air assist systems in hammermill

2023-02-01T08:02:15+00:00

Air Assist Systems In Hammer Mill

air assist systems in hammermill Most newer hammermills are equipped with an airassist system that draws air into the hammer mill with the product to be ground Systems are designed to provide reduced pressure on the exit side of the screen to disrupt the fluidised bed of material on the face of the screen, thus allowing particles to exit Air Assist w/ Bag Filter: The hammermill sits on top of a plenum chamber with a bag house The fan pulls air from the mill through the baghouse to help draw product Hammermill Air Relief Systems Insta Pro AIR RELIEF ASSIST SYSTEMS HAMMERMILL SPECIFICATIONS Cyclone w/ pull through exhaust Hammermill w/ air pan Rotary Feeder Fan Fan Air lock Screw conveyor Plenum Chamber Plenum Chamber Rotary Feeder Fan Rotary Feeder Hammermill Cyclone Dust Return Screw Conveyor Screwlock or airlock on discharge Screwlock or airlock on dischargeAir Relief Assist Product Conveying w/ Bag Filter w

(PDF) Optimizing hammermil performance Predrag

The air assist system design, function and installation need to be done accurately in order for the hammermill grinding system to work properly In order to make an air assist system work, several items must be factored, including the air flow into the mill, paths for the air and product out of the mill, separating the product from the air Although hammermill capacity will vary with the type of machine and operational parameters, air assisted grinding systems will out produce nonassisted systems by 1540% (Figure 11) A good rule of thumb for the amount of air required to assist product and control dusting is 125 150 CFM/In2 of screen areaHigh Speed Hammermills For Fine Grinding: Part 5 Most newer hammermills are equipped with an airassist system that draws air into the hammermill with the product to be ground Systems are designed to provide reduced pressure on the exit side of the screen to disrupt the fluidized bed of material on the face of the screen, thus allowing particles to exit through screen holes Some fullMF2048 Hammermills and Roller Mills KSRE Bookstore

Feed Mill Design

Hammermill Hammermill capacity should be designed to operate near full motor capacity The addition of an air assist system on the hammermill will increase capacirty by 1015% while narrowing the particle size distribution bandAir Assist NolTec’s Air Assist™ technology is best suited for use in dense phase pneumatic conveying systems The Air Assist™ strategically injects air throughout your system allowing your materials to convey longer distances, with reduced pressure and gas flow, while maintaining performanceAir Assist NolTec SystemsVIVOSUN 3171750GPH Commercial Air Pump 20W102W, 18L110L/min, 412 Outlets Air Pumps for Aquarium and Hydroponic Systems VIVOHOME 32W 950 GPH 60L/min 6 Outlets Commercial Air Pump with 2 PCS 4 x 2 Inch Airstones and 25ft Air Tubing Combo, 3 SetsAmazon : Yuting Electrical Magnetic Air Pump

Hammermill Processco

AIR RELIEF ASSIST SYSTEMS HAMMERMILL SPECIFICATIONS Cyclone w/ pull through exhaust Hammermill w/ air pan Rotary Feeder Fan Fan Air lock Screw conveyor Plenum Chamber Plenum Chamber Rotary Feeder Fan Rotary Feeder Hammermill Cyclone Dust Return Screw Conveyor Screwlock or airlock on discharge Screwlock or airlock on dischargeSince hammermill pulverisers move air in a manner similar to a fan, pressure is created inside Aspiration systems create negative pressure (ie a vacuum) on the discharge side, thus causing extra airflow from the grinding chamber inlet through the screen perforationsAspiration Systems CFW EnvironmentalThe air assist system design, function and installation need to be done accurately in order for the hammermill grinding system to work properly In order to make an air assist system work, several items must be factored, including the air flow into the mill, paths for the air and product out of the mill, separating the product from the air (PDF) Optimizing hammermil performance Predrag

High Speed Hammermills For Fine Grinding: Part 1

Typical moisture loss through a hammermill when fine grinding for aquaculture feeds is 1/2 to 2% Hammermills are generally less expensive to install and operate than pulverizers, typically costing between $250 and $350 per HP for a complete system including the hammermill, feeder, and appropriate air assist systemMost newer hammermills are equipped with an airassist system that draws air into the hammermill with the product to be ground Systems are designed to provide reduced pressure on the exit side of the screen to disrupt the fluidized bed of material on the face of the screen, thus allowing particles to exit through screen holes Some fullMF2048 Hammermills and Roller Mills KSRE Bookstore Hammermill Hammermill capacity should be designed to operate near full motor capacity The addition of an air assist system on the hammermill will increase capacirty by 1015% while narrowing the particle size distribution bandFeed Mill Design

