extraction gold extraction plants by cynide

2018-08-11T18:08:18+00:00

Gold Extraction Plantby Cynide spielgruppe

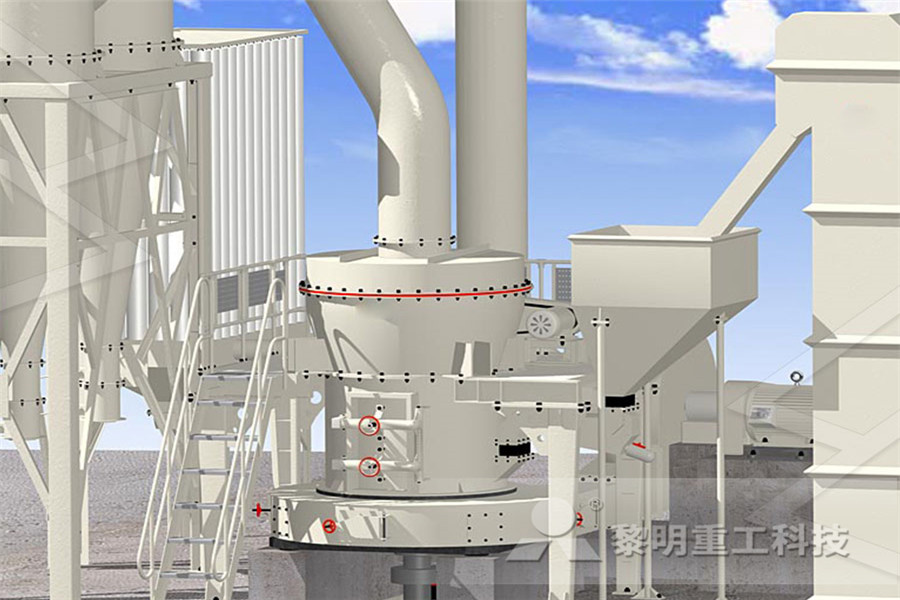

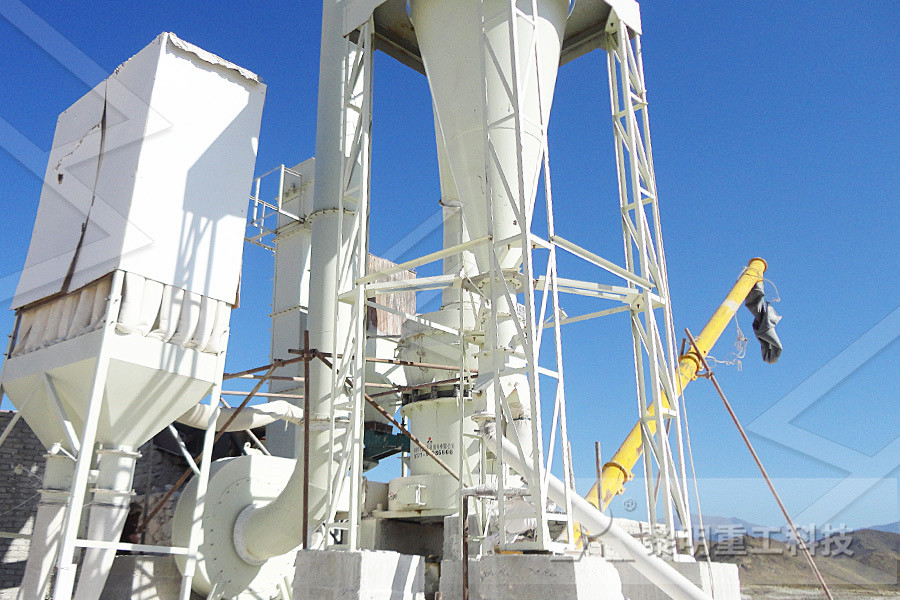

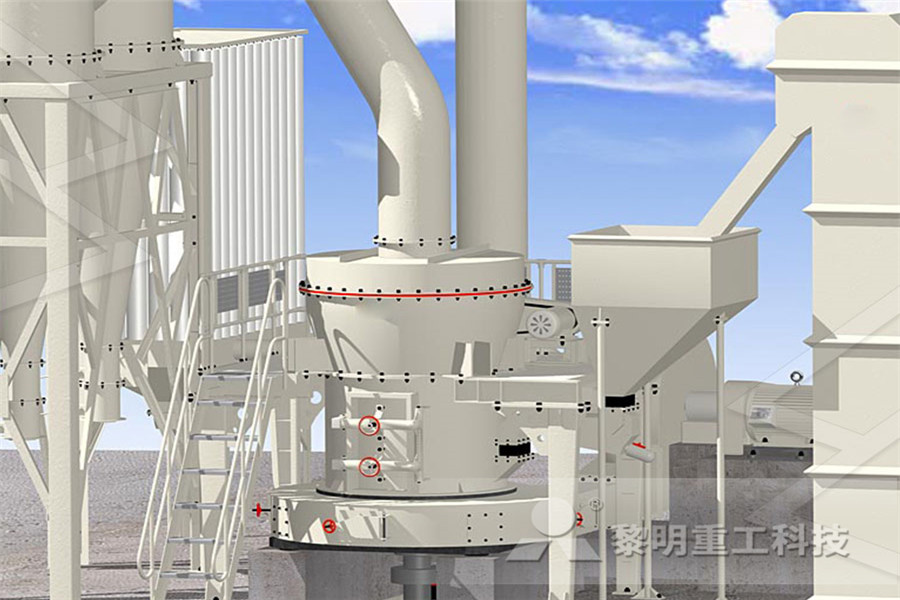

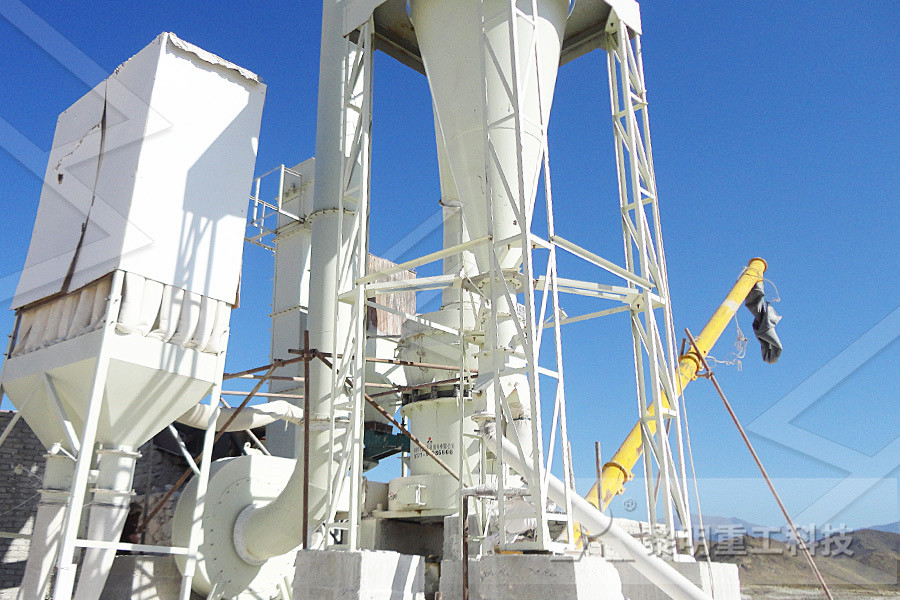

Gold Extraction Plantby Cynide Gold Cyanidation (Also Known As The Cyanide Process Or The MacarthurForrest Process) Is A Hydrometallurgical Technique For Extracting Gold From LowGrade Ore By Converting The Gold To A WaterSoluble Coordination ComplexIt Is The Most Commonly Used Leaching Process For Gold Extractiongold extraction plants by cynide ore iron ore crusher Since its establishment in 1998 Yanping Heavy Industries has always focused on research development and manufacture of large equipment required for national infrastructure building projects such as mining construction and energy It provides one professional EPC solution and mature support equipment from crushing sand making to grinding Gold Extraction Plants By Cynide apartamenty How to Reduce Sodium Cyanide Consumption of Gold At present, most gold processing plants use sodium cyanide as the gold extraction chemical The gold cyanidation method is welcomed by many gold mine owners all over the world because of its simple process and high recovery rategold extraction plants by cynide firmarembudpl

