Feed Size Of Iron To Iron Ball Mill

2020-02-28T19:02:01+00:00

iron ore ball mill sizing winidurpl

feed size of iron ore to ball mill Iron Ore Ball Mill Processthpamitola Iron Ore Ball Mill Process Pdf Size Reduction By Grinding Methods Ball mills are used for wet grinding iron ore g oldcopper ore nickel ore and other ores as wel l as and can be used after ball mills in a grin ding process like Iron Ore Ball Mill Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steelBall Mill an overview ScienceDirect TopicsA ball diameter that grabs the particle must exceed the particle by 25 times to achieve this semiself locking taper One can argue the f50 is a more realistic value since balls wear and the average ball size might be closer to half the maximum Then the multiple would be closer to 13 times the maximum particle size fed to the ball millFeed Size VS Ball Size Grinding Classification

Investigation on the particle size and shape of iron ore

An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied The particle size distribution was meticulously examined by sieve, laser and image analyses To measurewhere d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall Mills an overview ScienceDirect Topics Investigation on the particle size and shape of iron ore pellet feed using ball mill and HPGR 909 areas of 500–1600 cm2 g1 The concentrate must therefore be reground in order to prepare suitable pellet feed High pressure grinding roll (HPGR) and ball mill are the most widely usedInvestigation on the particle size and shape of iron ore

[PDF] Investigation on the particle size and shape of

An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied The particle size distribution was meticulously examined by sieve, laser and image analyses To measure the specific surface area of particles, BrunauerEmmettTeller (BET) and Blaine methods were usedRolling ball mill has been used to mill the iron mill scale with two different milling periods, which were two hours and six hours After the milling process, the iron mill scale was sieved using sieving machine to a few specified grating sizes Weight of each sample collected from each grating size was calculated in order to get the percentage Study on Milling Periods on the Iron Mill Scale Particle charge in ball mills Tongqing Li 1, Zixin Yin2 and Guiyi Wu3 Abstract Ball mill is the widely used comminution device for the size reduction of iron ore particles, yet the underlying mechanisms of heat transfer and thermal breakage inside the mills heretofore are not deeply understood Therefore, theAdvances in Mechanical Engineering 2021, Vol 13(3) 1–9

Ball Grinding Mill at Best Price in India

Ball Mill for Iron ore benefication: A Ball Mill a type of grinder is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumWet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmWet Grid Ball Mill Rhyther Mining Mini vertical planetary ball mill is an ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratory which needs to acquire four samples in one experiment Feed Size: Soft and crispy materials ≤ 10mm PTFE mill jar Iron ore materials or other materials with low impurity sensitivityMini Planetary Ball Mill Lab ball mills,Lab Powder

balls capable of grinding the feed in a ball mill gives

balls capable of grinding the feed in a ball mill gives the maximum efficiency a) Cast iron b) Minimum size c) Maximum size d) Elliptical finer particle size in the overflow, there is thus less material in the overflow This implies more material in the underflow, which is the fresh feed to the second ball mill If circulating load in the second ball mill is kept constant, any variation in the fresh feed will ultimately be reflected in the product particle size of Cyclone 2Grinding control strategy on the conventional milling Ball mill grinding machine is a kind of horizontal drumtype grinding mill with external gear and double bins Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specificationsSteel balls are taken to a certain height by centrifugal force from drum rotation and then fallEnergy Saving Ball mill,Ball grinder,Ball grinding mill

Stirred mills for wet grinding Outotec

Stirred media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products SMD’s feed size is typically 80% passing 100 µm and finer, but it can also handle coarser materials in various applications The mill heads are insured against breakage due to the high tensile strength of cast steel as compared to that of the cast iron head found on the ordinary rod mill Trunnion Bearings are made of highgrade nickel babbitt, dovetailed into the casting Ball and socket bearings can be furnished if desired Buy a Rod MillRod Mills Mineral Processing Metallurgy Analysis of particle size distribution for open and closedcircuit ball mills feed and product showed that d 90 value of feed and product of opencircuit mill is 4383 and 4233 microns A process mineralogy approach to study the efficiency

Advances in Mechanical Engineering 2021, Vol 13(3) 1–9

charge in ball mills Tongqing Li 1, Zixin Yin2 and Guiyi Wu3 Abstract Ball mill is the widely used comminution device for the size reduction of iron ore particles, yet the underlying mechanisms of heat transfer and thermal breakage inside the mills heretofore are not deeply understood Therefore, the Mini vertical planetary ball mill is an ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratory which needs to acquire four samples in one experiment Feed Size: Soft and crispy materials ≤ 10mm PTFE mill jar Iron ore materials or other materials with low impurity sensitivityMini Planetary Ball Mill Lab ball mills,Lab Powder balls capable of grinding the feed in a ball mill gives the maximum efficiency a) Cast iron b) Minimum size c) Maximum size d) Ellipticalballs capable of grinding the feed in a ball mill gives

Sustainable way of Pelletization Metal Bulletin

• Mill feed • Ball mill current • Mill Sound level dB • Mill filling level • Ball mill Grinding Media size • Roksh RPM • Mill discharge, Bag filter inlet and outlet draft • Mill rejects • Iron Ore fines • Limestone • Olivine • Nut Coke/ coke breeze / Anthracite Input Output Ground Ore Concentrate • Blaine number ( cm2/gm ) finer than 3 mm (which is supposed to have a lower iron content and higher sulfur and phosphor grades) An Auto Genius mill and a secondary crusher are considered in this area Ore coming from the size reduction section is fed to the dry low magnetic separator (LMS) and dry high magnetic separator (HMS) in the order depicted in 1Discrete Event Simulation of an Iron Ore Milling Process beneficiation of Itakpe (Nigeria) iron ore achieved through jigging operations Iron ore obtained from Itapke Iron Ore Mining Project, Kogi State, Nigeria which contains a very high amount of quartz as revealed by xray diffraction was crushed using the laboratory dodge crusher and ground in a laboratory ball mill Particle size analysis was Effectiveness Of Gravity Concentration For The