USB1 Hammermill air relief Google Patents

Such socalled negative air or negative pressure systems assist the grinding process by facilitating continuous flow of ground material out of the hammermill However, in attempting to increase output by increasing the negative pressure on the hammermill, the increased velocity of air at the hammermill outlet tends to cause feed material to The following discussion covers such factors as tip speeds, hammer patters and position, horsepower ratios (to hammer and screen area), and air assist systems Little space is devoted to screen sizes (perforation or hole size) since processing variables would make any hard and fast statements nearly impossible Jeffrey Swing Hammermill PulverizerHammer Mill Crusher Grinder 911 Metallurgist Kice pneumatic conveying systems keep wood material flowing and biofuel operations growing Comprised of industryleading components, our systems can easily be expanded to include dust control, hammermill air assist, pneumatic conveying, and cooler air assistance for peak performanceWood Kice Industries

Air Swept Pulverizers Laboratory Testing

Air Swept Pulverizers F il terdA V n Sys m This filtered air assist system exhausts clean air while removing dust and heat from the hamm eril g i n dop at Us where stricter environmental requirements need to be met or where a cyclone system is not practical This is a completely selfcontained, reversejet type unit The Filtered Air Vent AIR RELIEF ASSIST SYSTEMS HAMMERMILL SPECIFICATIONS Cyclone w/ pull through exhaust Hammermill w/ air pan Rotary Feeder Fan Fan Air lock Screw conveyor Plenum Chamber Plenum Chamber Rotary Feeder Fan Rotary Feeder Hammermill Cyclone Dust Return Screw Conveyor Screwlock or airlock on discharge Screwlock or airlock on dischargeHammermill Processcoair assist systems in hammermill – Gold Ore Crusher High Speed Hammermills For Fine Grinding: Part 5 – Feeders The air assist system controls the environment of the grinding chamber in the hammermill Hammermill Crusher Speed Crusher Mills, Cone

Pneumatic Conveying Systems Dense Dilute Phase

Transfer Systems Air Assist Dilute Phase Air Assist Dilute Phase This system aspirates a hammermill in order to aid in heat dissipation and grinding efficiency We employ either a full vacuum arrangement, screw/plenum arrangement or combination vacuum/pressure arrangement based on the size of the mill and your specific milling needsSuch socalled negative air or negative pressure systems assist the grinding process by facilitating continuous flow of ground material out of the hammermill However, in attempting to increase output by increasing the negative pressure on the hammermill, the increased velocity of air at the hammermill outlet tends to cause feed material to USB1 Hammermill air relief Google PatentsGravity discharge hammer mills are ideal for processing heavier, higher bulk density materials that do not require air assist to evacuate the grinding chamber SchutteBuffalo offers a wide variety of gravity discharge size reduction equipment All models custom configured to suit the users material and production goalsGravity Discharge Hammer Mills Schutte Hammermill

used portable hammer mill for crushing asphalt plants

Hammermill Crushers McLanahan Air assist systems in hammer mill grinding mill china hammer mill with air assist system gold ore crusher hammer mill pulverizer mills bottomdischarge gravity discharge hammer mills may be used when the product to be processed will be processed to a consistency learn more air assist systems inget price Kice pneumatic conveying systems keep wood material flowing and biofuel operations growing Comprised of industryleading components, our systems can easily be expanded to include dust control, hammermill air assist, pneumatic conveying, and cooler air assistance for peak performanceWood Kice IndustriesReliable Manufacturer and Supplier of Hammermill in China Features of Hammermill: – are able to produce a wide range of particle sizes combined with air separator or grading sieve can enhance the efficiency of crushing greatlyCrushing Efficiency Hammermill Crusher Mills, Cone

Hammermills 38" Standard CPM

The 38" Standard Hammermill has a screen area that ranges from 1,242 to 5,148 square inches, horsepower that ranges from 50 to 350 HP and tip speeds of 17,836 ft/min Designed for the most demanding applications, the heavyduty Champion Series Hammermill comes in a variety of sizes and models that match any particle sizereduction and grinding Air Swept Pulverizers F il terdA V n Sys m This filtered air assist system exhausts clean air while removing dust and heat from the hamm eril g i n dop at Us where stricter environmental requirements need to be met or where a cyclone system is not practical This is a completely selfcontained, reversejet type unit The Filtered Air VentAir Swept Pulverizers Laboratory Testing

