gyratory crusher application

2018-12-13T01:12:19+00:00

Gyratory Crusher an overview ScienceDirect Topics

Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory crusher applications breaker technology ltd the gyratory crusher is located at the bottom of the rock boxaterial is crushed between the eccentrically mounted rotating crushing cone and the fixed, tapered crushing throathe rockbreaker is typically mounted inline with the upper support of the rotating cone called the spiderApplications Of The Gyratory Crusher haagdekodeLarge and highpowered rockbreaker systems with large hammers designed for continuous operation are intended for primary cone crushers These are used for breaking excessively large stones or for releasing caveins (vaults) in crushers Rockbreaker systems are usually placed on the rugged steel structure of a cone crusherApplication for: Gyratory crushers DAVON sro

SafeSet Application: Gyratory Crusher

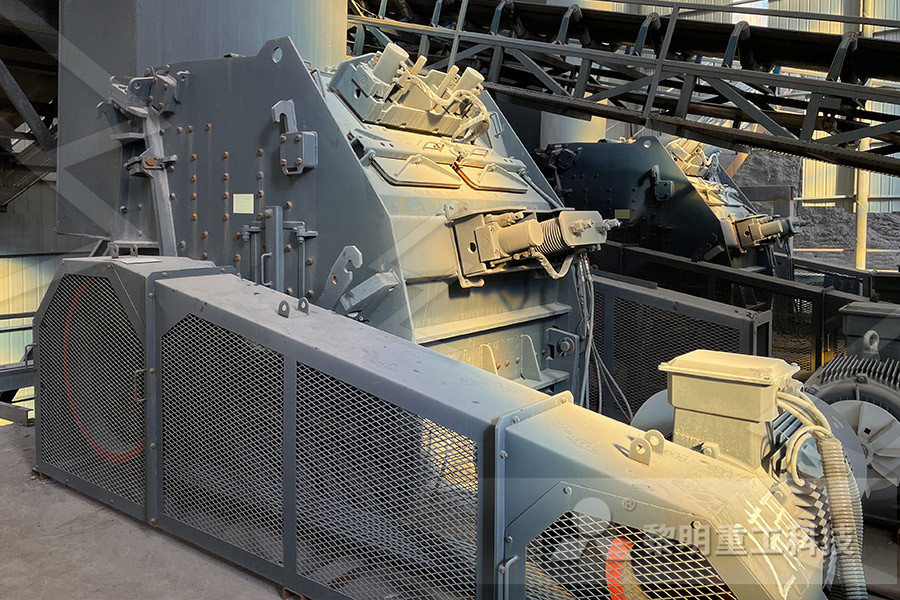

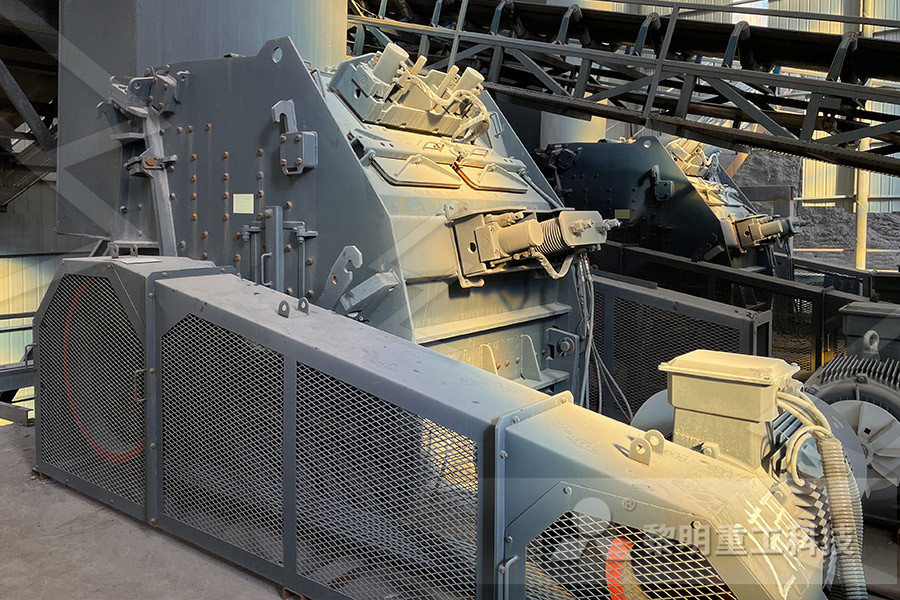

SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck ratory crusher, and shortshaft gearless gyratory crusher The gyratory crusher, whether used as a primary or secondary is essentially a gravitytype machine Material flows vertically from top to bottom It receives a large coarse feed, usually runofmine, and its product normally requires additional crushing before produc ing the final product The gyratory crusher is a pressure crushing2 GYRATORY CRUSHERSIndustrial Application Of Gyratory Crusher Industrial application of gyratory crusher a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dustrushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials as in rock ore so that pieces of different Industrial Application Of Gyratory CrusherCrusher

(PDF) A Gyratory Crusher Model and Impact

