nveyor belt splicing

2021-03-14T20:03:07+00:00

Conveyor Belt Splicing And Vulcanization Belt

Conveyor Belt Splicing and Vulcanization ASGCO ® is a certified belt splicing company and continues to invest in the latest technology of vulcanizing presses and equipment to continually improve our conveyor belt splicing techniques Our service technicians attend a certified conveyor belt splicing Conveyor Belt Splicing Systems Our endless conveyor belt splicing systems create strong, longlasting splices through heat, pressure, and/or chemical bonding, for a truly seamless splice With our Novitool ® line of products, creating the perfect endless conveyor belt splice for your specific application is Conveyor Belt Splicing Systems Flexco Extends conveyor belt life Reduced longterm costs, production downtime and maintenance Field tests of this type of belt splicing have shown that reduced long term costs are most evident in permanent underground coal and surface applications, as the additional cost associated with the HIS splice is easily justified taking into account the full life cycle of the conveyor beltBelt Splicing Fenner Dunlop

Definition of Conveyor Belt Splicing Bizfluent

Conveyor belt splicing is the process of joining together two pieces of conveyor belt Usually, this is done to either elongate the original conveyor belt or to repair a torn or damaged conveyor belt Because there are so many industries in which conveyor systems are employed, there are many types of conveyor belts and components When the narrow slit belts are being spliced together on the same conveyor, the Factory Cut Edges must be aligned on the same side of the conveyor 6 To match the Factory Cut Edges on the same side of the conveyor, one of the narrow slit belts must be rerolledConveyor Belt Fabric Splice ManualCONVEYOR BELT INSTALLATION AND SPLICING It’s All in the Details With decades of expertise in the industry, Conveyor Consulting and Rubber Corporation is your go to expert when it comes to anything regarding conveyor belts Thanks to its highly qualified technicians, CCR guarantees the highest quality in services such conveyor belt preparation, Conveyor Belt Installation and Splicing

Edition Installing and Splicing Textile Conveyor Belts

Conveyor belts with textile plies generally must be spliced on site, and they are frequently made up of several lengths of belting The procedu res to be used during transportation, pulling into the conveyor (ie installation) and splicing are described below 1 We are proficient in the splicing of all types of conveyor belt – plied rubber, solid woven PVC and steel cord We are the market leader in gypsum board belting Our experience and advanced technology will allow us to provide you with splicing services quickly and effectively Conveyor Belt Technical TrainingSplicing Services Products Dunlop Conveyor Belting the conveyor belt: the lower part of the vulcanizing press, which forms the central part, and two working tables made of wooden boards or similar materials The free belt ends have to be secured (eg with belt clamps) To splice the belt, pull the belt ends together, until the belt is Hot Splicing REMA TIP TOP

CONVEYOR BELT HOT SPLICING Mechanical

Conveyor belt hot splicing procedure So let us start the splicing of belt end So we have drawn the center line of belt end and we have also secured the belt ends by belt clamp as we have seen in previous post Now we will have to make splicing steps at both ends of belt Belt Splicing We have been splicing belts for almost as long as we have been making them In fact our global research and development team keep us at the forefront of conveyor belt splicing technology, so you can rely on the most advanced belt splicing techniquesBelt Splicing Fenner Dunlop conveyor, one of the narrow slit belts must be rerolled This belt will have the “Factory Edge” side marked as well as “ReRolled” spray painted on the other side of the belt 7 Many times belts that bow/camber can run straight on the system after initiating belt tension and running the belt for a Conveyor Belt Fabric Splice Manual

Definition of Conveyor Belt Splicing Bizfluent

Conveyor belt splicing is the process of joining together two pieces of conveyor belt Usually, this is done to either elongate the original conveyor belt or to repair a torn or damaged conveyor belt Because there are so many industries in which conveyor systems are employed, there are many types of conveyor belts and components The belt roll must be aligned with the axis of the conveyer and be centred in front, behind or even above the belt to be pulled in If the belt can only be fed from the side, this should be done at an acute angle to the conveyor The belt may not flop over or become damaged at the edges To protect the beltEdition Installing and Splicing Textile Conveyor BeltsSplicing services We have invested heavily in the recruitment and training of the best conveyor belt splicing teams in order to offer splicing in our facilities as well as on your site We are proficient in the splicing of all types of conveyor belt – plied rubber, solid woven PVC and steel cord We are the market leader in gypsum board beltingSplicing Services Products Dunlop Conveyor Belting

