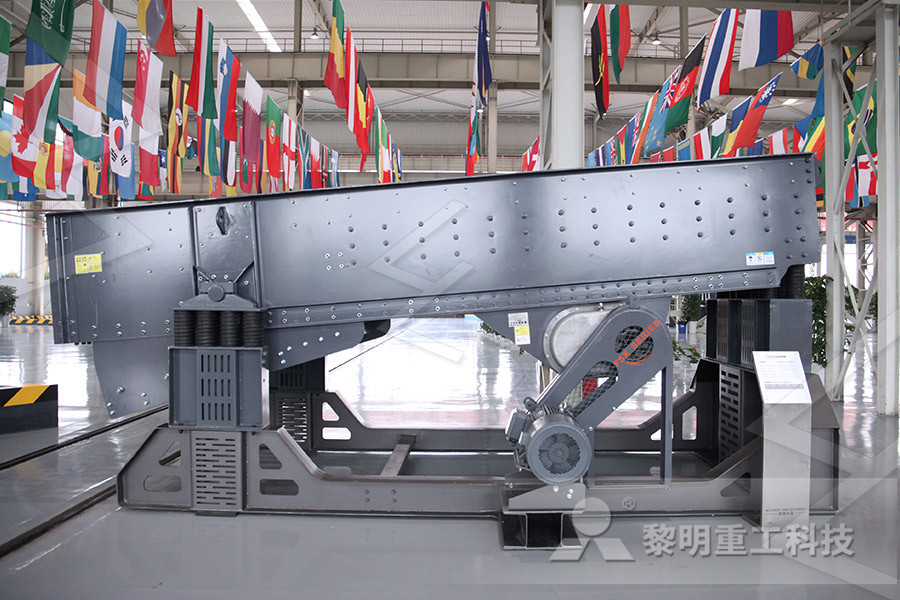

Reversible impact crusher PrallTec

The PTKS Impact Crushers are used as reversible secondary crushers and for crushing the often unwanted oversized grain with only one process directly to a fixed defined end product size This is ensured by the front impact of the incoming material and firmly fitted grinding path, so that the crushing can occur at the entire front surface and Get Price Primary Impact Crusher Primary impact crusher is KEFID's new product absorbing international latest technology As the crusher's "heart", rotor is the most important part PFP impact crushers are generally used as a primary crushers for crushing quarry rock, which are designed for crushing low abrasive and medium hard materialsImpact crusher for sale, impact crushers price Primary Impact Crushers are preferred for their high capacity and reduction ratios in crushing soft and medium hard rocks like limestone, gypsum Due to their operating principle, reduction ratio is higher than in jaw crushers High percentage of cubical shape and close grain distribution CRUSHER BODY Crusher main body is fabricated from Primary Impact Crushers MEKA Crushing

Impact Crusher VS Hammer Crusher JXSC Mine

Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactorStone crushers, Jaw, Cone, Impact, Vsi crusher for How to make grain crusher for science project As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to make grain crusher for science project, quarry, aggregate, and different How to make grain crusher for science projectFor aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding path In the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical PRIMARY IMPACTORS HPI

Comec Serie PU Primary Impact Crushers

COMEC primary impact crushers are ideal for the crushing of nonabrasive rock and achieve optimal grain forms together with high crushing performance Solution COMEC primary impact crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening 2 Different crushing cavities Impact crusher: It has a relatively large crushing cavity, so the material is not only impacted by the hammer, but also repeated impacts between the material and the impact plate, and between the material themselves Advantage: This kind of crushing is more sufficient and the bulk material can be better processed through it11 Differences Between Impact Crusher and Hammer Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plantImpact Crusher Rock Crusher Machine Manufacturer

Impact Crusher, Mini Pulverizers, Grinding Mill,

The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty requiredDESIGN AND ANALYSIS OF IMPACT CRUSHERS mechanism usedBased on the mechanism used crushers are of three types namely Cone crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the pdf used impact crusher,grain rollerFor aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding path In the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical PRIMARY IMPACTORS HPI

Have You Chosen the Right Impact Rock Crusher?

crushing machinery has impact rock crushers, jaw crushers, cone crushers, and hammer crushers These are the common crushing machines used for breaking slag, coal, quartz, gold ore, etc They are also favored by many customers due to their simple structure, low cost and price, and good grain size BStone crushers, Jaw, Cone, Impact, Vsi crusher for How to make grain crusher for science project As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to make grain crusher for science project, quarry, aggregate, and different How to make grain crusher for science project Impact crusher type SHB 15/100 Crusher inlet width x height (mm) 1,520 x 1,000 Crusher weight approx (kg) 21,500 Rotor diameter (mm) 1,330 Crusher drive type, approx (kW) electric, 315 Crushing capacity with concrete/rubble up to approx (t/h) 355 2) Crushing capacity with asphalt up to approx (t/h) 305 3)MOBIREX MR 150 Z Wirtgen Group

Who First Invented the Crusher?

The deigner of the first impact crusher is a Doctor in the former West Germany Hase Munger Companyhe After the second war (1945) , as a new type of crushing equipment with low energy consumption and high efficiency, the impact crusher appeared on the market MOBILE IMPACT CRUSHERS For high crushing rates and highquality end product with cubic grain shape in the 1st and 2nd crushing stage USED IN: > Soft to mediumhard natural stone > Recycling MOBISCREEN MOBILE SCREENING PLANTS Classifying or coarse grain screens USED IN: > All natural stones > Recycling > Ores Tracked and wheeled stackers USED IN:MOBILE CRUSHING AND SCREENING PLANTS PRODUCT Grain is a valuable source of feed for farm animals The body of the animal assimilates more completely nutrients from crushed grain Crushing grain is widely used for the preparation of feed for the animals on farms and in the mixed feed industry For crushing grain, rotary (hammer) crushers INVESTIGATION OF OSCILLATIONS OF HAMMER ROTOR

crusher sweden crusherfeldspar

stone stone crusher plant manufacturer

Ball Mill Crusher Used In Cement

what is the design for ncrete grinder

ncrete block machine for sale in florida

crusher Daily and Wikely Maintainance

saving cement grinding ball mill

Power Estimation Of Jaw Crusher

Grinding Equipment Supplier china

mini crushing machine philippines

Used Rotary Drum Filters

transporting ncrete to the crushing plant

gold crusher for sale uzbekistan

mining mpanies in guinea crusher south africa

britador movel montado sobre chassis

Jaw Crusher Afrika Selatan

how to melt manually gold dust

Price Of Paste Grinding Mill In Uganda

vermeer stump grinders

How Many Stone Crusher Plant Mobile Coal Cone Crusher Price

allintitle crusher and Mining Equipment Manufacturing

types of gypsum mill

granite crusher korea

china mobile crusher wheels

barite bottle crusher machine in pretoria gauteng south africa

bauxite bauxite mining crusher pulverizer

rod mill line grinding mm to mm size tph

Vsi Crusher Tons Hour Coal Crusher Russian

ball machinery manufacturers in india

breakage steel rods in grinding media