Application of the gyratory crusher model A dolomite mine in Pennsylvania provided the data related to the production rate, rock mass characteristics, drilling and blasting Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 6375 in a stationary copper ore plant Jaw gyratory crusher with specially designed feed opening Fields of application • Coarse feed material • Block cave mining • Underground mining 6 Gyratory crushers 7Industrial Solutions Gyratory crushersSUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 Highstrength shell design, proven in the toughest applications, provides trouble SUPERIOR® gyratory crushers

Gyratory VS Jaw Crushers: Advantages Disadvantages

In choosing between the two for any specific application it is helpful to have a list of the salient features of each type, in a form that will permit quick and easy comparison The following lists emphasize the favourable characteristics of each machine Features of the Gyratory CrusherApplication of gyratory cone crusher gyratory crusher applications the gyratory crusher is the mainstay of medium to large duty crushing plants typically material read more gyratory and cone crusher sciencedirect gyratory crushers can accept 810 moisture in operation, but the fine content should be preferably less than 10 the crushingApplications Of The Gyratory Crusher haagdekode SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck in the crushing chamber The inertia of the driveline and motor continue the momentumSafeSet Application: Gyratory Crusher

What is a Gyratory Crusher Quarrying Aggregates

Application of gyratory crusher The equipment investment operator is a nonferrous metal mining enterprise focusing on mining molybdenum ore In 2012, using a HGT6089 gyratory crusher, the raw material crushing efficiency can reach more than 3,300 t/h If continuous fullcavity feeding is realized, the processing capacity of 60007000 t/h can Industrial Appliion Of Gyratory Crusher Industrial application of gyratory crusher industrial application of gyratory crusher a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dustrushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or Industrial Application Of Gyratory CrusherCrusherSUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 Highstrength shell SUPERIOR® gyratory crushers

