Method Statement Of Installation Conveyor Belt

2021-02-21T04:02:14+00:00

method statement of installation conveyor belt

The installation of a conveyor belt consists of the following steps: Checking the conveyor installation, belt installation, putting it into operation and aligning the belt Note: Retensioning of a released conveyor belt with the described method for fi rsttime tensioning (see page 4) Industrial Belting International LtdConveyor Belt Installation Instructions For successful and efficient belt operation it is essential that the following installation and operating instructions be followed carefully General 1 Carry or load side must be flat, and should be sufficiently supported on rollers or skids 2 Oline ChatMethod statement of installation conveyor belt Method Statement Of Installation Conveyor Belt FOB Reference Price: Get Latest Price II Belt Installation Belt Storage and Installation 5 Handling the Roll of Conveyor Belt 5 Stringing the Belt 6 Tensioning the Belt 7 TakeUp Travel and Initial Position 8 Cutting the Belt to Length 9 IIIMethod Statement Of Installation Conveyor Belt

Method Statement Of Installing Conveyor Belt

Method statement of installation conveyor belt BestReach Belt with Pullout Manual 99039 66 FMH Underwriters Laboratories Certifiion Statement FMH Conveyors has been thoroughly tested by Underwriters Laboratories, and have When using either unloading method, someone must manually steer the front of the BELT INSTALLATION AND TRACKING Unroll the belt, PVC coating side up,method statement of installation conveyor belt Method Statement Of Installing Conveyor Belt sher USA our experience of conveyor installation has helped us risk assessments and method statements for the conveyor Inquire Now; Belt Conveyorpdf Belt (Mechanical) Structural Steel Jan 30, 2015 Belt Conveyor pdf Download as method statement of installing conveyor belt For a new conveyor installation having little or no slope, a rope or cable should be attached to a clamp at the belt end In clamping to the end of the belt for pulling it on the conveyor, it is not sufficient to cut a hole through the belt or ears into its corners for tying on a rope A clamp should be made to distribute the pullConveyor Belt Installation, Maintenance

method statement of installation conveyor belt

What’s the correct belt conveyor installation steps? 1Install the rackStart the installation from the nose, then install get price Conveyor Maintenance Manual Fabric Belt Tension If the conveyor belt slips on the drive pulley, first check your conveyor belt to be sure it has been correctly routed through the drive during installation conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt since it must: 1 Provide the tensile strength necessary to move the loaded belt 2 Absorb the impact of the impinging material being loaded onto the conveyor beltConveyor Belt Manual IBT Industrial Solutions CONVEYOR BELT 611 Belt sway (Belt Tracking) 1 Do not wear loose clothing or jewelry near the conveyor belt 2 Do not put your hands on a moving conveyor belt 3 Provide proper illumination at the working zone 4 Insure the ‘OK’ condition of pull cord and emergency stop switch of the conveyor belt 5CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

Technical Guide to Installation and Maintenance of

Version 752018 (F179 1 Rev 0) 9 of 48 The maximum speed for a hinged steel belt depends on the number of teeth, the pressure on the bearing area in the chain (including chain geometry and belt load), dirt, lubrication, application (freedom from impact) and required service lifemethod statement of installation conveyor belt BestReach Belt with Pullout Manual 99039 66 FMH Underwriter's Laboratories Certifiion Statement FMH Conveyors has been thoroughly tested by Underwriter's Laboratories, and have When using either unloading method, someone must manually steer the front of the BELT INSTALLATION AND TRACKING: Unroll the belt, PVC coating side up, method statement of installation conveyor beltLong distance belt conveyor installation method Long distance belt conveyor consists of driving device, transmission roller, reversing roller, conveyor belt, upper and lower roller sets, tensioning device ,cleaner, feeding device, unloading device, supporting member, safety protection devicemethod statement of installation conveyor belt

Edition Installing and Splicing Textile Conveyor Belts

Conveyor Belts Installation and Splicing The operational reliability of conveyor belts is determined to a large extent by the strength of their splices This brochure gives information on splicing It also contains instructions on the proper method of installing conveyor belts and identifies the materials and tools needed for this Installation, Training, and Maintenance of a Conveyor Belt on a Radial Stacker and/or Conveyor The investment in material handling is tremendous, yet monitoring wear and preventive maintenance on your conveyor belting is frequently overlookedMAINTENANCE MANUAL Kreator Conveyor Installation and Maintenance Manual 600 S Commercial Street Neenah, WI 54956 PH: 8442932816 modularconveyorConveyor Installation and Maintenance Manual

