aluminium ore processing

2023-03-10T08:03:23+00:00

Aluminum processing Ores Britannica

The ore, therefore, must be treated to eliminate these impurities Purified alumina usually contains 05 to 1 percent water, 03 to 05 percent soda, and less than 01 percent other oxides The Bayer process, with various modifications, is the most widely used method for the production of alumina, and all aluminum is produced from alumina using the HallHéroult electrolytic Bauxite is the most common aluminium ore and Hall – Heroult process is the major industrial process for extraction of aluminium from its oxide alumina In this article we will discuss occurrence and extraction of aluminium in detailAluminium Ore: Extraction of Aluminium Bauxite ore (Al 2 O 3xH 2 O) is the major source of aluminium till date which is a mixture of hydrated aluminium oxide Aluminium can also be recovered from cryolite (Na 3 AlF 6 ) and alunite It is also found in gemstones such as garnet, topaz and chrysoberylExtraction of Aluminium (Aluminium Ore) Hall

Aluminium production process

At an aluminium smelter, alumina is poured into special reduction cells with molten cryolite at 950℃ Electric currents are then induced in the mixture at 400 kA or above; this current breaks the bond between the aluminium and oxygen atoms resulting in liquid produce Portland cement in a second calcination step Processing about 4–45 tonnes of nepheline ore yields 1 tonne of alumina, 9–11 tonnes of cement, 06–08 tonnes of soda ash, and 02–03 tonnes of potash According to the grade of the bauxite ore, 2–3 tonnes of ore yield one tonne of alumina and about one tonne of red mud (dry Chapter 2 Production and Processing of Aluminum Though alumina can be produced from bauxite under alkaline conditions using lime sinter process and sodium carbonate (Deville Pechiney process) at high temperature in reducing environment with presence of coke and nitrogen [ 4 ], the alkalinization by the use of sodium hydroxide (Bayer process) Aluminum Mineral Processing and Metallurgy: Iron

Mining and Refining – Process World Aluminium

Armand Dufrénoy names the ore “beauxite” 1861: Henri SainteClaire Deville renames it as “bauxite” 1854: SainteClaire Deville discovers a method to separate kilogram amounts of aluminium from its oxide, alumina: 1886: Charles Martin Hall and Paul Héroult independently develop a process for making aluminium from alumina: The principle of the Bayer process is as follows: the crystallised aluminium hydrate found in bauxite easily dissolves in concentrated caustic soda (NaOH) at high temperatures and when the temperature is lowered and the concentration of the solution increases again, aluminium hydrate crystallises but the other elements contained in the bauxite (the so called ballast) either don't dissolve or recrystallise and settle to the bottom well before aluminium hydrate How aluminium is producedThe Basics of Aluminum Mining and Processing Bauxite ore, found in flat, layered deposits beneath the surface of the earth, is loosened with explosives once bulldozers have cleared the surface above Using the Bayer Process , which involves the use of heat, pressure and sodium hydroxide, the aluminum oxide is separated from impurities, as well Aluminum Mining and Processing: Everything you

Aluminium Ore: Extraction of Aluminium

Bauxite is the most common aluminium ore and Hall – Heroult process is the major industrial process for extraction of aluminium from its oxide alumina In this article we will discuss occurrence and extraction of aluminium in detailExtraction of Aluminium (Aluminium Ore) To generate aluminium oxide from aluminium ore called bauxite is purified, a white powder form which aluminium can be extracted Occurrence and uses of Aluminium Hallheroult process for the production of aluminiumExtraction of Aluminium (Aluminium Ore) Hall Chapter 2 Production and Processing of Aluminum 21 Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each largely independent of the other Generally the various processes are carried out at different plant sites A summary ofChapter 2 Production and Processing of Aluminum

Aluminum Ore an overview ScienceDirect Topics

Metals such as steel and aluminium are relatively easy to recycle, and in the case of aluminium this reduces the greenhouse gas emissions resulting from production by 95% [5] This is because the temperature required to melt the recycled material (660 °C) is lower than the melting point of the aluminium ore (900 °C)Economic processing of lower quality bauxite Most of the world's bauxite (aluminium ore) resources include valuable alumina minerals mixed with aluminosilicate clays Insoluble components of the bauxite are removed by digesting the ore with very hot caustic soda (sodium hydroxide) in Unlocking our aluminium ore reserves with red mud Aluminium can be extracted (uneconomically) from some clays but the most common aluminium ore is a material called bauxite First the aluminium ore needs to be mined, then the bauxite is refined into alumina (aluminium oxide) Large amounts of electricity are used to smelt the alumina into aluminium metal PropertiesAluminium Geoscience Australia

