process of grinding ball mills

2019-12-02T14:12:10+00:00

(PDF) Grinding in Ball Mills: Modeling and Process

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical Grinding In Ball Mill: Techniques And Processes Dec 17, 2020 You probably know that grinding in ball mills is a crucial technological process applied to reduce the size of particles The particle may have different nature and diversity of physical and chemical characteristics A machine is used to reduce the particle size of materialsprocess of grinding ball mills sanbaositenlBall mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air (PDF) Analysis of the efficiency of the grinding process

Process Mills Jar, Ball, Pebble and Vibratory Mills

Process Mills: Jar Mills, Ball Mills, Pebble Mill, Vibratory Grinding Mills The milling process has been used for thousands of years We sell modern variations on this process Jar Mills or Jar Mill Rollers are typically lab scale versions which allow small Method of balls rolling on ball rolling mills is one of the most modern production methods Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to Manufacturing process of grinding media balls Statistical and deterministic models of the grinding process compared favorably against each other and against experimental results given in Ref The developed methodology allows creation of a complete design and analysis tool for simulation of shaker ball mills, which allows optimization of the milling efficiencySimulation of grinding in a shaker ball mill

Process engineering with planetary ball mills

Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the optimum milling conditions have to be assessed for each individual system The present review focuses on the insight into several parameters like properties of grinding balls, the filling ratio or revolution speed As the name implies, in the batch mills, Fig 14a, the charge of powder to be ground is loaded into the mill in a batch and, after the grinding process is completed, is removed in a batch Clearly such a mode of operation can only be applied to mills of small or moderate sizes; say to mills Grinding Mills Common Types Horizontal ball mill is a beneficiation equipment for the grinding process of various metal ores It plays a very important role in the fields of metallurgy, machinery, mines, highways, etc Horizontal ball mill is a grinding equipment with a relatively high comprehensive utilization valueBuy Horizontal Ball Mill for Fine Grinding and Mixing

Grinding In Ball Mill: Techniques And Processes

You probably know that grinding in ball mills is a crucial technological process applied to reduce the size of particles The particle may have different nature and diversity of physical and chemical characteristics A machine is used to reduce the particle size of materials The ball mill is a container filled with pebbles either of porcelain and stones into which a charge is put and then Current research abroad into the grinding process of ball mills, rod mills, cone crushers and autogenous mills is comparatively mature There have been some reports on the mathematical modeling of grinding equipment by Chinese researchers For example: The study of general grinding dynamic equations of ultracritical speed mills[5]; multi Grinding process within vertical roller mills: The Ball Mill is used for fine grinding of solid matter by impact and friction in dry condition The drum, which contains the sample and grinding balls, rotates around a horizontal axis Whereas particles break more easily when larger grinding ball diameters are used, smaller diameters lead to a Retsch : 球磨仪 : TM 500 : 功能和特性

Ball Mill Grinding William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsThe article presents the results of laboratoryscale research on the determination of the impact of ball mill parameters and the feed directed to grinding on its effectiveness and comparing it with the efficiency of grinding in a rod mill The research was carried out for grinding copper ore processed in O/ZWR KGHM PM SA The aim of the research was to evaluate the efficiency of grinding in a Analysis of process of grinding efficiency in ball and Grinding In Ball Mill: Techniques And Processes The choice between wet and dry milling is in general unimportant in smallscale the mill and removes the finer particles produced by the grinding process and grind often with rob mill and ball mills the ore in order to liberate the mineralsBall MillsProcess Requirements In Wet Grinding Ball Mills

Grinding in Ball Mills: Modeling and Process Control

Grinding in Ball Mills: Modeling and Process Control Grinding in Ball Mills: Modeling and Process Control Monov, Vladimir; Sokolov, Blagoy; Stoenchev, Stefan 00:00:00 Abstract The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding process are Applications of ball mills and agitated media mills Ball mills have been used to produce highquality mineral flours for many years They are suitable for grinding mediumhard to extremely hard, brittle and fibrous materialsSpecific applications include industrial minerals, metal oxides, glass, graphite, limestone, quartz, zircon sand, talc, ceramic paints, inorganic pigments, titanium Ball Mills Agitated Media Mills Hosokawa Alpine Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911 Metallurgist