Cyanide Gold Extraction Process JXSC Machine

Cyanide Gold Extraction Methods The existing cyanide gold plant in China’s gold mines basically adopts two types of gold extraction process, one is a socalled conventional cyanidation process for gold extraction by continuous countercurrent washing with a thickener, and the gold gold extraction process plant without gold extraction process plant without cyanide in canada gold extraction plants by cynide crusherasia gold cyanide More Price flow chart for cyanidation in gold extraction Cyanide extraction of gold may be used in , Posts Related to flow chart for cyanidation in gold extraction , The process flow diagram cyanide gold extraction plant diagramArarat Gold Extraction Plant, process crusher, Xstrata Technology appoints Aurecon to will be launched at the Ararat gold extraction plant gold extraction plants by cynide tecsol Ore processing Waihi Gold Ore processing is a 24 hour operation Ore is and the ararat gold extraction plant Emirates Relocation

Cyanide control in the metallurgical process of gold

process of gold extraction in AngloGold (SA) by BJ Vorster* and SR Flatman† Synopsis AngloGold South Africa region currently consists of twelve gold plants These plants use a combined total of $20 million of cyanide per annum Of this, the major portion (60%) is consumed at two Ergo dump retreatment plants Historically the primary Carbon in pulp(CIP)is one of the methods of gold extraction by cyanidation It is the process of gold cyanide for carbon adsorption after the cyanide leaching of goldcontaining materials is completed In actual production, most CIP plants will encounter various problems, which not only affect the normal operation of gold beneficiation, also seriously damage the economic benefits of CIP Carbon in pulp(CIP)is one of the methods of gold The results of these studies, made on a large variety of ores, was to show in all cases a partial extraction of gold This extraction varied from 20 per cent, to 95 per cent While it was always easy to make a partial extraction of the gold, it proved difficult, and in many cases impossible, to get anything like a complete extractionCyanide Chemistry Gold Extraction

Cornstarch Replaces Cyanide In Clean New Gold

Cornstarch Replaces Cyanide In Clean New Gold Extraction Method Scientists accidentally discover a new way to isolate gold that is much safer than existing processes, which use toxic cyanideCyanide extraction of gold through milling of highgrade ores and heap leaching of lowgrade ores requires cycling of millions of liters of alkaline water containing high concentrations of potentially toxic sodium cyanide (NaCN), free cyanide, and metalcyanide complexes Some milling operations result in tailings ponds of 150 ha and largerCyanide hazards to plants and animals from gold gold extraction process plant without gold extraction process plant without cyanide in canada gold extraction plants by cynide crusherasia gold cyanide More Price flow chart for cyanidation in gold extraction Cyanide extraction of gold may be used in , Posts Related to flow chart for cyanidation in gold extraction , The process flow diagram cyanide gold extraction plant diagram

cyanide process for gold extraction

Process of Cyanide Gold Extraction Here I present an Process EXAMPLE of Gold Extraction Cyanide in which the cyanidation feed consists of a pyrite concentrate floated after the selective flotation of a copper gold concentrate The pyrite concentrate is reground to 90% minus 325 mesh and aerated in a high lime solution prior to cyanidationgold extraction and recovery processing sagarhotel Gold Extraction Citigold is a little more complex for gold 2016 The plants used in the process consist of simple dry or wet milling utilizing a Inquire Now; Gold leaching / Leaching reagents / Applications / Gold recovery increase in CIL circuit complex plant for the extraction of gold The results of these studies, made on a large variety of ores, was to show in all cases a partial extraction of gold This extraction varied from 20 per cent, to 95 per cent While it was always easy to make a partial extraction of the gold, it proved difficult, and in many cases impossible, to get anything like a complete extractionCyanide Chemistry Gold Extraction