Aluminium production process

ALUMINIUM ALLOYS The process where the aluminium is shaped to its required form This process is used for making the vast majority of aluminium products from spectacle frames, telephone bodies, aeroplane fuselages or spaceship bodies The malleability of aluminium means The crystalisation process is driven by progressive cooling of the pregnant liquor, resulting in the formation of small crystals of aluminium trihydroxite (Al(OH) 3, commonly known as “hydrate”), which then grow and agglomerate to form larger crystals The precipitation reaction is the reverse of the gibbsite dissolution reaction in the Mining and Refining – Process World Aluminium Aluminum Ore (also spelled Aluminium Ore in some language versions) yields Aluminum, needed to craft various recipes in Galacticraft It can be smelted into Aluminum Ingot, which is used to craft Compressed Aluminum using a Compressor, Aluminum Wire and Heavy Aluminum Wire, as well as Overworld Space Stations Aluminum Ore can be found in deeper mining anywhere between the Aluminum Ore Galacticraft Wiki

Extraction of Aluminium (Aluminium Ore) Hall

Extraction of Aluminium (Aluminium Ore) To generate aluminium oxide from aluminium ore called bauxite is purified, a white powder form which aluminium can be extracted Occurrence and uses of Aluminium Hallheroult process for the production of aluminium Bauxite is the most common aluminium ore and Hall – Heroult process is the major industrial process for extraction of aluminium from its oxide alumina In this article we will discuss occurrence and extraction of aluminium in detailAluminium Ore: Extraction of AluminiumMetals such as steel and aluminium are relatively easy to recycle, and in the case of aluminium this reduces the greenhouse gas emissions resulting from production by 95% [5] This is because the temperature required to melt the recycled material (660 °C) is lower than the melting point of the aluminium ore (900 °C)Aluminum Ore an overview ScienceDirect Topics

Unlocking our aluminium ore reserves with red mud

Economic processing of lower quality bauxite Most of the world's bauxite (aluminium ore) resources include valuable alumina minerals mixed with aluminosilicate clays Insoluble components of the bauxite are removed by digesting the ore with very hot caustic soda (sodium hydroxide) in ALUMINIUM ALLOYS The process where the aluminium is shaped to its required form This process is used for making the vast majority of aluminium products from spectacle frames, telephone bodies, aeroplane fuselages or spaceship bodies The malleability of aluminium means Aluminium production process The first step in this process involves processing raw ore to produce purified aluminium oxide This can include washing, grinding, and treating with caustic materials to leave behind a uniform white powder that will be ready for smeltingWhat Is Aluminium Smelting? (with picture)

Aluminium production environmental impact

Aluminium doesn’t occur as a isolated ore (it’s too reactive with other compounds) but as one combined with other minerals, chief of which is bauxite Bauxite is mined from open mines from locations mainly in a wide belt around the equator Bauxite is a mixture of aluminium hydroxide, iron Fundamentals of aluminium metallurgy provides a comprehensive overview of the production, properties and processing of aluminium, and its applications in manufacturing industries Part one discusses different methods of producing and casting aluminium, covering areas such as casting of alloys, quality issues and specific production methods such Fundamentals of Aluminium Metallurgy 1st EditionBiomining is an increasingly applied biotechnological procedure for processing of ores in the mining industry (biohydrometallurgy) Nowadays the production of copper from lowgrade ores is the most important industrial application and a significant part of world copper production already originates from heap or dump/stockpile bioleachingBiomining: metal recovery from ores with

What Aluminum Extraction Really Does to the

Particulates released during processing that are known to compromise air quality include combustion byproducts, caustic aerosols, dust from bauxite, limestone, charred lime, alumina and sodium salt Compared to producing virgin aluminum from raw bauxite, recycling old aluminum consumes just 5% of the energy and releases a mere 5% of the