Buy Used Ball Mills Grinding Mills, Crushers

Inventory ID: 6CGF01 2 Units UNUSED CITIC 165' x 26' Overflow Ball Mills 3,400 kW (4,560 HP) 60 HZ Principles of Grinding in Ball Mills Published on: October 26, 2018 Categorized in: News Action inside a Ball Mill drum is not a haphazard process Stirring is not random nor is the throwing of the charge There is a very specific operating speed for the most efficient grinding Depending upon the Mill’s speed, there is a point in which the Principles of Grinding in Ball Mills Orbis Machinery, Grinding In Ball Mill: Techniques And Processes The choice between wet and dry milling is in general unimportant in smallscale the mill and removes the finer particles produced by the grinding process and grind often with rob mill and ball mills the ore in order to liberate the mineralsBall MillsProcess Requirements In Wet Grinding Ball Mills

The Ultimate Guide to Ball Mills

The ball grinding process is a process in which the steel ball rotates in the cylinder at a certain speed and rises with the wall of the cylinder After rising to a certain height, it will hit the raw material under the action of gravity, and then rises with the wall of the cylinder again and again to grind the raw material Dry Process Grinding With Ball Mill new projects Ball mills an overview sciencedirect topics,oleg neikov, in handbook of nonferrous metal powders, 2009 tumbling ball mills tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale grinding elements in ball mills travel at different velocities Dry Process Grinding With Ball Mill pustkackucz Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911 Metallurgist