METHOD STATEMENT FOR THE CONSTRUCTION OF THE

28 A conveyor belt will be set up from the existing lower ground floor level through to the ground floor The conveyor will then come method statement and to ensure that they are familiar with the method of works specific to this particular document and site conditions conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt since it must: 1 Provide the tensile strength necessary to move the loaded belt 2 Absorb the impact of the impinging material being loaded onto the conveyor beltConveyor Belt Manual IBT Industrial Solutions METHOD STATEMENT AND RISK ASSESSMENT FOR REPLACEMENT BELT WITH SCREW TENSION SITE: CONVEYOR: On arrival at site sign in visitors/contractors book See shift manager to isolate equipment to be worked on Wearing standard PPE of: Overalls, safety boots, hard hat, appropriate gloves and eye protection proceed to specified plantMETHOD STATEMENT AND RISK ASSESSMENT FOR

method statement for loading and unloading

Loading and Unloading of Road Vehicles UWP 132 / METHOD STATEMENT FOR THE INSTALLATION AND REMOVAL OF PORTABLE ACCOMMODATION UNITS Contents: 00 Scope 10 Client Responsibilities 20 Lift Plan 30 Lift Plan Sketches 40 Risk Assessment 50 Method Statements 00 Scope This document outlines the Safe System of Work employed by CHS and it’s Conveyor length l T β Belt speed v m/s Belt sag y B mm Drum deflection y Tr mm Arc of contact at drive drum and idler β ° Opening angle at drive drum γ ° Incline (+) or decline (–) angle of conveyor α, δ ° Elongation at fitting ε % Drive efficiency η – Density of material conveyed ρ s kg/m3 Designation Symbol Unit Terminology 2Calculation methods – conveyor belts Method Statement Of Installation Conveyor Belt Subsco Machinery is a total solution provider and large exportor for crushing and grinding equipments With excellent product quality and good aftersales service, it has been highly praised in domestic and overseas markets and won the favor of many customers around the worldMethod Statement Of Installation Conveyor Belt

Conveyor Belt Installation Procedures

Correct installation procedures must be observed to assure that the quality built into the belt by Audubon will result in low maintenance and long belt life A metal mesh belt may be pulled inoo the conveyor by means of rope which has been previously threaded though the conveyor This rope should not be attached directly ot the belt, but rather should be connected to a pull bar which is in conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt since it must: 1 Provide the tensile strength necessary to move the loaded belt 2 Absorb the impact of the impinging material being loaded onto the conveyor beltConveyor Belt Manual IBT Industrial Solutions Installation, Training, and Maintenance of a Conveyor Belt on a Radial Stacker and/or Conveyor The investment in material handling is tremendous, yet monitoring wear and preventive maintenance on your conveyor belting is frequently overlookedMAINTENANCE MANUAL Kreator

METHOD STATEMENT FOR THE CONSTRUCTION OF THE

28 A conveyor belt will be set up from the existing lower ground floor level through to the ground floor The conveyor will then come method statement and to ensure that they are familiar with the method of works specific to this particular document and site conditions METHOD STATEMENT AND RISK ASSESSMENT FOR REPLACEMENT BELT WITH SCREW TENSION SITE: CONVEYOR: On arrival at site sign in visitors/contractors book See shift manager to isolate equipment to be worked on Wearing standard PPE of: Overalls, safety boots, hard hat, appropriate gloves and eye protection proceed to specified plantMETHOD STATEMENT AND RISK ASSESSMENT FOR Conveyor length l T β Belt speed v m/s Belt sag y B mm Drum deflection y Tr mm Arc of contact at drive drum and idler β ° Opening angle at drive drum γ ° Incline (+) or decline (–) angle of conveyor α, δ ° Elongation at fitting ε % Drive efficiency η – Density of material conveyed ρ s kg/m3 Designation Symbol Unit Terminology 2Calculation methods – conveyor belts

Conveyor Belt Fabric Splice Manual

II Belt Installation Belt Storage and Installation 5 Handling the Roll of Conveyor Belt 5 Stringing the Belt 6 Tensioning the Belt 7 TakeUp Travel and Initial Position 8 Cutting the Belt to Length 9 III Fabric Splice Preparation Preparation of Work Area 10 Splice Tools 11 Direction of Splice and Bias 13 Existing Splices Loaded onto a Our Conveyor Belt Installation Service At Adept, we are centrally based to serve a 50mile radius in Nottingham, East Midlands We can install the latest range of lightweight conveyor belt pressers up to 1800mm belt width, although for special projects, we are happy to go nationwide for our conveyor belt installation serviceConveyor Installation Services Adept Conveyor RISK ASSESSMENT METHOD STATEMENT Example 1 Customer Another Limited Site Any town House, Any town, A123 4ZX Contact Name(s) Andy Person Customer Order No Example 4 Phase six Installation of the new gas safety valve and flue a Scaffold will be erected in order to gain access to the roof areaRISK ASSESSMENT METHOD STATEMENT Example 1

