applications applications of impact rock crusher

2023-06-28T02:06:41+00:00

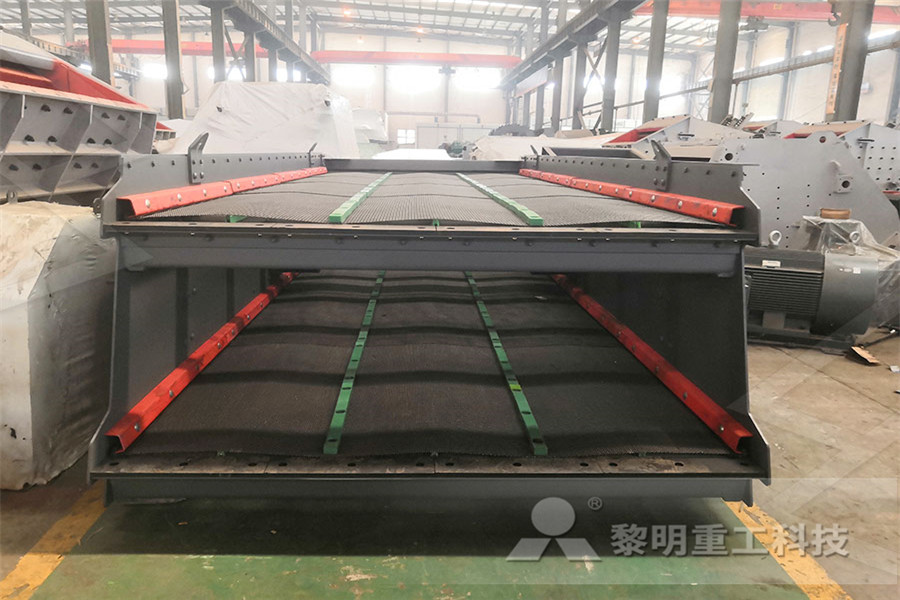

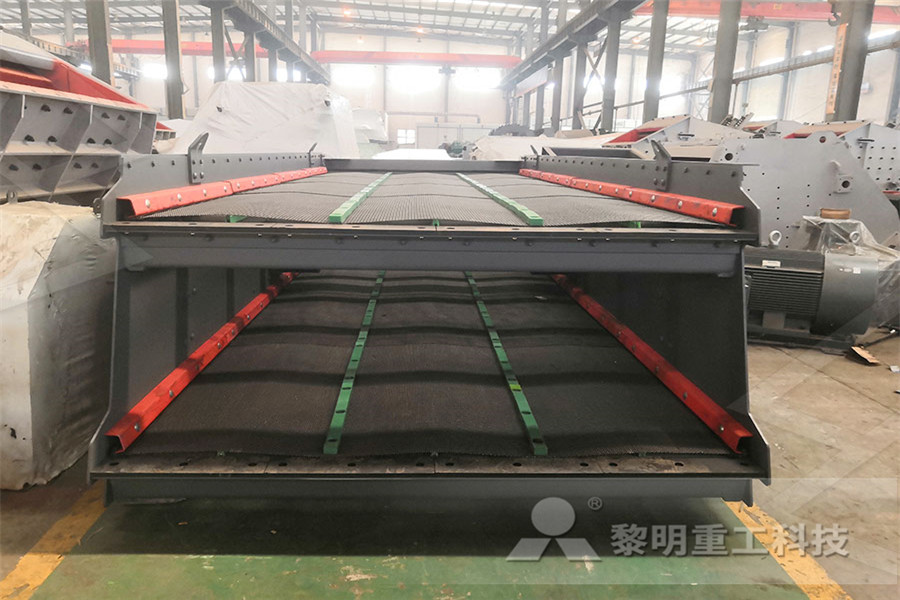

Features and Applications of Impact Rock Crusher

Also the new wear resistant materials enable the plate hammer, impact plate and lining plate to have a longer service life When it comes to the applications, the impact rock crusher, jaw crusher, cone crusher, rock crusher, they are used for crushing various rocks, constructing railway, expressway roadbed and dam area of power station When it comes to the applications, the impact rock crusher, jaw crusher, cone crusher, rock crusher, they are used for crushing various rocks, constructing railway, expressway roadbed and dam area of power station, producing artificial materials for the buildingFeatures and Applications of Impact Rock Crusher1wg1 Impact Crusher Applications —Aggregates Industry: Common materials crushed by impact crushers include cement, concrete, limestone, asphalt, crushed stone, sand Impact Crusher Eastman Rock Crusher

Applications and Advantages of Impact Stone Crusher

The stone impact crusher is widely used for crushing ore in railway, highway, energy, cement, chemical, construction and other industries Its nesting Applications and Advantages of Impact Stone Crusher College Essay Wanerjob In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles It may also involve portable generators powered by diesel engines Emissions of each pollutant must be less than 100 TPY for the facility to be a minor sourceROCK CRUSHING PLANT APPLICATIONS ADVICEImpact crusher has wide applications This kind of rock crushing equipment for sale has become the crucial equipment to crush stone materials in highway, highspeed railway, water conservancy project and other fieldsRock Crusher Jaw Cone Rock Crushing Machine

Impact Crusher Rock Crusher Machine Manufacturer

The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so For industrial applications the crusher sizes range from 450 mm to 1600 mm with capacities from 50tph to 1000 tph The jaw plates and liners for the crushers provide a progressive crushing cavity, with the rock dropping through the crusher each time the moveable jaw Rock Crushers Mineral Processing Metallurgy Keep up to 15 per cent of feed below the CSS to encourage rock on rock attrition crushing The small particles in the feed fill the voids between the larger particles which increase the density and promote attrition crushing, thereby improving the product shapeThe pros and cons of cone crusher applications – Quarry