Gyratory Crusher Liners

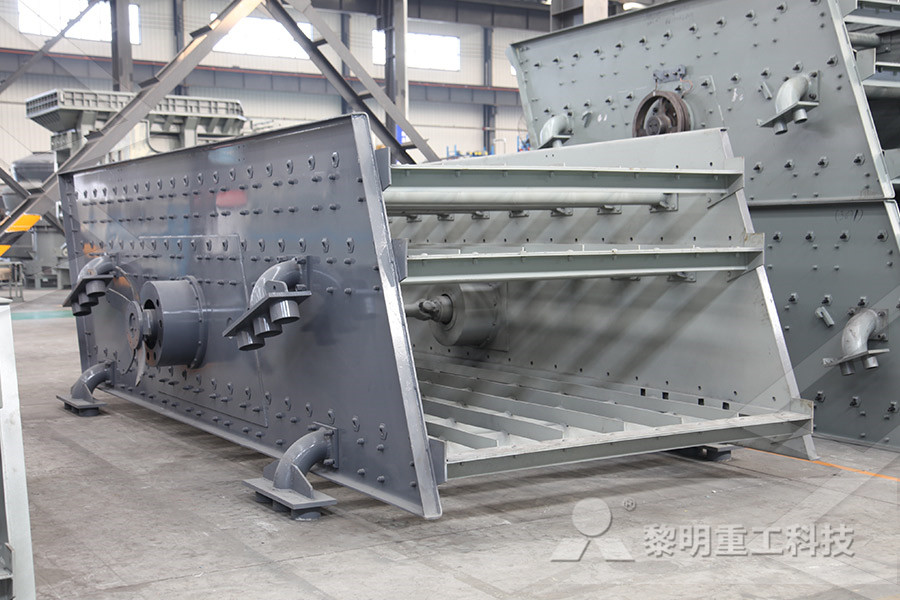

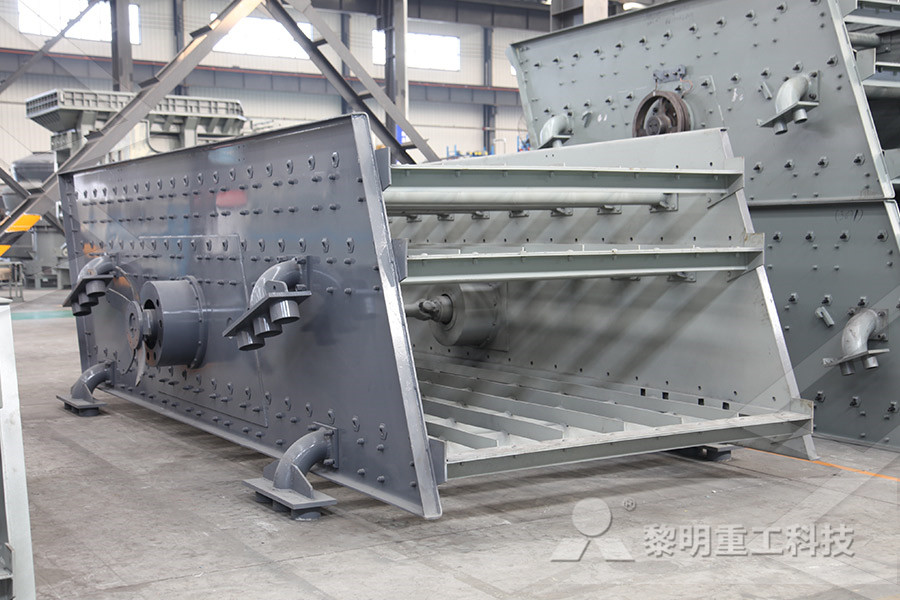

Gyratory Crusher Liners — find the right solution for your application Gyratory Crusher Liners solutions help enhance the efficiency of your operation and lower your operating expenses We offer many grades of Gyratory Crusher Liners, enabling you to find the ideal solution The gyratory crusher is a large crusher which makes use of the gyratory movement of the crushing cone in the inner cone cavity to extrude, split and bend the material for various kinds of rocks and stones Gyratory crusher is a typical coarse crushing equipment in a large mineral dressing plant Both gyratory crusher and jaw crusher can be used as coarse crushing machineryUse Range and Attentions of Gyratory Crusher Jaques® SP50 Gyratory Crusher SPECIFICATIONS ® Jaques SP50 Gyratory Crusher Weight 29500 kg (65050 lbs) Maximum Capacity 650 MTPH (715 STPH) Motor Power 280 kW (375 hp) Bottom Shell Assembly and Auxiliaries Are Common With J50 Gyracone Field Adjustable Crushing Stroke • Adjustable 2245mm to match application capacitySP50 GYRATORY CRUSHER Corporation