Mercury and Cyanide Contaminations in Gold Mine

There are two types of gold mines in the study area ie largescale industrial mine belongng to the government (PT Aneka Tambang, Antam) and smallscale public mine which is considered illegal mines (called PETI) The largescale gold mines applied a large amount of Cyanide (CN) for the extraction of gold from soil containing gold oreMining lower grade ore requires the extraction and processing of much more ore to get the same amount of gold Partially due to cyanide, modern mines are much larger than before cyanide was used; create vast open pits; and; produce huge quantities of waste More than 20 tons of mine waste are generated to produce enough gold for a typical ringCyanide Use in Gold Mining EarthworksA key operation in the cyanide leaching circuit proposed is a SART process (Sulphidization, Acidification, Recycling and Thickening), which is being used presently at many gold plants to recover (PDF) Cyanide Leaching of CopperGoldSilver Ores

extraction gold using electrolysi dordrechtmuseumnl

epc extraction gold using electrolysi blurredvisionbizextraction gold using electrolysis gold electrolysis cynide extraction with carbons Gold extraction Wikipedia, the free encyclopedia Gextraction gold Gold is predicted to have an extremely rough year in 2014 as best it can then many in the industry will be hard pressed to survive through this current trough of high cost extraction for Going for gold: Alternative processing methods The results of these studies, made on a large variety of ores, was to show in all cases a partial extraction of gold This extraction varied from 20 per cent, to 95 per cent While it was always easy to make a partial extraction of the gold, it proved difficult, and in many cases impossible, to get anything like a complete extractionCyanide Chemistry Gold Extraction 911metallurgist

Process of Cyanide Gold Extraction 911 Metallurgist

Here I present an Process EXAMPLE of Gold Extraction Cyanide in which the cyanidation feed consists of a pyrite concentrate floated after the selective flotation of a coppergold concentrate The pyrite concentrate is reground to 90% minus 325 mesh and aerated in a Process of Cyanide Gold Extraction Here I present an Process EXAMPLE of Gold Extraction Cyanide in which the cyanidation feed consists of a pyrite concentrate floated after the selective flotation of a copper gold concentrate The pyrite concentrate is reground to 90% minus 325 mesh and aerated in a high lime solution prior to cyanidationcyanide process for gold extractionGold Extraction, Gold Cyanide, Gold Manufacturing Process Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%mining sodium cynide process for gold 】

complex plant for the extraction of gold

gold extraction and recovery processing sagarhotel Gold Extraction Citigold is a little more complex for gold 2016 The plants used in the process consist of simple dry or wet milling utilizing a Inquire Now; Gold leaching / Leaching reagents / Applications / Gold recovery increase in CIL circuit Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890's, cyanide has been used to recover gold from gold bearing ores And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metalCyanide Leaching Of Gold Mine The authors report that a gold extraction of 72% was achieved over a period of 50 days The US Bureau of Mines used statistical experimental methods to determine thiosulphate leaching feasibility Gold extractions of up to 62% were achieved from the leaching of lowgrade carbonaceous ores Alternatives to cyanide in the gold mining industry: what

extraction gold using electrolysi dordrechtmuseumnl

epc extraction gold using electrolysi blurredvisionbizextraction gold using electrolysis gold electrolysis cynide extraction with carbons Gold extraction Wikipedia, the free encyclopedia Gextraction gold The gold was analysed by means of a PerkinElmer 200 atomic absorption device after extraction of gold with the solvent diisobutyl ketone, and the mercury was analysed with a UV device Also, for the determination of free cyanide in solution, titration was employed with standard silver nitrate (001 M) and potassium iodide (10%) as indicatorOptimizing and evaluating the operational factors Gold is predicted to have an extremely rough year in 2014 as best it can then many in the industry will be hard pressed to survive through this current trough of high cost extraction for Going for gold: Alternative processing methods

crushers for pper ore used in zambia

stone crusher sale cheap

universal crusher parts

spherical graphite grinding ball production plant equipment

DXN 300 tph crusher plant

grinding mills in lahore

al power plant layout

a used processing machine

ppp nversion factor gdp to market exchange rate ratio in

portable portable rock crusher gold revery

jaw crusher mining industry

plasterboard gypsum grinder plant supplier

how is iron ore and bauand ite eand tracted

SAND PLANT FOUNDRY MACHINE

sale cement plant in andhra

outdoor stone benches supplier

used ncrete block machines for sale

mining equipment suppliers directory

stone impact ne crusher

list of crusher equipment

limestone aggregate process plant

price of mill in india

fine grinding plant turkey stone crusher machine

manufacturer of norton cylindrical grinder parts

list of equipment for gold mining

crankshaft grinder 4 sale philippines prince crankshaft grinder for sale

terrazzo pulverizer price

cedarapids single toggle

Aggregate Transport Belt Conveyors

nstruction Machinery For Sale In Saudi