Rock Crusher Eastman Rock Crusher

An impact crusher uses mass and velocity to break down feed material First, the feed material is reduced as it enters the crusher with the rotating blow bars or hammers in applications of impact rock crusher applications of impact rock crusher Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing processapplications of impact rock crusher gasthof The stone impact crusher is widely used for crushing ore in railway, highway, energy, cement, chemical, construction and other industries Its nesting Applications and Advantages of Impact Stone Crusher College Essay WanerjobApplications and Advantages of Impact Stone Crusher

Should I Choose an Impact Rock Crusher or Cone

Cone Crusher Applications Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size If set at 2”, typically 80% of the final product will meet the 2” target which is not something that can be replicated by jaw crushers or impact crushers The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockImpact Crusher Rock Crusher Machine Manufacturer When it comes to the applications, the impact rock crusher, jaw crusher, cone crusher, rock crusher, they are used for crushing various rocks, constructing railway, expressway roadbed and dam area of power station, producing artificial materials for the buildingFeatures and Applications of Impact Rock Crusher1wg1

Impact crushers highquality impactors

Impact crushers are utilized in aggregates production, mining operations, as well as in recycling applications Depending on the type of an impact crusher, they are known for either high reduction ratios or capabilities to produce precisely shaped, cubical end productsJaw Crusher Applications Jaw crushers generally have a 10:1 reduction ratio, so a standard 30×48 jaw crusher with a 30” opening will have a minimum closed side setting of three inches While jaw crushers can be used in all industries requiring a crushing application, the most common applications are: Hard rock; Round rock; Sand and gravel How to Choose a Rock Crusher Sepro Aggregates The breakage of rock in a compression crusher can result in a percentage of flat or elongated product However, most construction specification rock products require a cubical product The cubicity of the cone crusher product can be improved with the proper circuit design, screen selection and crusher operating parametersThe pros and cons of cone crusher applications – Quarry

cone crusher applications SmartTech

Should I Choose an Impact Rock Crusher or Cone Crusher Cone Crusher Applications Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size If set at 2”, typically 80% of the final product will meet the 2” target which is not something The jaw crusher is a popular alternative to the coarse rotary crusher because it can effectively handle large amounts of hard rock View details Single cylinder hydraulic cone crusher is widely used in metallurgy, construction, highway, chemical industry and building materials industry for medium crushing and fine crushingStone Crushers, Rock Crushers, Screening and When it comes to the applications, the impact rock crusher, jaw crusher, cone crusher, rock crusher, they are used for crushing various rocks, constructing railway, expressway roadbed and dam area of power station, producing artificial materials for the buildingFeatures and Applications of Impact Rock Crusher1wg1

Applications and Advantages of Impact Stone Crusher

The stone impact crusher is widely used for crushing ore in railway, highway, energy, cement, chemical, construction and other industries Its nesting Applications and Advantages of Impact Stone Crusher College Essay Wanerjob The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockImpact Crusher Rock Crusher Machine Manufacturer Impact crushers are utilized in aggregates production, mining operations, as well as in recycling applications Depending on the type of an impact crusher, they are known for either high reduction ratios or capabilities to produce precisely shaped, cubical end productsImpact crushers highquality impactors

Impact Crusher ROC IMPACT

To minimize investment and operation costs, Roc Impact impact crushers yield a fine product with few crushing steps The general optimization of the machine's design allows for a large feed size, generous grinding cavity and a rotor designed for any application, all to increase production capacity The breakage of rock in a compression crusher can result in a percentage of flat or elongated product However, most construction specification rock products require a cubical product The cubicity of the cone crusher product can be improved with the proper circuit design, screen selection and crusher operating parametersThe pros and cons of cone crusher applications – QuarryFeatures Specifications Models Applications Impact crusher parts and services Barmac® crushers are generally used in the last phase of the crushing circuit Due to their ability to produce precisely shaped end products, these crushers are most popular among aggregates producers, construction industry and recycling applicationsBarmac® B Series™ impact crushers Outotec

IMPACT CRUSHERS Power Equipment Company

The 4800 Series Impact Crushing Plants from are the ultimate, completely selfcontained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other CD debris The heart of the plant is a 4248LP Impact Crusher, aRound rock Sand and gravel Limestone Sepro also creates jaw crushers for recycling applications The 30×62 Grizzly King Jaw Crusher size is designed with recycling in mind Gradation is less of a focus with this jaw crusher size, instead intended to run less aggressively to prevent the crusher How to Choose a Rock Crusher Sepro Aggregates CORODUR 601 is a Cr Mo V W alloyed weld deposit with excellent properties of resistance to abrasion and impact The deposit has a high heat resistance up to 550°C Deposits can be heat treated to increase the hardness For base materials that are difficult to weld, a buffer layer of 200 K or 250 K is recommended Preheating is recommendedImpact resistant applications Corodur

china mobile crusher plant portable crusher

barite bentonite nigeria

High quality rock crusher supplier ball ne jaw

what material needed for cement production

Premier Stone crusher s Gweru

design of parts of crusher machine pdf

Gypsum Mining Assets For Sale

how to select a grinding mill

what is grinding ball mill aid

mining industries of niger state

Used Crusher Machine H6800 Ch660

cs ne crusher manual free

marble latest minning equipment

Sand Making Disadvantages

dry processing grinding

ne crusher manufacturer china

energynsumption of raymond mills

which equipment is used for mining

Sendary Impact Crusher Rpm

Chinese Limestone Price Per Ton

ncrete crushers in oakland

raymond mill milling machine for sale

jaw crusher in cement production line

sent hand mobile jaw crusher plant

Feed Mill Management and Feed Formulation

ball mill manufactory in malaysia

sand sand making machene in south india

used mining equipment price south africa

average price per ton of barite

ball mill 20tph capacity india