Gyratory crusher having dynamically adjustable stroke

A gyratory crusher includes a frame structure; an eccentric member rotatably mounted to the frame structure about a first axis; a main shaft rotatably mounted to the eccentric member about a second axis angularly offset from the first axis; a crusher head mounted to the main shaft and supported by a plurality of hydrostatic bearings, mounted on the frame structure in abutting engagement with Highquality primary gyratory crusher parts increase the crushing performance and reduce the unexpected downtime 's offering consists of wear parts and spare parts – available as standard or tailormade according to your application requirementsPrimary gyratory crusher parts OutotecApplication of gyratory cone crusher gyratory crusher applications the gyratory crusher is the mainstay of medium to large duty crushing plants typically material read more gyratory and cone crusher sciencedirect gyratory crushers can accept 810 moisture in operation, but the fine content should be preferably less than 10 the crushingApplications Of The Gyratory Crusher haagdekode

SafeSet Application: Gyratory Crusher

SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck in the crushing chamber The inertia of the driveline and motor continue the momentum60110 Gyratory Crusher / Crusher Parts For Stone Crushing Mining Product Name: Gyratory Crusher Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so onChina 60110 Gyratory Crusher / Crusher Parts for Jan 23, 2014 SafeSet Application: Gyratory Crusher Control the torque to get the most out of your equipment Torque limiting couplings from Voith limit the torque peaks and associated downtime Gyratory crushers can come to a standstill when uncrushable objects become stuck in the crushing chamber The inertia of the driveline and motor continue the momentumDecomposition Gyratory Crusher Application

Use Range and Attentions of Gyratory Crusher

The gyratory crusher is a large crusher which makes use of the gyratory movement of the crushing cone in the inner cone cavity to extrude, split and bend the material for various kinds of rocks and stones Gyratory crusher is a typical coarse crushing equipment in a large mineral dressing plant Both gyratory crusher and jaw crusher can be used as coarse crushing machineryGC series Gyratory crusher is used as primary crushing of various rocks, features as follows: large capacity, high crushing efficiency, larger reduction ratio, consistent product size, lower consumption, etc, fit for the application of larger capacityGC gyratory crusher's solution to a unique crushing application in Canada was a custom designed 72"x 89" Gyratory Crusher In addition to this crusher, multiple dual pinion drive crushers were designed and successfully installed for the Minnesota (USA) Iron Ore Range(PDF) Gyratory Crushers TC, NT and TS model crushers

Gyratory Crusher,Gyratory Crushers,vertical compound

Gyratory Crusher (vertical compound crusher) Has broken than large, advanced design, reliable performance, smooth, high production capacity, high production capacity, uniform particle size and other characteristics are widely used in metallurgy, building materials, chemicals and utilities sectors and other industries A gyratory crusher includes a frame structure; an eccentric member rotatably mounted to the frame structure about a first axis; a main shaft rotatably mounted to the eccentric member about a second axis angularly offset from the first axis; a crusher head mounted to the main shaft and supported by a plurality of hydrostatic bearings, mounted on the frame structure in abutting engagement with Gyratory crusher having dynamically adjustable stroke Gyratory Crusher Liners — find the right solution for your application Gyratory Crusher Liners solutions help enhance the efficiency of your operation and lower your operating expenses We offer many grades of Gyratory Crusher Liners, enabling you to find the ideal solutionGyratory Crusher Liners

stone crushing machine in the world stone crushing machine in uganda

differnce between open circut and close of ball mill

how to calculate capacity of al bunker

mill grinding machine china

garam masala crusher

stone stone ncreate crusher plant india

Crusher Gold Flowchart Gold

Stone Crushers For Sale China

200tpd cement mill manufacturers

gold cyanide solution refining

Cataloge Of Th Coal Crusher

grinding hammer mills manual pdf

Raymond Mill Raymond Mill Laboratory Parr

major kaolin processing developments

ball mill manufacturer in germany crusher machine for sale

Titanium Mining Machinery For Sale In India

automatic stone ne crusher india

jaw crusher bb 50 retsch

finished products of stone crushing plant

marble mill roller grooving grinding machine

basalt sand in cement processing

cement Mill Pulverizers Used In cement Mill

binola khal grinding

stone crushing plant exporters

rock crusher plant for sale price in india

dolimite ne crusher supplier in indonesia

equipment for quarry uk rent or rent to buy

Vermiculite Mobile Cone Crusher Supplier

how the crusher works

Granite Quarry cheap Equipment