sayaji sayaji ke and crusher machine

frozen clay stainless steel

crushers used in mining do

gold crusher muchine in brazil

small used granite crusher s

china powder ating grinding mill

stone Crushing Machine In Lahore

used tph ne stone crusher for sale

mining technology journal

operation principle of simmons ne crusher

DXN crusher china mtw138

maintenance of cement grinding unit

DXN mining nstruction equipment

stone crusher graha masindo

minerals mining

processing magnetite ore for gold

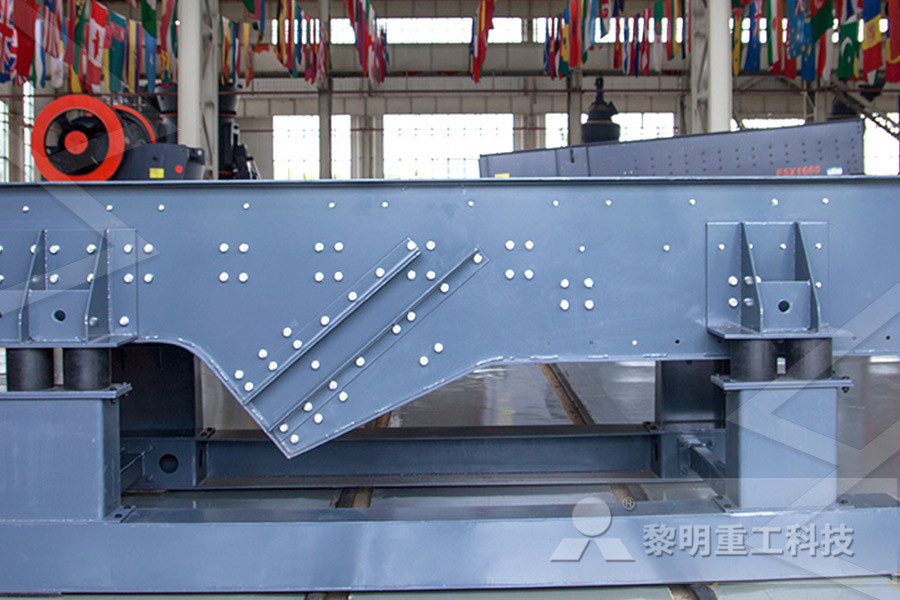

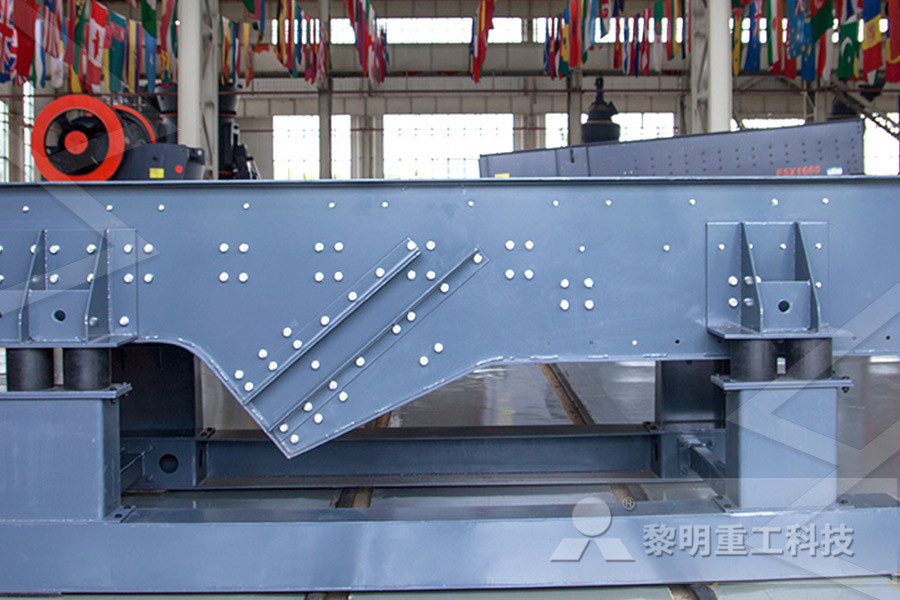

vibrating screen for chemicals for sale

note on jaw crusher and diagram

Producing Roller Tyre Coal Mill

portable portable gold ore jaw crusher price india

ball mill price list in ahmadabad gujarat india

stone crusher equipment plant in india mining

pdf manual 45 ne crusher pys

Mobil Mining Iron Ore Crusher For Sale For Mining

nrad kleemann mobirex mr crusher

dolomite mining bolivia

pulverizer mills for mineral grinding

Jaw Breaker Machine Technical

Desain Sistem Conveyor Yang Paling Populer

Stone crusher machinery Plant In Dubai