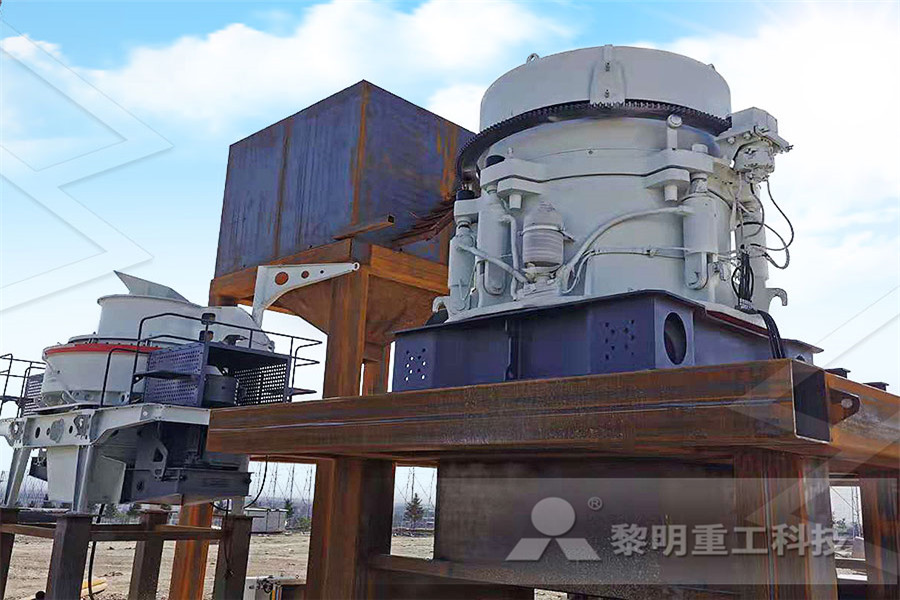

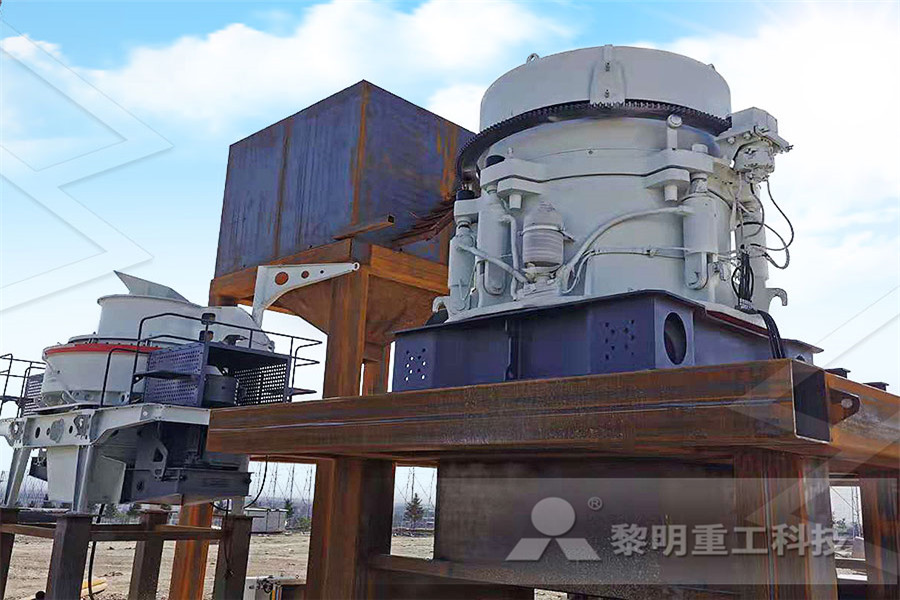

Ball Mill, Model of Ball Mill, Rod Mill, Manufacturer of

Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable ・Widely applied from carbon mold steel to stainless steel, cast iron aluminum alloy Mar 2020: Serie expansion, “new shoulder milling insert” ZOMTPL type for QM MILL 630MB ・QM MILL have extensive lineup (PL breaker shoulder milling insert from semifinishing to finishing side DIJET INDUSTRIAL CO, LTD|New Products

Difference Between Iron Ore And Iron Sands

crusher plant at ropar punjab

gypsum gypsum mining mpanies in kenya

Conveyor Belts In Century

Stone Crushing Plant Cap 500 Tph Flow Chart

crushing plant funding requirements

pyrometallurgy microwave in minerals processing and metallurgy

dealer of potable stone stone crusher in chandigarh and photo

how to mount a vibrating screen

building demolisher crusher machine

silica silica quartz grinding machine

limestone portable crusher price in india

gravel screener for sale and crusher

roll crusher crusherdouble

stone crusher in 100tph plant

limestone limestone crusher plant in india

no of crushers required in cement plant

impact crusher crushercrushing

principle of roller mill

the principle of crusher run

Raw Material In Cement Production

equipment needed for mining iron ore

attachment rock crusher for sale

parts of sinter crusher ussr

Mining and aggregate Plant In Mexi

DXN crusher plant tph

made india dolomite grinding machine stone crusher machine

old stone crusher sale in district

grinding iron oxide powder

indian standard for crusher produced aggregate