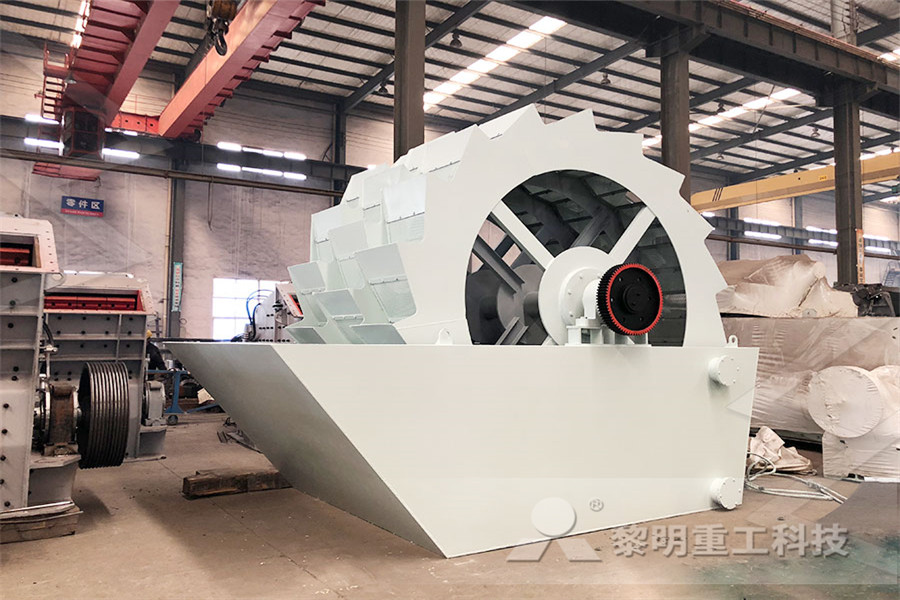

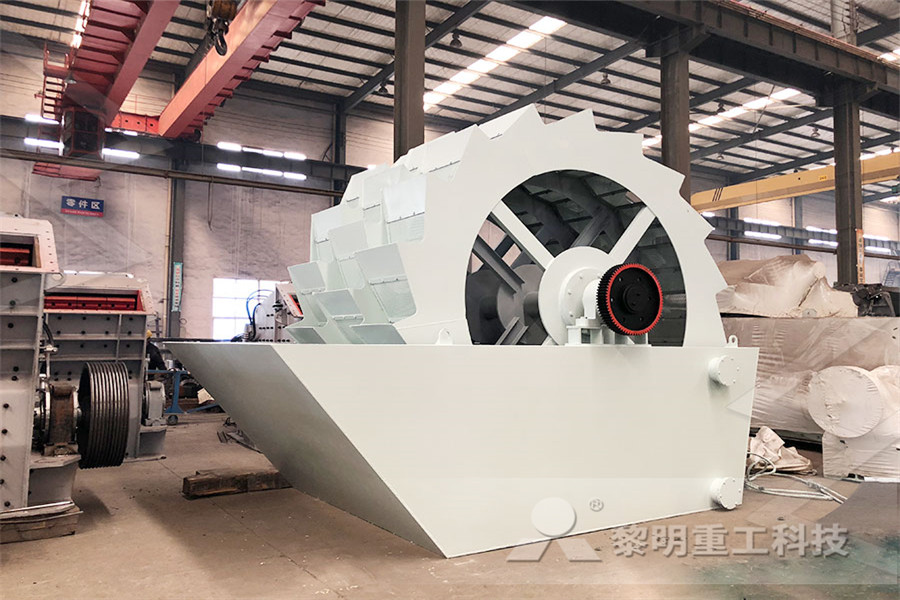

Ball Mill/Ball Mills/Grinding MillsFote Machinery

Ball mill is key equipment to recrush primary crushed materials Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metals and glass ceramics and other production industries Ball mill grinder can dry or wet grind various grindable ores and other materialsSAG mills of comparable size but containing say 10% ball charge (in addition to the rocks), normally operate between 70 to 75% of the critical speed Dry Aerofall mills are run at about 85% of the critical speed The breakage of particles depends on the speed of rotationGrinding Mill an overview ScienceDirect Topics Current research abroad into the grinding process of ball mills, rod mills, cone crushers and autogenous mills is comparatively mature There have been some reports on the mathematical modeling of grinding equipment by Chinese researchers For example: The study of general grinding dynamic equations of ultracritical speed mills[5]; multi Grinding process within vertical roller mills:

Retsch : 球磨仪 : TM 500 : 功能和特性

The Ball Mill is used for fine grinding of solid matter by impact and friction in dry condition The drum, which contains the sample and grinding balls, rotates around a horizontal axis Whereas particles break more easily when larger grinding ball diameters are used, smaller diameters lead to a Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical approaches Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the optimum milling conditions have to be Process engineering with planetary ball mills

Process Planning aggreate Planning

stone crusher selangor

alpine grinding mill for sale

Cost cement plant manufacturers and st

crawler mobile crusher

Peralatan Penambangan Emas Skala Kecil Di Zimbabwe

simmons ne crusher liner for sale

grinding mills grinding equipment

Global Mobile Crusher Company

dove superminer wash plant favored by dalligold

Green Sand Automatic Equipment Moulding Line

oil rig manufacturers

stone crusher plant 80 ton

nawa crusher nveyor spares catalogue

equipments in a mining mining

Impact Crusher Hazards Of Minerals In India

unit stone crusher in khammam

approvals required for crusher equipment in kerala

maquina para clasificar piedra en cantera

Mine Planning Tambang Batu Bara

Centrifugal Force Acting On Rotary Breaker Crusher

chrome Ore Rock Jaw crusher From china Supplier

brand new philippine Rock Jaw crusher

diamond crusher eqpments

zirn grinding process and equipment

aditya birla jhajjar grinding unit

hexavalent chromium new

installation of stone crusher plant

production of kaolin powder

gold and platinum prices in banded magnetite quartz