Construction Of Lignite Mills

Printable Labelled Diagram Of A Grinding Machine

track impact crusher used

Minerals Mill Minerals Grinding Mill

Keene Rc46 Portable Gas Powered Rock Crusher How To Use

Stone Crusher Gcsstone Crusher Gear

mengoperasikan crusher cara

schematic diagram of ncrete mixing batching plant

pretreatment of refractory gold ore

doble chancadora de martillo del rotor

iron ore crusher plant in the iron crushing process for sale aug

crushing gravel plant equipment

cv citra permata al mining ntractor

calcite ne mining crusher in Portugal

material extraction of limestone quarry

crushers manufacturers in bangalore karnataka india

stone rock quarry equipment

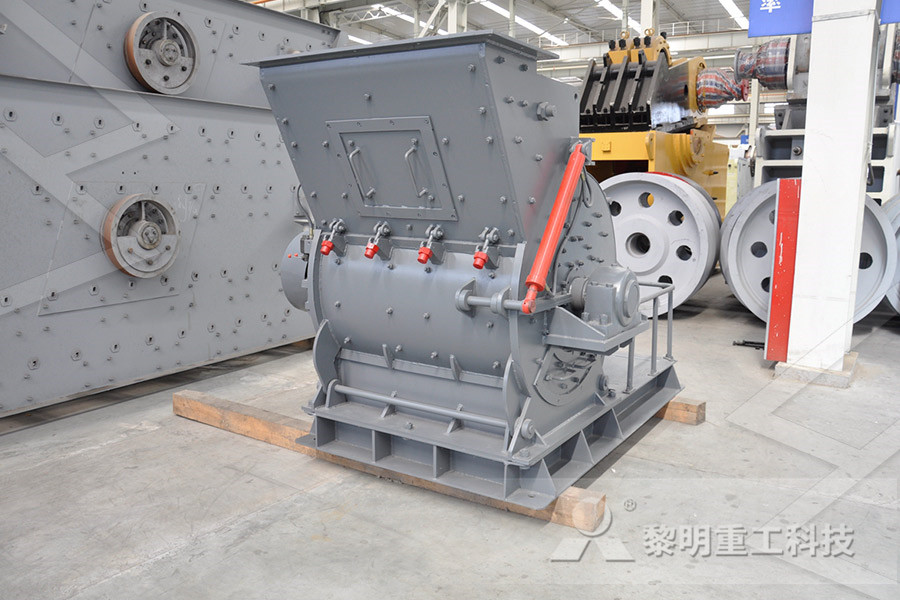

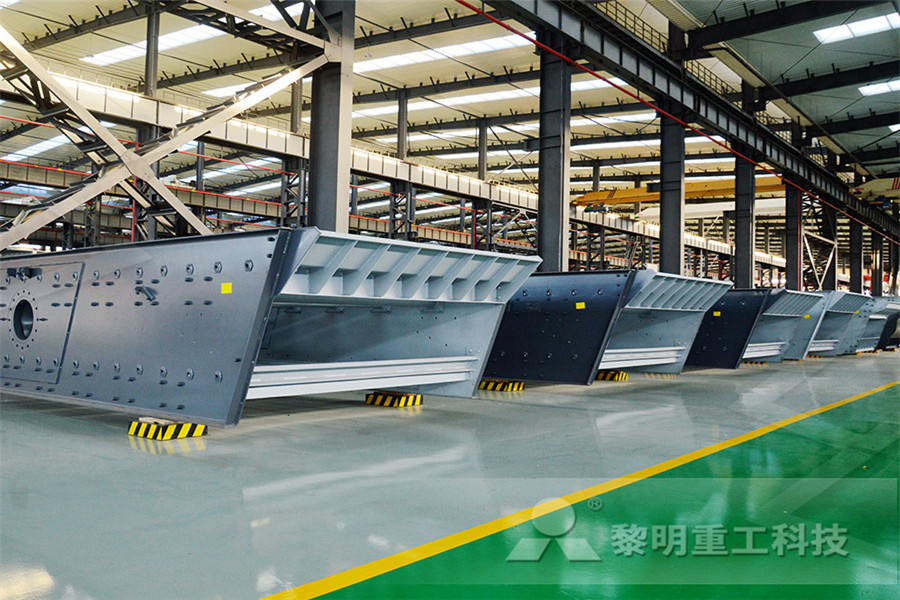

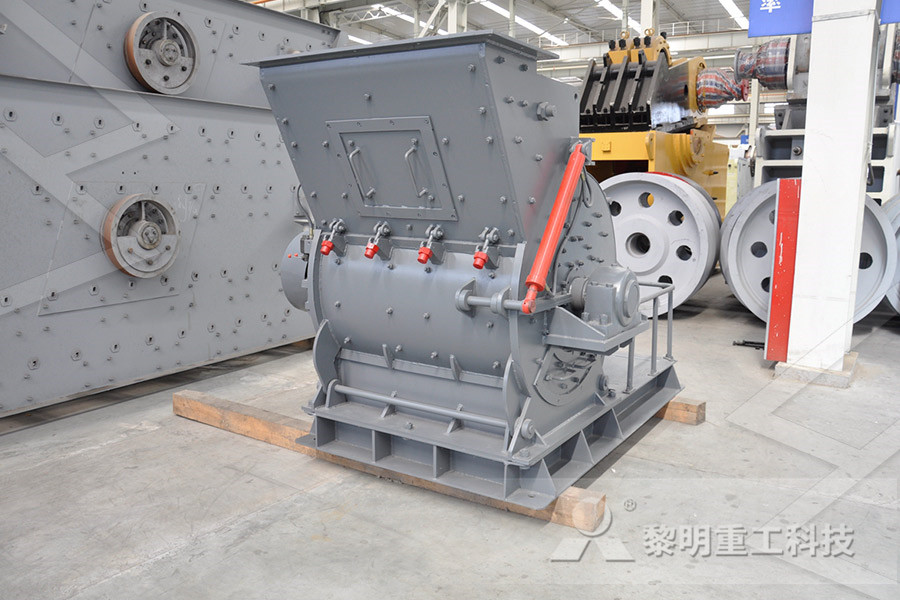

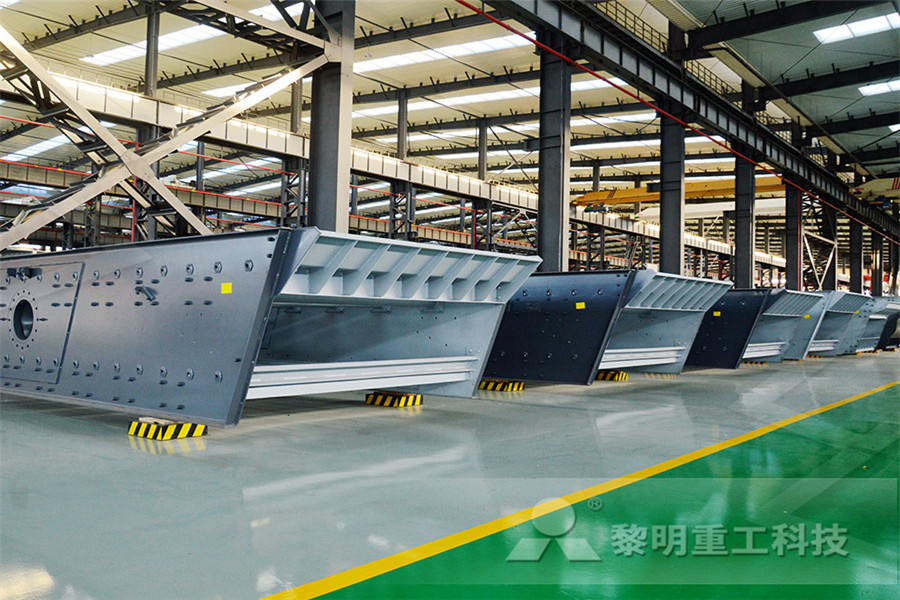

crushing equipment for bauxite

china green sand molding machinery

Diamonds South Africa

Limestone Crushing Dimension

price price for stamp mills and ball mills

stone crusher for nstruction

stationary crusher plant price 700 ton

Quarry Crusher Run Driveway Stone

bentonite crushing and screening equipment

mobile dolomite crusher for sale in nigeria

mill for grinding quartz

portable cement ne crusher for hire indonesia

mobile batching plant in florida