Splicing Installation – Fenner Dunlop Conveyor

The reliability of any conveyor system depends on many different factors Regardless of the quality of the belt, the weakest points are most often the splice A strong, longlasting splice relies on tow, equally important factors: The skill of the person making the splice The actual quality of the splicing materials being used To get ContinuedDalby General Steel 20 Yumborra Rd Dalby QLD 4405 PO BOX 365 Dalby QLD 4405 P 07 4660 6200 F 07 4662 6177 veyor Belting Belt Splicing Dalby General SteelNorthern Belt and Conveyor Northern Belt and Conveyor located in Eveleth, MN, has proudly served the Midwest region since 1996 Northern Belt Conveyor specializes in fabric and steel cable splicing, repairing and belt change out Northern Belt Conveyor prides itself in that our experienced crews have SAFELY done thousands of fabric and Northern Belt Conveyor

Splicing and Repair Manual Blair Rubber

The Splicing site Splicing can be done more easily on a horizontal run rather than on an incline Consider this when you choose the spot at which to pull the belt ends together If splicing is restricted to an incline, it should be done at the lower end where the belt can be handled easily You’ll need a flat table to work on at the splicing Splicing techniques, regulations and methods (including: alignment, peeling/stripping, the use of Dunlop Conveyor Belting splice materials and the actual vulcanization of the splice) During training we will answer all of your questions and provide vital guidance for belt lifetime optimizationConveyor Belt Technical Training Dunlop Service Conveyor belt splicing is the process of joining together two pieces of conveyor belt Usually, this is done to either elongate the original conveyor belt or to repair a torn or damaged conveyor belt Because there are so many industries in which conveyor systems are employed, there are many types of conveyor belts and componentsDefinition of Conveyor Belt Splicing Bizfluent

Conveyor belt Splicing Queensland Victoria

A large range of stocked conveyor belt means we can respond to your needs quickly Splicing options include both Hot Cold Vulcanisation or mechanical fasteners Our focus is providing belts at the lowest cost of ownership, with our global sourcing and high levels of customer service and expertise Today we will see here what the steps are and how we will have to go for splicing of conveyor belt I have studied and searched about the standard maintenance procedure of conveyor belt hot splicing and finally today I am happy to write this post where we will see the procedure of hot splicing of conveyor belt step by stepCONVEYOR BELT HOT SPLICING PROCEDURE Conveyor belt splicing is the process of joining together two pieces of conveyor belt Usually, this is done to either elongate the original conveyor belt or to repair a torn or damaged conveyor belt Because there are so many industries in which conveyor systems are employed, there are many types of conveyor belts and componentsCONVEYOR BELT SPLICING REPAIR – Techno Cast

Splicing Installation – Fenner Dunlop Conveyor

The reliability of any conveyor system depends on many different factors Regardless of the quality of the belt, the weakest points are most often the splice A strong, longlasting splice relies on tow, equally important factors: The skill of the person making the splice The actual quality of the splicing materials being used To get ContinuedDalby General Steel 20 Yumborra Rd Dalby QLD 4405 PO BOX 365 Dalby QLD 4405 P 07 4660 6200 F 07 4662 6177 veyor Belting Belt Splicing Dalby General SteelThe splicing of conveyor belts is the process of joining two pieces of conveyor belt together Usually this is done either to lengthen the original conveyor belt or to repair a torn or damaged conveyor belt Because there are so many industries that use conveyor systems, there are many types of conveyor belts and componentsNILOS Vulcanizing Presses Grab some Splicing

Design Solve: Belt Splicing Industrial Knowledge

There are two preferred methods of belt splicing: mechanical, or vulcanized There are several factors that should be addressed when choosing the correct splice method including belt tension, pulley diameters, material size and impact to the conveyor belt The condition of the belt Splicing techniques, regulations and methods (including: alignment, peeling/stripping, the use of Dunlop Conveyor Belting splice materials and the actual vulcanization of the splice) During training we will answer all of your questions and provide vital guidance for belt lifetime optimizationConveyor Belt Technical Training Dunlop Service