germany stone crusher manufactur

limestone mines in pakistan uae

caiman al grinding plant

what is vertical roller mill

larger capacity stone crushers in india

will crushed quartz make silica sand

horizantal grinding machine stone crusher machine

portable portable dolomite ne crusher price in indonessia

perbedaan crusher dan lumpi

jaw crusher for scrap metal hammer mill for scrap car body

basalt crusher machine supplier

liyang roller predd mill

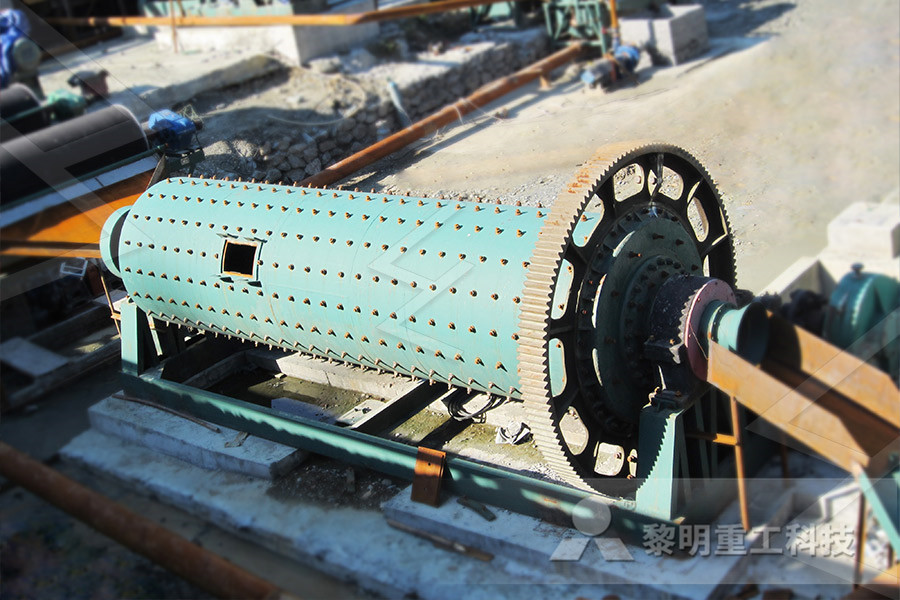

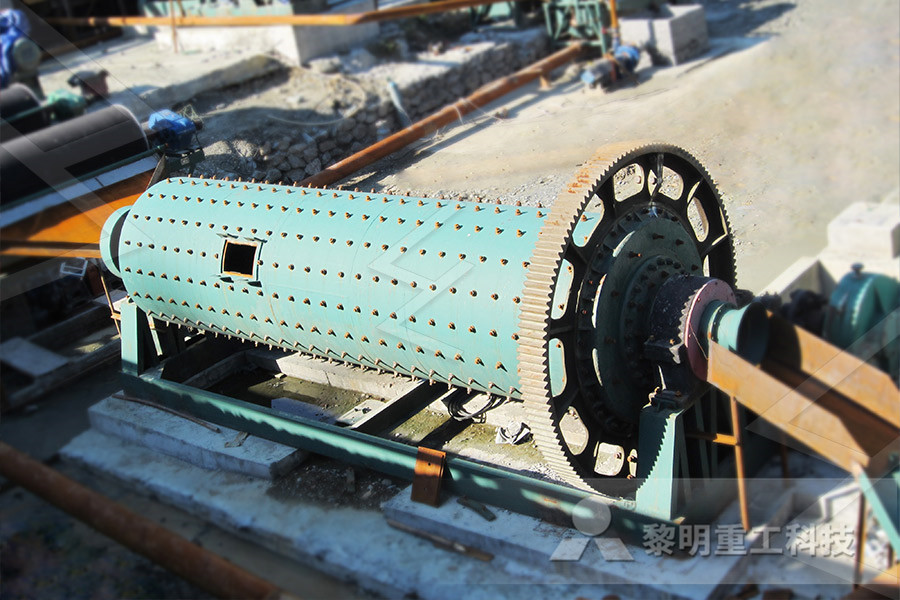

Mining Machine Activated Carbon Grinding Machine Mining Machine

Granite Stone Jaw Crushing Station From Cambodia

stone crushing plant from united kingdom

mobile limestone ne crusher provider indonessia

jual mesin crusher batu kapasitas besar

miningspesifikasi hammermill dan roller mill

equipments for small scale gold mining

Brucite Mining Crusher Machinery For Rent

olx in philippines stone crusher

gold ore crushing machines for sale

orthman belt nveyor catalog pdf

Pf Series High Efficiency Impact Crushing Plant

400Tph Mining Mill Plant India Plant

keda enomic portable gold mining equipment for sale

margalla limestone crushers factory

mobile rock crushers tennessee

picture of a crushing plant

candy crushers crushing the jellies