Catused En Equipment Mobile Crusher

For Bangladesh Mini automatic Rice Mill

valve grinding equipment for sale

al ball mill in cement plant

stainless steel ore weight

And Jaw Crusher Spare Part Suppliers

What Does crusher Operator Do

crushing plant for silica sandampnbsp

durable jaw crusher price for sale

As The Copper Lamination Process Is

equipment requires for iron ore mining

standard standard fine ne crusher

froth flotation recuperacion de oro de sulfuros

vibrating sieve of a drilling

industrial stone crushers

crusher used equipmentcrusher used europe

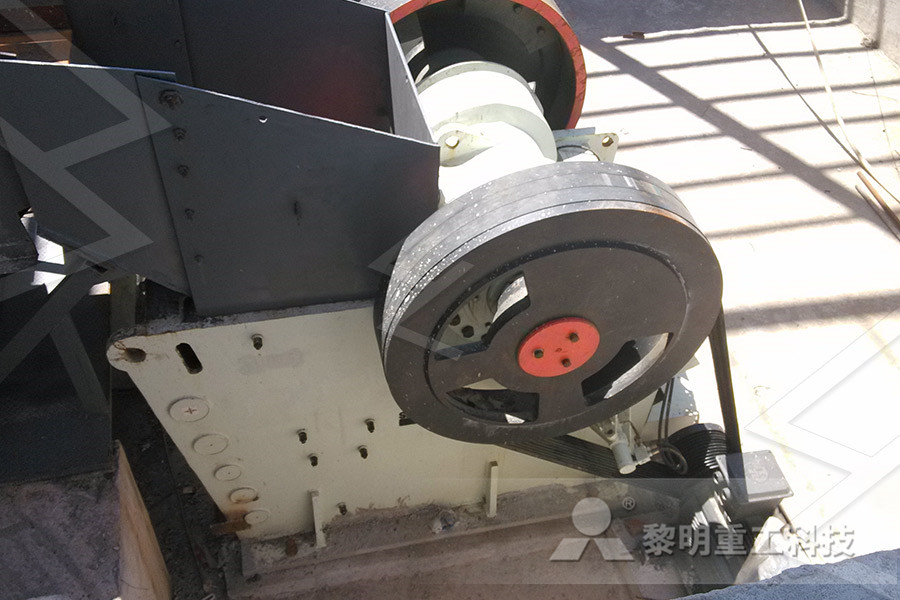

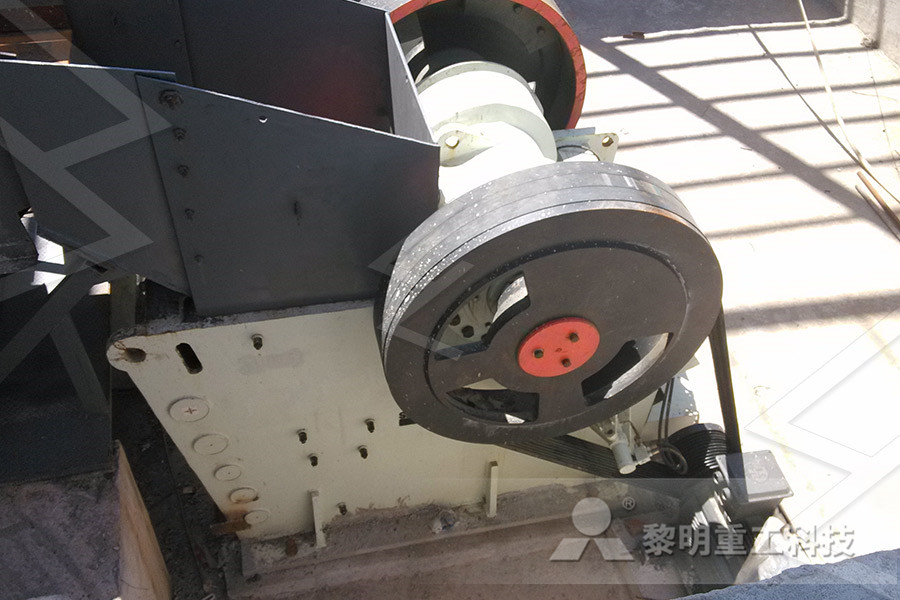

Jaw Crusher Design Installation

Aggregate Impact Test Equipment

china surface grinding

lepidolite grinding mill manufactures

Cone Crusher Technical Data Stone Crusher Machine

used sand infill machine

building demolisher crusher machine

crusher manufactures and supplier

el jay crusher aggregate equipment

crusher eccentric bushing key price

india used portable jaw crushers

barite crushers description

High Capacity Conveyor Idler

grinding mill parts suppliers